TorontoBuilder

Sapientia et Doctrina Stabilitas

A certain ventilation company makes a product that provides multiple switching options, from the most basic; off,, low and high fan switch, to the more complex arrangements that make the high fan speed controlled by a humidistat, to multiple fan timer options, to recirculation options that actuate a damper to change the airflow pathway...

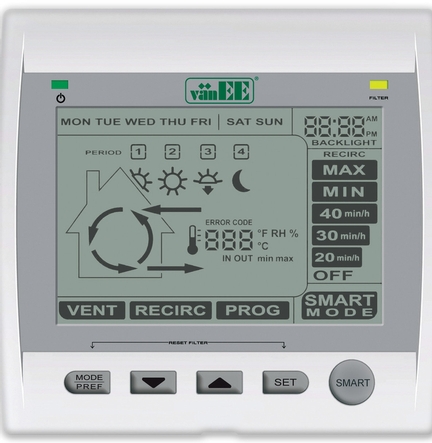

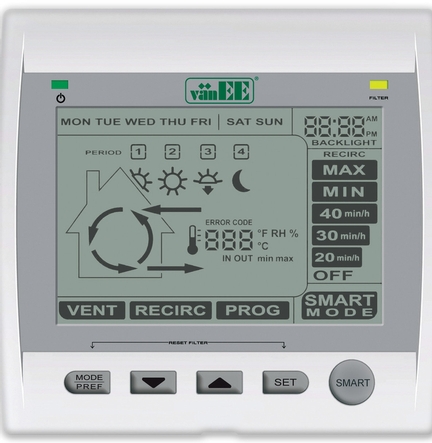

The highest level controller has a full blown lcd screen. It is similar to a programmable thermostat but for ventilation. For all their sophistication however they still require a lot of manual user input if you have changing conditions that require varying the recirculation rates and the lack the ability to know when to override a setting when another setting falls outside set parameters, and they dont have an alarm or alert.

So I want to replace the manufacturers controller with an ESP32 controller that has more settings, options and overrides as well as an alarm function.

I think I can connect an oscilloscope inline with the communications lines going back to the cpu in the ventilation unit to read the digital signals as I change all the settings in order to reverse engineer the code their controller is using.

I think this is viable method to try, any other suggestions? Oh a logic analyzer would likely work too I guess.

The highest level controller has a full blown lcd screen. It is similar to a programmable thermostat but for ventilation. For all their sophistication however they still require a lot of manual user input if you have changing conditions that require varying the recirculation rates and the lack the ability to know when to override a setting when another setting falls outside set parameters, and they dont have an alarm or alert.

So I want to replace the manufacturers controller with an ESP32 controller that has more settings, options and overrides as well as an alarm function.

I think I can connect an oscilloscope inline with the communications lines going back to the cpu in the ventilation unit to read the digital signals as I change all the settings in order to reverse engineer the code their controller is using.

I think this is viable method to try, any other suggestions? Oh a logic analyzer would likely work too I guess.