Martin w

Ultra Member

Why do people not like multi-fix? what bugs you? I briefly used one at SAIT while taking their intro lathe course. I liked it, seemed quick and efficient generally. It did seem to accumulate chips and require cleaning before changing tools. I did not like the 4 post on a lathe I use to own as it rotated unexpectedly when under load e.g. when parting. Maybe that was a poor 4 post? Operator error? I bought a BXA wedge type post and found it much better. I didn't like the price of the tool holders on the multi-fix but found it convenient. So curious why people don't like multi-fix.

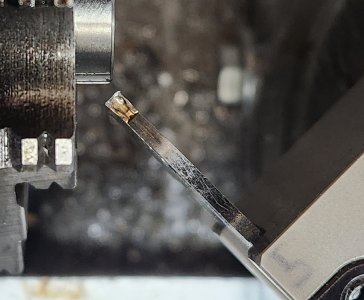

The multifix is not as stout as the 4way. Especially with a large boring bar. I can part off under power with the 4 way toolpost, but not so much with the multifix. I can have 4 tools set up in a 4 way and rotate to different cutting tools easier. Setting tool height is way easier on the multifix. Also easier to change to a different cutting angle or to get closer to a shoulder.

My multifix is a CA size on a 20” swing

Just my opinion. I still keep the multifix on my lathe so it’s not as bad as I make out. Lol