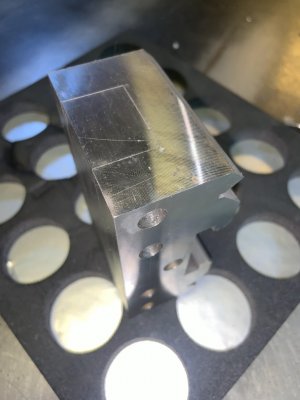

Blank size: 125*70*50

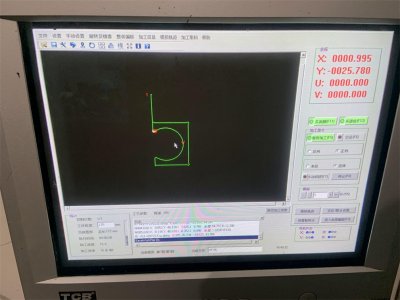

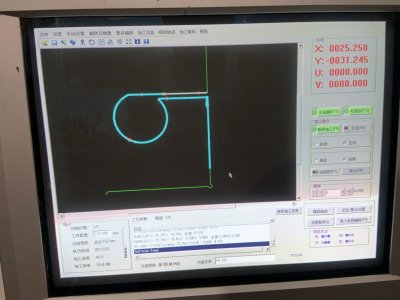

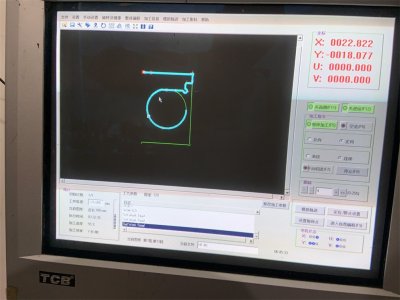

Cutting T slot +V slot, an area of about 14000m square meters, takes 4 hours.

Milling machine drilling

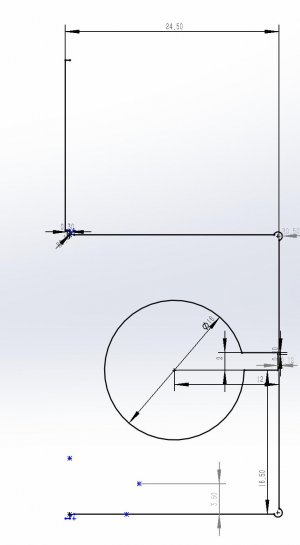

Rectangular slot cutting, area: 10000m square meters, estimated about 3.5 hours (can be completed in about an hour)

It is basically consistent with the estimated time, and the cutting effect is OK, which can confirm that the control logic circuit of the EDM machine tool is correct. Simple cleaning.

Round hole chamfer.

Finish thread

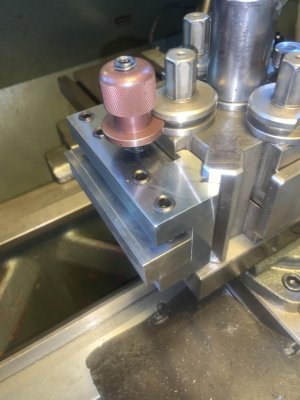

assemble Installation test

Paint the base contact surface Fit test

The outside fit is very good, and the middle two surfaces have less contact area - it will be corrected in the grinding machine processing after heat treatment

Cutting T slot +V slot, an area of about 14000m square meters, takes 4 hours.

Milling machine drilling

Rectangular slot cutting, area: 10000m square meters, estimated about 3.5 hours (can be completed in about an hour)

It is basically consistent with the estimated time, and the cutting effect is OK, which can confirm that the control logic circuit of the EDM machine tool is correct. Simple cleaning.

Round hole chamfer.

Finish thread

assemble Installation test

Paint the base contact surface Fit test

The outside fit is very good, and the middle two surfaces have less contact area - it will be corrected in the grinding machine processing after heat treatment

Last edited: