I always have a lot on the go, so i figured i'd start a thread. It'll probably be picture heavy if theres any interest, because everyone loves pictures, right?.

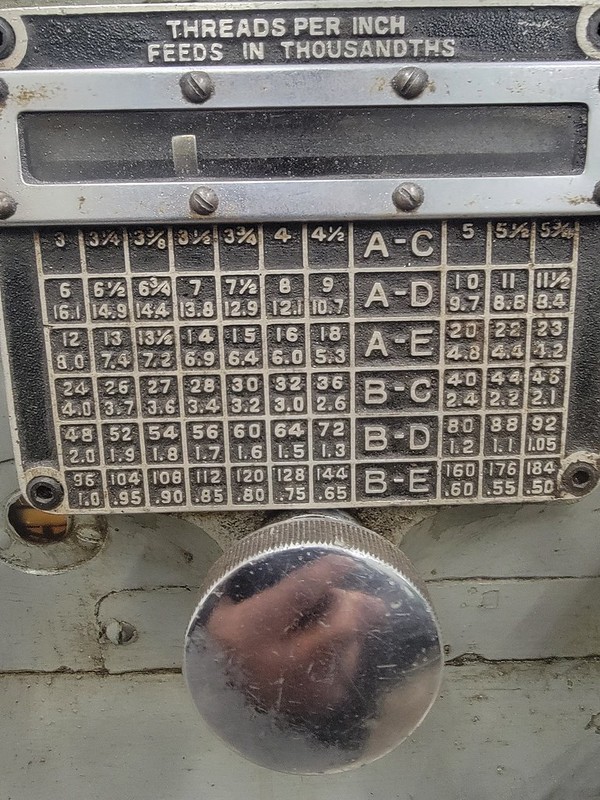

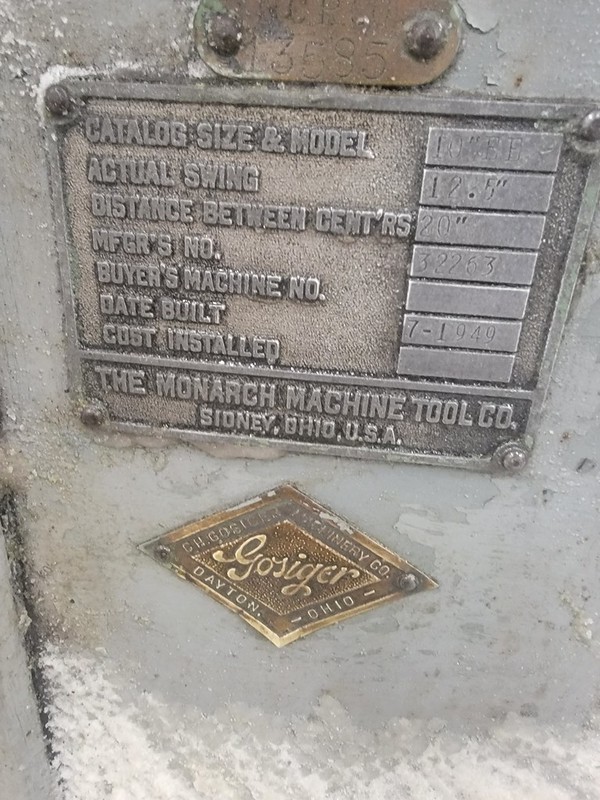

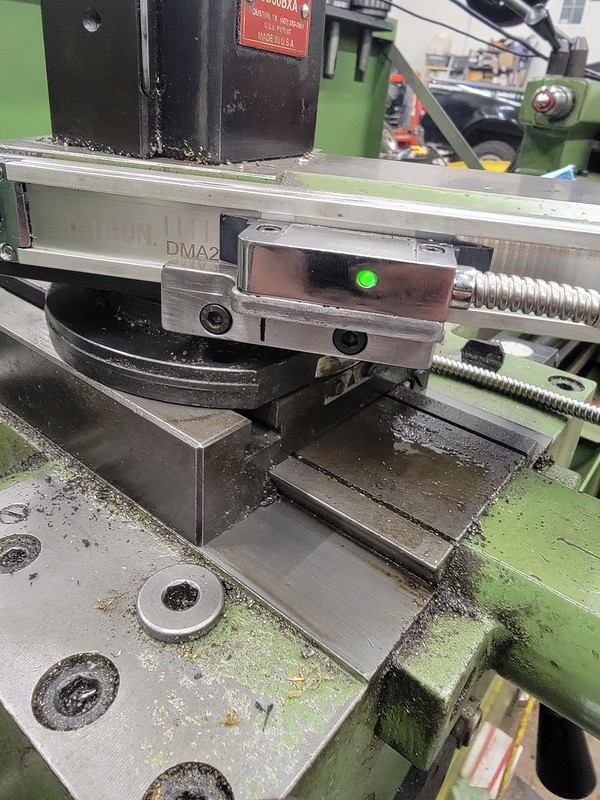

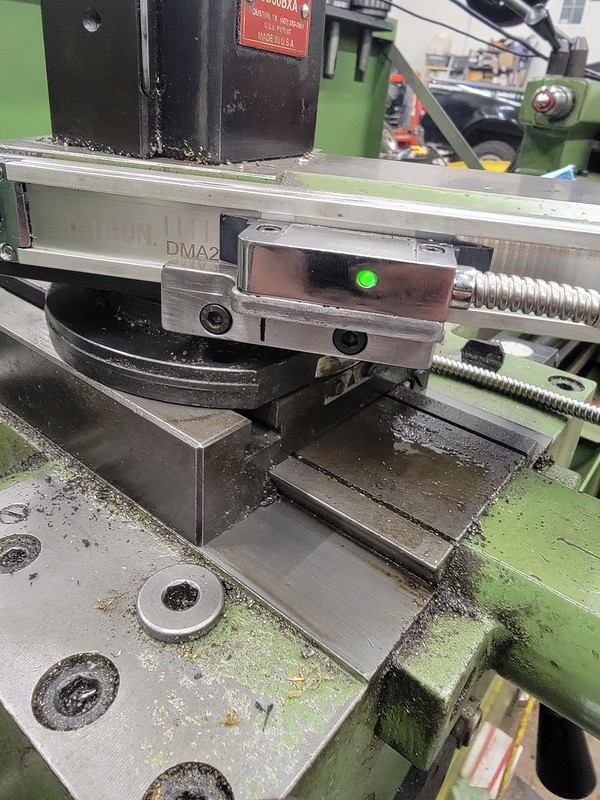

Right now i'm working on installing the new Ditron 3 axis DRO on my Emco V13, so lets start with that. Tomorrow I'm going to pickup my brand new to me Monarch 10ee, which will be a project in itself.

I'm going to add an elbow to the display arm to raise it up and move it back. It interferes with my tool holder rack and is too low for me

This lathe had a DRO on it before, when it lived in the robotics lab. I wanted to reuse the existing holes, as much as possible. The original scale was 2" longer than the new magnetic scale, so i made up an adapter/backer out of 3/16" stainless flatbar. It ate 2 endmills and one tap. Should have bought the aluminum.....

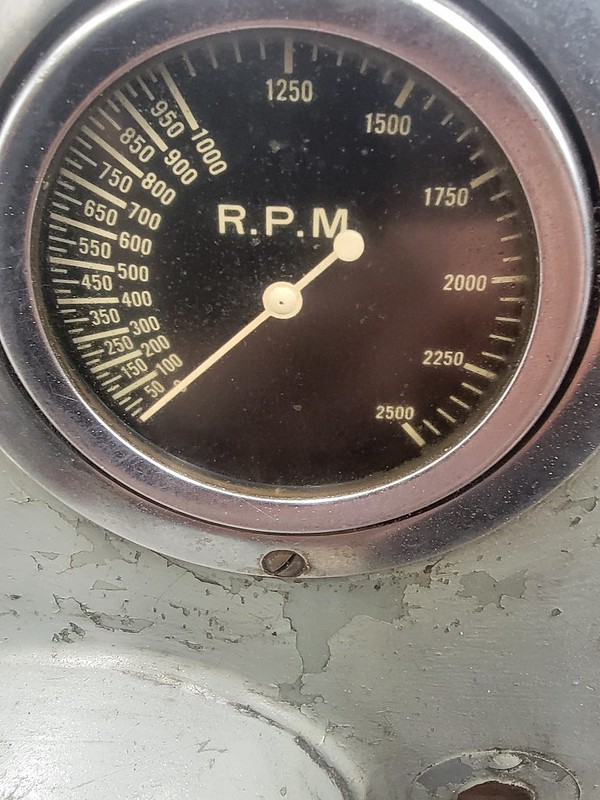

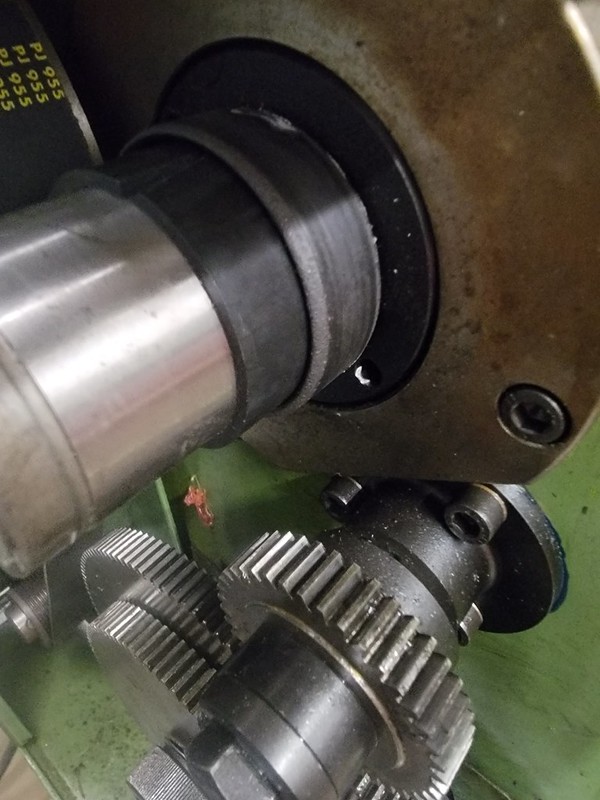

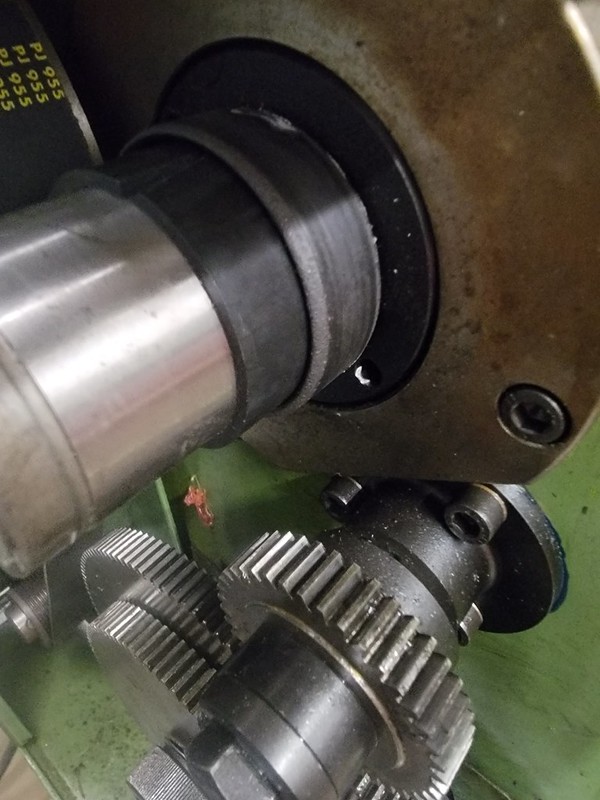

The Ditron D80 has a built in tachometer function, which includes a pickup and a magnet. I took some ABS pipe and bored it to be a tight sliding fit onto the spindle, then drilled a hole for the magnet. I hacked up an ABS coupler to create a ring that would slide over and retain the magnet.

A few drops of crazy glue hold it all together. Its not going anywhere. I left the inner sleeve longer in case i had to add a hose clamp/zip tie

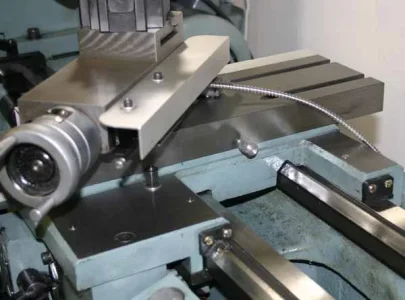

On the compound, i also had to make an adapter. I cut the scale down to make it fit my travel needs. Again, I used the existing holes from the previous DRO install.

Man i need to clean my lathe... Here you can see the existing holes for the reader head mount.

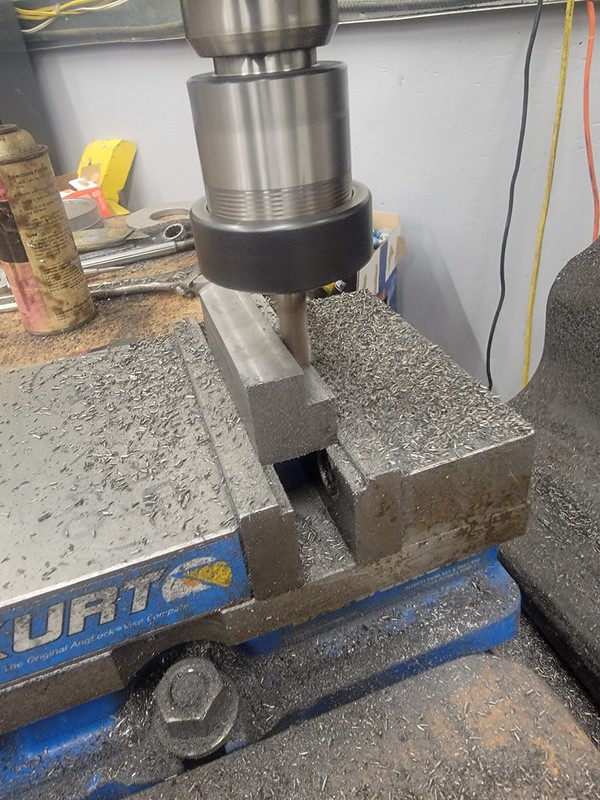

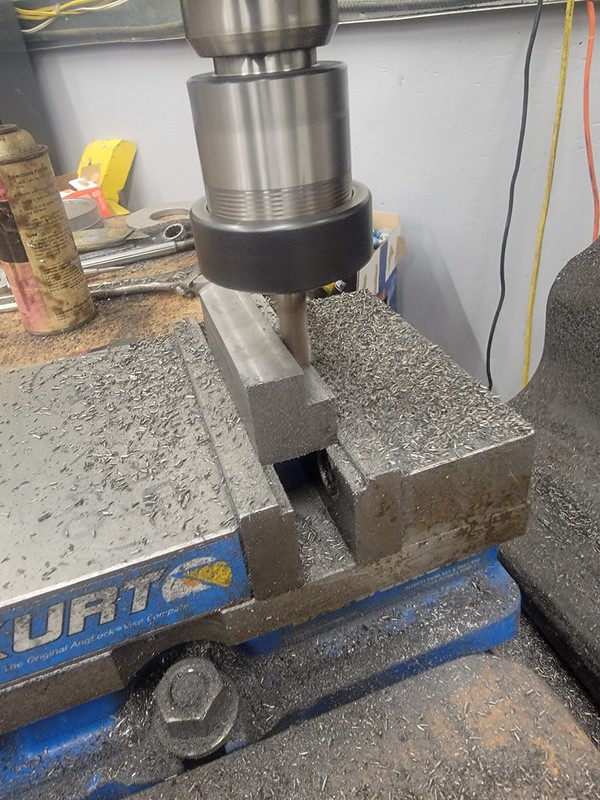

Fortunately I had a chunk of cast iron sitting nearby to make a mount for the reader head.

facemill is a bit faster at hogging off .500"

My pup likes the mill. Extra points if you regognize the voice on the TV in the background

Now i need to work on cable management and guarding. The compound scale presents some challenges for cable management, but i have a plan. Guards will be aluminum and leather.

More to come.

Right now i'm working on installing the new Ditron 3 axis DRO on my Emco V13, so lets start with that. Tomorrow I'm going to pickup my brand new to me Monarch 10ee, which will be a project in itself.

I'm going to add an elbow to the display arm to raise it up and move it back. It interferes with my tool holder rack and is too low for me

This lathe had a DRO on it before, when it lived in the robotics lab. I wanted to reuse the existing holes, as much as possible. The original scale was 2" longer than the new magnetic scale, so i made up an adapter/backer out of 3/16" stainless flatbar. It ate 2 endmills and one tap. Should have bought the aluminum.....

The Ditron D80 has a built in tachometer function, which includes a pickup and a magnet. I took some ABS pipe and bored it to be a tight sliding fit onto the spindle, then drilled a hole for the magnet. I hacked up an ABS coupler to create a ring that would slide over and retain the magnet.

A few drops of crazy glue hold it all together. Its not going anywhere. I left the inner sleeve longer in case i had to add a hose clamp/zip tie

On the compound, i also had to make an adapter. I cut the scale down to make it fit my travel needs. Again, I used the existing holes from the previous DRO install.

Man i need to clean my lathe... Here you can see the existing holes for the reader head mount.

Fortunately I had a chunk of cast iron sitting nearby to make a mount for the reader head.

facemill is a bit faster at hogging off .500"

My pup likes the mill. Extra points if you regognize the voice on the TV in the background

Now i need to work on cable management and guarding. The compound scale presents some challenges for cable management, but i have a plan. Guards will be aluminum and leather.

More to come.

Last edited: