I didn't want to derail the "Garage heater install" thread so I've started a new one.

Some of you have probably been thru this and may have answers or info to share.

My house is an older house from around 1940. Small panel with the meter inside the house. The insurance company uses this excuse to justify their high policy premiums.

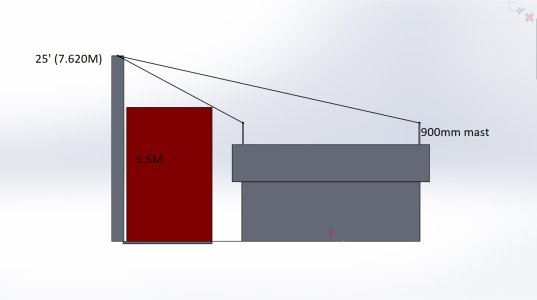

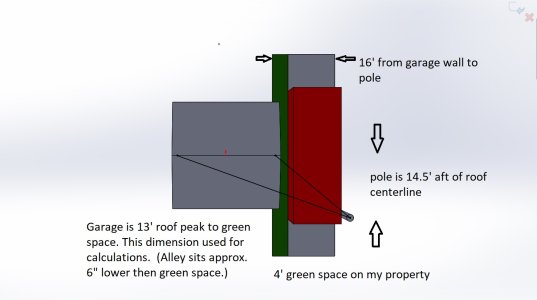

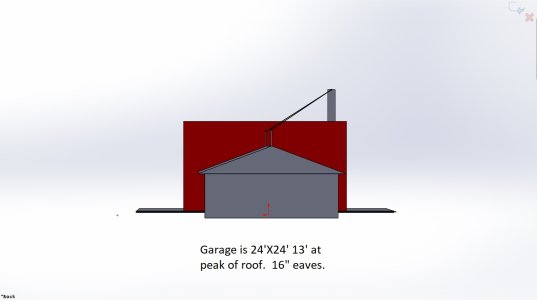

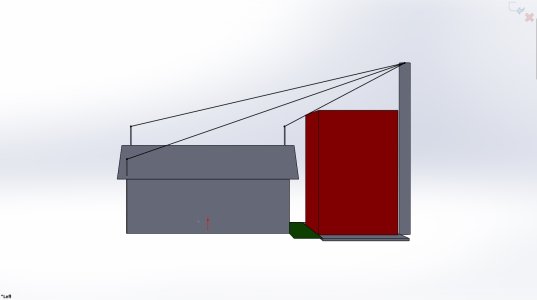

I've built a new 24' x 24' garage and it will be needing power. So the plan was to install a new panel in the garage and feed a sub panel to power the house. (The insurance company will need another excuse.)

The estimator was here today. Just thinking over what we talked about and I think I remember him saying the feeder from the garage to the house panel will be aluminum.

Reading on the web it says it can be either copper or aluminum. Pros? Cons?

Also he suggested a 100 amp service in the garage. If you go larger you need to contact Enmax to confirm that the transformer in your area has enough capacity to go with a larger service. Enmax has confirmed I am good for 200 amps? What do I need? I could see a possible electrical vehicle charger down the line. I'm into machining as a hobby and presently work on smaller items but you all know how that goes. (Maybe I'll find a $500 milling machine locally that needs 9'X9'X10' of space. lol )

The panel I have now for the house has six screw in fuses. (90 amp? 6 fuses X15 amp? I'm guessing here.) The dryer and stove are gas . Gas furnace. No other big loads.

Thoughts on panel size?

Just to add to the story , seeing I was digging a trench for the electrical I decided that I might as well run the gas line at the same time. When my friend did his electrical it was a 4" wide trench 20" deep. I was expecting the same. My trench needs to be 18" wide 20" down. The gas and electrical need 12" of seperation.

Haven't got the actual cost of this yet, but I'm sure it won't be cheap.

Some of you have probably been thru this and may have answers or info to share.

My house is an older house from around 1940. Small panel with the meter inside the house. The insurance company uses this excuse to justify their high policy premiums.

I've built a new 24' x 24' garage and it will be needing power. So the plan was to install a new panel in the garage and feed a sub panel to power the house. (The insurance company will need another excuse.)

The estimator was here today. Just thinking over what we talked about and I think I remember him saying the feeder from the garage to the house panel will be aluminum.

Reading on the web it says it can be either copper or aluminum. Pros? Cons?

Also he suggested a 100 amp service in the garage. If you go larger you need to contact Enmax to confirm that the transformer in your area has enough capacity to go with a larger service. Enmax has confirmed I am good for 200 amps? What do I need? I could see a possible electrical vehicle charger down the line. I'm into machining as a hobby and presently work on smaller items but you all know how that goes. (Maybe I'll find a $500 milling machine locally that needs 9'X9'X10' of space. lol )

The panel I have now for the house has six screw in fuses. (90 amp? 6 fuses X15 amp? I'm guessing here.) The dryer and stove are gas . Gas furnace. No other big loads.

Thoughts on panel size?

Just to add to the story , seeing I was digging a trench for the electrical I decided that I might as well run the gas line at the same time. When my friend did his electrical it was a 4" wide trench 20" deep. I was expecting the same. My trench needs to be 18" wide 20" down. The gas and electrical need 12" of seperation.

Haven't got the actual cost of this yet, but I'm sure it won't be cheap.