After a period of difficulty, I have finally managed to register with this site thanks to the support and patience of members trlvn and Susquatch, both of whom I thank for their assistance.

I am a self-taught bungler from the Belleville, Ontario area with no technical background whatsoever; I do, though, enjoy trying to make little steam models using plans from magazines and other sources. Some work, some don't....

I also like finding "project" or incomplete models and wreaking havoc on them.

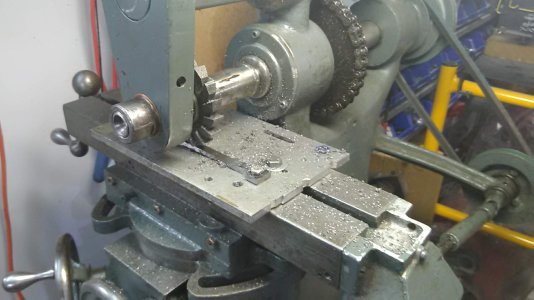

Things in my little shop include a Logan Model 200 lathe, a Craftex B2071 lathe/mill, a Burke #4 horizontal milling machine, a Sherline lathe, a Sherline milling machine, a cheap drill press, a Cameron precision drill press, a 1" belt/disc sander, a 14" wood/metal bandsaw, and one of those ubiquitous offshore 4x6 horizontal/vertical metal band saws. Most of these came over the years from yard sales, chance discoveries, or the local dump. Of course, I have the usual assortment of hand and measuring tools, again gleaned from various sources.

Though I don't think that I can contribute much of value to this forum, I do hope to learn machining methods and learn of others' projects and experiences.

Thank you for allowing me to participate.

I am a self-taught bungler from the Belleville, Ontario area with no technical background whatsoever; I do, though, enjoy trying to make little steam models using plans from magazines and other sources. Some work, some don't....

I also like finding "project" or incomplete models and wreaking havoc on them.

Things in my little shop include a Logan Model 200 lathe, a Craftex B2071 lathe/mill, a Burke #4 horizontal milling machine, a Sherline lathe, a Sherline milling machine, a cheap drill press, a Cameron precision drill press, a 1" belt/disc sander, a 14" wood/metal bandsaw, and one of those ubiquitous offshore 4x6 horizontal/vertical metal band saws. Most of these came over the years from yard sales, chance discoveries, or the local dump. Of course, I have the usual assortment of hand and measuring tools, again gleaned from various sources.

Though I don't think that I can contribute much of value to this forum, I do hope to learn machining methods and learn of others' projects and experiences.

Thank you for allowing me to participate.