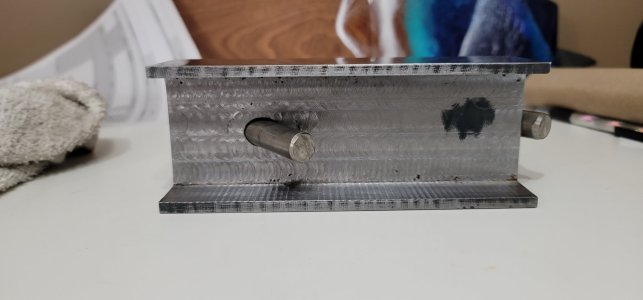

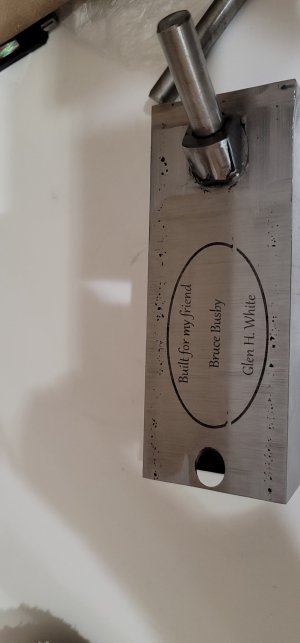

well i made my first project on the mill my friend needed a jig to drill holes in a banister he is building so i made a jig that has a 1in rod with a half in hole to drill through and a hole for a locating pin used a 1x2 tubing welded 1/4 in plate on the sides drilled the rod and finished at 37deg then bored a 1in hole at 37deg through the tubing and milled off all welds to make it smooth

i should have taken more time to clean before tig welding it as I couldn't make a clean weld

tell me what you think

i should have taken more time to clean before tig welding it as I couldn't make a clean weld

tell me what you think