Just got a Mitutoyo dial test indicator and a Mitutoyo dial indicator like new, also in the stuff was a STM dial test indicator that doesn't move at all. Are the STM worth spending time on? Never tore one of these apart, much smaller than farm equipment i usually fix.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dial indicator clean and lube

- Thread starter trlvn

- Start date

Craig, I'm still with Mcgyver on this one. No oil.

"Does it make a difference whether the indicator has jeweled pivot points or not?"

It should. The jeweled pivot points in theory should have less friction, but in real life they can be worn, out of round, cracked, incorrectly installed or sized wrong. Like everything there are different grades.

I've played with a number of watches with no jewels and I'm still amazed at how well they work. I've also worked on watches with too many jewels.

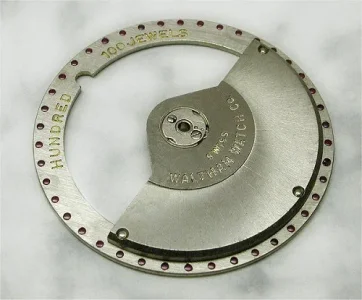

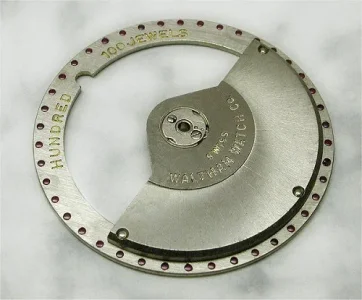

Here is a rotor off a watch with...."100 jewels" and a 21 jewel watch movement. ( 4 extra jewels added to a plate on the ratchet wheel, with room to add another 5 jewels.) These jewels have no function at all. Just there to add to the jewels count in the watch and I guess maybe you could use them as spares?

"Also, I note that Starrett says the following about their tool and instrument oil:

Instrument oil is an extra-fine lubricant made to our specifications and used in our factory to lubricate and protect our precision measuring tools and instruments."

It doesn't say what instruments they are using it on or how. Maybe they are just wiping the surfaces down for a corrosion protection? I could see a light wiping of the plunger and the rack on it, but not in the pivot points.

Try a good cleaning and reassemble dry. If it works all good. If not try the oil. Nothing to loose.

The unit I worked on had two springs. A coiled spring to return the plunger and a hairspring which brings the needle back to the zeroed position.

When pushing in on the plunger the mechanism is coupled with the needle and they move together. When you release the force on the plunger there is a "clutch" that disengages the plunger from the needle. The plunger returns easily under the force of the coil spring. The needle returns under the force of the hairspring. Not a lot of force here. The slightest amount of lubrication added drag to the needle. I tried a number of different watch maker lubricants and I also have access to a wide range of aviation products. Some worked a little better then others but not as good as dry. I also though that the hairspring may have worn out. Tried to come up with a test for that but in the end it worked good dry and the number of cycles on that dry pivot point is so low it made no sense to go any farther.

Sorry, I'm kinda draggin on......

My point in that last paragraph is that the "in plane bearing surface" shown in your photo is most likely on the gear that is driven by the rack. There is probably a heavy spring that is pulling that plunger and rack back.

If I'm looking at your pictures correctly , that plate on the bottom left retains the gear and shaft assembly? More importantly there should be some "endshake" when that plate is installed. The gear and shaft assembly should have a slight amount of play to move between the retained surfaces.

Final tips. After your final cleaning. Assemble off of a lint free surface. Use a loupe or magnifying glass and try to catch all the small little bits of un-seeable pieces of fibers and strands that still find there way inside. It is amazing what makes its way back into a clean assembly. Watchmakers use a puddy called rodico to dab and catch all the little pieces. I'm sure you could improvise.

"Does it make a difference whether the indicator has jeweled pivot points or not?"

It should. The jeweled pivot points in theory should have less friction, but in real life they can be worn, out of round, cracked, incorrectly installed or sized wrong. Like everything there are different grades.

I've played with a number of watches with no jewels and I'm still amazed at how well they work. I've also worked on watches with too many jewels.

Here is a rotor off a watch with...."100 jewels" and a 21 jewel watch movement. ( 4 extra jewels added to a plate on the ratchet wheel, with room to add another 5 jewels.) These jewels have no function at all. Just there to add to the jewels count in the watch and I guess maybe you could use them as spares?

"Also, I note that Starrett says the following about their tool and instrument oil:

Instrument oil is an extra-fine lubricant made to our specifications and used in our factory to lubricate and protect our precision measuring tools and instruments."

It doesn't say what instruments they are using it on or how. Maybe they are just wiping the surfaces down for a corrosion protection? I could see a light wiping of the plunger and the rack on it, but not in the pivot points.

Try a good cleaning and reassemble dry. If it works all good. If not try the oil. Nothing to loose.

The unit I worked on had two springs. A coiled spring to return the plunger and a hairspring which brings the needle back to the zeroed position.

When pushing in on the plunger the mechanism is coupled with the needle and they move together. When you release the force on the plunger there is a "clutch" that disengages the plunger from the needle. The plunger returns easily under the force of the coil spring. The needle returns under the force of the hairspring. Not a lot of force here. The slightest amount of lubrication added drag to the needle. I tried a number of different watch maker lubricants and I also have access to a wide range of aviation products. Some worked a little better then others but not as good as dry. I also though that the hairspring may have worn out. Tried to come up with a test for that but in the end it worked good dry and the number of cycles on that dry pivot point is so low it made no sense to go any farther.

Sorry, I'm kinda draggin on......

My point in that last paragraph is that the "in plane bearing surface" shown in your photo is most likely on the gear that is driven by the rack. There is probably a heavy spring that is pulling that plunger and rack back.

If I'm looking at your pictures correctly , that plate on the bottom left retains the gear and shaft assembly? More importantly there should be some "endshake" when that plate is installed. The gear and shaft assembly should have a slight amount of play to move between the retained surfaces.

Final tips. After your final cleaning. Assemble off of a lint free surface. Use a loupe or magnifying glass and try to catch all the small little bits of un-seeable pieces of fibers and strands that still find there way inside. It is amazing what makes its way back into a clean assembly. Watchmakers use a puddy called rodico to dab and catch all the little pieces. I'm sure you could improvise.

Also Craig, I just watched the Blondie hacks video you linked.

Couple things.

She tries to zero the indicator at the end. If I'm correct the indicator should not go back to zero but approx. 1/4 of gauge travel prior to 0. This allows for a preload on the mechanism when you set it up to use it. (You can/should also preload the coil spring slightly prior to engaging the rack assembly when assembling the unit.)

I think near the end when her needle was not returning correctly (repeatability) to the same reading was not due to the backlash, but due to the drag from the oil she applied. The backlash on the rack and pinion will affect the return of the plunger assembly.

She also uses an alcohol wipe on the crystal. That can cause it to craze. I purposely do this to age crystals to make them look more vintage then they are. I've never heard of the Novus. I use a compound called Polywatch that might be useful for some of the guys here trying to restore the clarity. In reality you can use any fine abrasive and work your way up thru the grades until you get to a crystal clear lens. (for an acrylic lens)

Couple things.

She tries to zero the indicator at the end. If I'm correct the indicator should not go back to zero but approx. 1/4 of gauge travel prior to 0. This allows for a preload on the mechanism when you set it up to use it. (You can/should also preload the coil spring slightly prior to engaging the rack assembly when assembling the unit.)

I think near the end when her needle was not returning correctly (repeatability) to the same reading was not due to the backlash, but due to the drag from the oil she applied. The backlash on the rack and pinion will affect the return of the plunger assembly.

She also uses an alcohol wipe on the crystal. That can cause it to craze. I purposely do this to age crystals to make them look more vintage then they are. I've never heard of the Novus. I use a compound called Polywatch that might be useful for some of the guys here trying to restore the clarity. In reality you can use any fine abrasive and work your way up thru the grades until you get to a crystal clear lens. (for an acrylic lens)

Yup that is my plan, can't resist having a peak under the skirts.@6.5 Fan : if its all seized up - might be worth just the experience to see how it all comes apart. You can't break it any more than it is

Some delicate things are not meant to be looked at you know. They are touchy feely only. You look at stuff like that without a certificate of proficiency from the proper authorities and you might go blind or be turned into a pillar of salt. Just sayin......Yup that is my plan, can't resist having a peak under the skirts.

Kudos, Gentlemen. A very interesting thread doing stuff I am still not comfortable with tackling due to my hands. I have size 23 fingers (ring size).

Had a wee peek under the skirts yesterday, those are some small screws holding things together. Loosened up the screws inside and it works. Had a devil of a time putting those little buggers back in place, sure not like working on a tractor or baler. I don't know if it will last, time will tell.

those are some small screws holding things together. Loosened up the screws inside and it works. Had a devil of a time putting those little buggers back in place, sure not like working on a tractor or baler. I don't know if it will last, time will tell.

6.5, the trick is to use tweezers. Good dumont watchmakers ones. They become an extension of your hand whereas not so good ones add to the frustration. A great deal of success with small work is deftly handling small parts with tweezers, imo its a skill that take some time to develop (I've a ways to go but watch parts don't go "ping" across the room as often as they once did).

here's a watch screw against a 1/4-20 socket head screw. working with them would be close to impossible without tweezers.

here's a watch screw against a 1/4-20 socket head screw. working with them would be close to impossible without tweezers.

Thanks for the tip Mcgyver, arthritis in the fingers doesn't help working with really small stuff either.

On top of arthritis, let's not forget the shakes and bad eyes.

I'm beginning to think that practice in old age doesn't matter anymore. Just dive in and do it. If you wait till you practice enough, everything else will get worse than the improvement and you end up going backwards.

Just git er done @6.5 Fan !