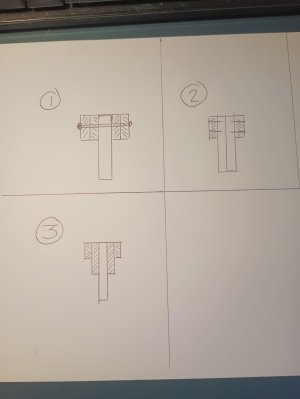

These are your 3 ideas ? Detail 2 is the best, both 1 & 3 add a lot of twisting force to the existing joist, probably ok, but not great. 1 would likely need carriage through bolts to keep that stack together, the other 2 options would be fine with standard .120 hot dipped framing nails

You should also put a membrane on the top of the stack, water will collect on the top and work it's way between, rotting things out over time. They do sell a product specifically for putting on the top of deck joists, I don't recall the name of it