ForumFrog

Ian

I got my first lathe: a colt-720g, took the headstock apart to clean, then realized that the adjustment nut for reassembly is MIA. I'm in a pickle and need someone to machine the nut so I can get back to learning to machine!

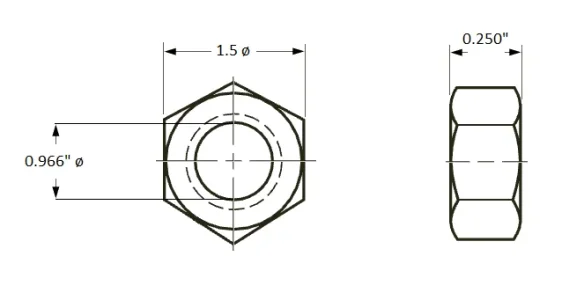

There's absolutely no information about these lathes or the original part and its dimensions so I can only provide the thread measurements as I've taken them from the spindle.

-0.966" major thread diameter on the spindle

-18 TPI

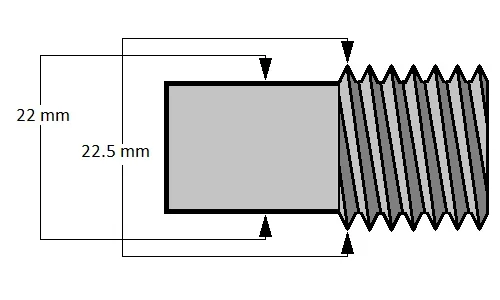

I'd like to get something like the part diagram I included. I'm an absolute novice so the dimensions are not set in stone and ideally if someone's willing to help I can meet up and we can confirm the part dimensions with the spindle. I'm just not confident in my novice eye to send this off to be made.

If someone's willing to help then you can inbox me a quote and we can figure it out.

Thanks

There's absolutely no information about these lathes or the original part and its dimensions so I can only provide the thread measurements as I've taken them from the spindle.

-0.966" major thread diameter on the spindle

-18 TPI

I'd like to get something like the part diagram I included. I'm an absolute novice so the dimensions are not set in stone and ideally if someone's willing to help I can meet up and we can confirm the part dimensions with the spindle. I'm just not confident in my novice eye to send this off to be made.

If someone's willing to help then you can inbox me a quote and we can figure it out.

Thanks