Thanks for those documents and info Gerrit, I would appreciate it if you could provide the dimensions of the flange washers. The belt with my machine is a toothed timing belt of some kind, run with the teeth facing out. The dimensions you provided will help me track down a correct one.Here's the manual and a drawing of the chuck. I haven't made the chuck yet. I can measure the wheel washers if you like.

I bought new brushes from Asia, had to file one side down slightly for it to fit. Belts were ordered from the UK: https://beltingonline.com 12.5mm wide, 420 mm long. New bearings purchasesd from https://bocabearing.com although they have rubber seals so heat up at the high RPM setting. If I use it at that speed I will be removing the seals and going back to oil in the housing. I couldn't find metal seal bearings, the originals were open on both sides. They also have the motor bearings. Shipping is $0 from US!

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dumore tool post grinder adapted to use Sioux valve seat grinding stones

- Thread starter John Conroy

- Start date

The belt with my machine is a toothed timing belt of some kind, run with the teeth facing out.

This is very curious to me John. What in the world is the purpose of facing the teeth out? On the surface that would appear to negate the timing aspect and probably accelerate belt wear too.

These are driven by flat belts. Dumore hasn't sold this belt for a long time. I suppose sometmes any belt is better than no belt.

I see, so basically you are suggesting that a reversed timing belt was used to substitute for a flat belt that was no longer available and the timing feature isn't used.

The back side of a timing belt isn't very durable. It's not designed to run against a pulley of any kind. When one is located, I'd be tempted to buy a box of them.....

gerritv

Gerrit

its just plain wrong to do this. A flat belt conforms slightly to the crown of the pulley, thus tracking properly. And it is considereably more flexible than a toothed belt.

I bought 2 just in case but seeing how they are constructed I can't imagine wearing one out. The original Dumore ones might be flimsier, never seen one. I know that at Univac we used a lot of flat belts for driving pulleys on card sorters and readers. Nothing like merging 2 sets of cards at 1000 cpm each into a centre pocket.

I bought 2 just in case but seeing how they are constructed I can't imagine wearing one out. The original Dumore ones might be flimsier, never seen one. I know that at Univac we used a lot of flat belts for driving pulleys on card sorters and readers. Nothing like merging 2 sets of cards at 1000 cpm each into a centre pocket.

gerritv

Gerrit

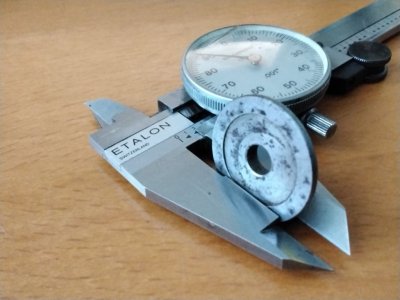

5/32" thick, 1.044" diameter. there is a recess 0.015" deep, .77" diameter on one side (side where it touches the grinding wheel). Other side has a tapered face. Hole is 0.250" diameter, should be a close fit on the shaft. Everything should be concentirc to avoid imbalance.Thanks for those documents and info Gerrit, I would appreciate it if you could provide the dimensions of the flange washers. The belt with my machine is a toothed timing belt of some kind, run with the teeth facing out. The dimensions you provided will help me track down a correct one.

Attachments

its just plain wrong to do this. A flat belt conforms slightly to the crown of the pulley, thus tracking properly. And it is considereably more flexible than a toothed belt.

Yup. Now have a boo at the fabric material used on the back of a timing belt. It won't last long!

Thanks again Gerrit. The inside out toothed belt actually runs very smoothly and conforms to the crowned pulleys well but since this grinder has no belt guard I think a correct belt is in order.LoL

RobinHood

Ultra Member

I would contact Transmission Supply Edmonton for the flat belt. This is where I got mine for the Dumore #44 and the Clarkson T&C Grinder. (The Calgary branch actually - but the belts were in stock in Edmonton, so they shipped them here). I basically just gave them the dimensions and they cut them off of stock material (to any width you want). Runs very smoothly and seems very durable. Megadyne / Jason, made in Italy. Very good price too.

The first picture is the original Dumore belt; the second is of the equivalent replacement.

Here is the old and new belt to the Clarkson T&CG.

The first picture is the original Dumore belt; the second is of the equivalent replacement.

Here is the old and new belt to the Clarkson T&CG.

This belt issue comes up a lot with Themac TPGs as well, although the belts are still available for current models. They are very thin & have some kind of fiber in them very similar to @RobinHood pics.

Supposedly the low mass & material factors in them staying put at speed & not transmitting vibration into the spindle. I've heard or read that 'regular' belts (whatever that means) start to arc & stretch under their own weight at TPG like rpm/pulley conditions or develop harmonics. Supposedly vacuum cleaner belts are similar but who knows about size & equivalent power, configuration etc.

Supposedly the low mass & material factors in them staying put at speed & not transmitting vibration into the spindle. I've heard or read that 'regular' belts (whatever that means) start to arc & stretch under their own weight at TPG like rpm/pulley conditions or develop harmonics. Supposedly vacuum cleaner belts are similar but who knows about size & equivalent power, configuration etc.

I've wanted a TPG for a while now, and won this guy tonight. Model 8119, catalog number 31-011, 1/5th hp. Is that similar to yours @John Conroy, @RobinHood ?

I found the manual: http://vintagemachinery.org/pubs/detail.aspx?id=19657

It says 8-11 inch swing. I'm hoping it will work ok with my 13" Emco.

#586 Dumore Tool Post grinder in case NICE!! 31-011 | eBay

READ THIS! I AM hard to get ahold of --but am reachable. You generally won't be able to reach us on weekends. We work gun shows, and try to travel then. WE WILL send you a combined invoice.

www.ebay.com

I found the manual: http://vintagemachinery.org/pubs/detail.aspx?id=19657

It says 8-11 inch swing. I'm hoping it will work ok with my 13" Emco.

It looks very similar to my model 11, maybe yours is newer. Mine doesn't even have a switch, you just unplug to turn it off. The specs on your motor are the same as mine. I found a local source for belts and ordered 3. I'll report on them when they arrive.

If I recall, you have a 14" swing machine @John Conroy ?

That's right. I used shims to get the TPG spindle on center with the lathe spindle

Awesome, Thank you for the pics.

I almost won another TPG a while back but i'm glad I didn't. I think it was 1/2hp and it weighed like 60 lbs, so i think it would have been much too large.

I want to make a D1-4 camlock rotary table adapter and after the Mr Crispin video, I see that grinding is probably the way to go.

I almost won another TPG a while back but i'm glad I didn't. I think it was 1/2hp and it weighed like 60 lbs, so i think it would have been much too large.

I want to make a D1-4 camlock rotary table adapter and after the Mr Crispin video, I see that grinding is probably the way to go.

That's right. I used shims to get the TPG spindle on center with the lathe spindle

Hey John, just wondering about a few things.

Given that both the lathe and the grinder are cylindrical devices, does it really matter if the grinder axis isn't the same exact height as the lathe? I would think +/- 20 degrees or so would work just fine. I chose a degree qualifier simply to take into account the height impact of a smaller diameter part.

I notice that your belt appears to be a backward timing belt. I believe you previously mentioned that, but I don't recall if you told us how well the belt backing fabric is holding up.

I'm not sure if there would be a problem running the TPG spindle at a different height that the lathe. The instruction manuals I read on the Dumore site all say they must be the same height. I suspect the TPG bracket that sits on the compound is designed to be loaded 90 degrees to the compound mounting stud. If the TPG is above or below center the loading would be diagonal and the bracket is not very robust.

The inside out toothed belt tracks perfectly and runs very smooth. In the last week I have run it about 10 hours and have not had a single issue with slipping, tracking or vibration. I think I will attempt to copy the belt guard used on later models as it would be a disaster to get fingers into the belt area when running.

The inside out toothed belt tracks perfectly and runs very smooth. In the last week I have run it about 10 hours and have not had a single issue with slipping, tracking or vibration. I think I will attempt to copy the belt guard used on later models as it would be a disaster to get fingers into the belt area when running.