I can't really comment on Mach3 - never used it. But fundamental troubleshooting techniques apply.

Start with just one axis plugged in and powered on. Try to get it going. Any movement at all or moves and then faults? How did you configure the drives, and Mach3?

If I recall correctly - I think my stepper motor wires were not the same color coding as the manual and I had to figure that out myself, basically find the 2 pair - ensure they are wired to A+ A- as one pair and B+ and B- as the other pair. If it still doesn't move swap the polarity of one pair.

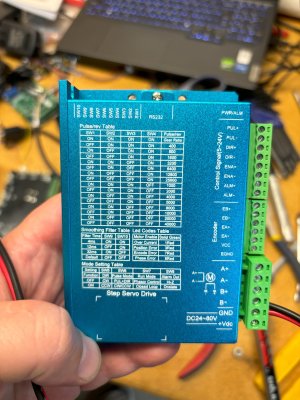

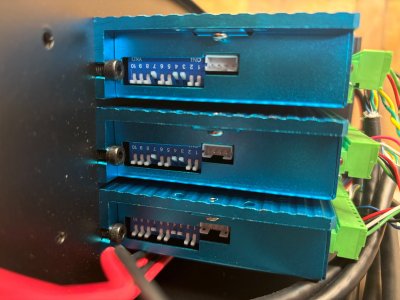

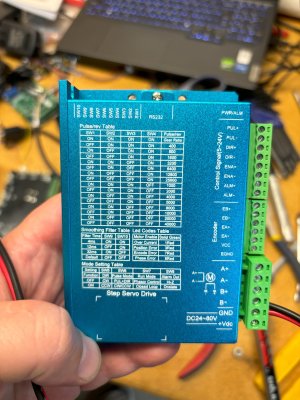

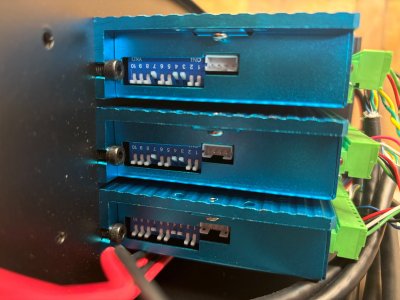

Have you reached out to Shariff? He was pretty responsive to my requests (usually just a few hours). I can take a picture of my rats nest / wiring if that helps....the pictures here are before I was done.

Start with just one axis plugged in and powered on. Try to get it going. Any movement at all or moves and then faults? How did you configure the drives, and Mach3?

If I recall correctly - I think my stepper motor wires were not the same color coding as the manual and I had to figure that out myself, basically find the 2 pair - ensure they are wired to A+ A- as one pair and B+ and B- as the other pair. If it still doesn't move swap the polarity of one pair.

Have you reached out to Shariff? He was pretty responsive to my requests (usually just a few hours). I can take a picture of my rats nest / wiring if that helps....the pictures here are before I was done.