-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Product Fine tooth hole saw?

- Thread starter David

- Start date

Product

Former Member

Guest

Try

Price wise they are good (you can pay a lot more but nothing is gained other than spending more money).

Secret is using good rigidity for both the bit and the work pc. Consent speed (not too fast) and easy feed, let it do the work.

It was an expensive lesson to learn all this.

Price wise they are good (you can pay a lot more but nothing is gained other than spending more money).

Secret is using good rigidity for both the bit and the work pc. Consent speed (not too fast) and easy feed, let it do the work.

It was an expensive lesson to learn all this.

That carbide looks coarser than the typical coarse tooth bi-metal? I know I've seen 'fine teeth' in the big box stores Makita? Dewalt? Lennox? but just not landing on them. The regular bi-metal work surprisingly well but I they really need to have both part & drill supported vs freehand & use the center pilot drill if you can, especially where you initially only have partial contact

Attachments

what are you using to notch with ? i have notched quite a bit of pipe with one of these cheap notchers and standard bi metal hole saws with no problems

I have a whole set of those carbide cutters and they work amazing. The problem with my set is they are only 1/2" deep so are only really good for thinner materials.That carbide looks coarser than the typical coarse tooth bi-metal? I know I've seen 'fine teeth' in the big box stores Makita? Dewalt? Lennox? but just not landing on them. The regular bi-metal work surprisingly well but I they really need to have both part & drill supported vs freehand & use the center pilot drill if you can, especially where you initially only have partial contact

View attachment 38300View attachment 38298

Just a hole saw in my mill...what are you using to notch with ? i have notched quite a bit of pipe with one of these cheap notchers and standard bi metal hole saws with no problems

What on earth is that???

LOL - I was dumpster diving at Boeing Surplus many years ago when they were scrapping a plant in Kent.What on earth is that???

This is one of their precision hole saws used for cutting holes in titanium airframes. It is 8" long and much harder than a file.

Cuts a LOVELY hole!

Question really should be - why on earth do I have that?

Amazing!LOL - I was dumpster diving at Boeing Surplus many years ago when they were scrapping a plant in Kent.

This is one of their precision hole saws used for cutting holes in titanium airframes. It is 8" long and much harder than a file.

Cuts a LOVELY hole!

Question really should be - why on earth do I have that?

Just a hole saw in my mill...

You might just not have the speed and pressure dialed in, that should do a much better job than the cheap tube notcher i use with a cordless drill on the back of the truck.

some of the higher end tube notchers use a big endmill and geed the tube into the side of the endmill....although i dont imagine you want to buy an endmill that big

the other alternative is just make 2 30 dege cuts on the end of the pipe like this /\ and a quick touch up with the grinder makes a satisfactory cope for a mig

I may end up doing it freehand as I only have to make two angled copes.You might just not have the speed and pressure dialed in, that should do a much better job than the cheap tube notcher i use with a cordless drill on the back of the truck.

some of the higher end tube notchers use a big endmill and geed the tube into the side of the endmill....although i dont imagine you want to buy an endmill that big

the other alternative is just make 2 30 dege cuts on the end of the pipe like this /\ and a quick touch up with the grinder makes a satisfactory cope for a mig

Former Member

Guest

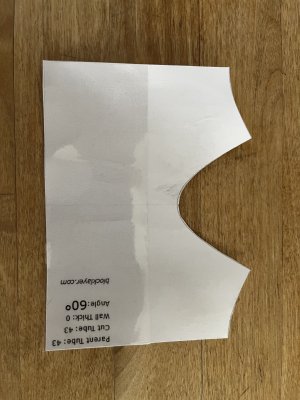

The other way is lay it out with paper, lay it on the tube and hand grind the line.

I wish I had an 1.75” annular cutter!Have you ever tried annular cutters. They beat a hole saw by a country mile for smaller holes.

They will actually cut a hole where one side comes out of the metal without any effort.

Former Member

Guest

Here's something you may want to see.

Likewise I found Garage Fab on YT. Had a great tutorial.Here's something you may want to see.

Rauce

Ultra Member

I’ve notched a lot of thin tubing having made a lot of bicycle frames. I use mostly Morse hole saws and they are reasonably fine pitch. I got mine from McMaster-Carr. If you can find them, the discontinued Starrett constant pitch ones are good too.

Make yourself a more rigid arbor on the lathe. Just a 3/4” bar with a 5/8”-18 thread on the end.

Heavy cutting lube and slow speeds. I mostly use saws in the 1-2” range and run them at 150-400rpm

Make yourself a more rigid arbor on the lathe. Just a 3/4” bar with a 5/8”-18 thread on the end.

Heavy cutting lube and slow speeds. I mostly use saws in the 1-2” range and run them at 150-400rpm