trlvn

Ultra Member

Crappy online pictures:

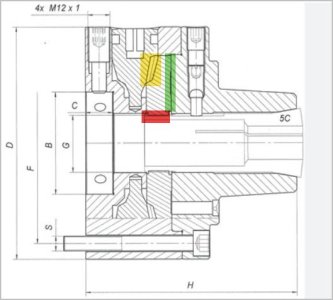

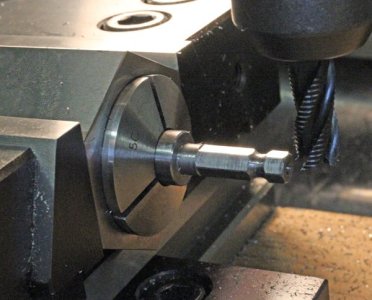

Am@zon kept showing me 5C collet chucks at lower and lower prices until I finally took a flyer. "Findmall" brand. It arrived in 2 days (no Prime) and it looked good. Super smooth ground finish and virtually impossible to see the line between the upper and lower halves of the body.

I took it apart and there was some fine swarf that fell out. The usual filthy brown 'grease'. The parts looked good on the inside though too. The pinions and ring gear that tighten a collet into the chuck *look* fine.

After cleaning, lubricating and reassembling the parts, the trouble started. The chuck would turn freely _until_ I tried to tighten a collet. I had to press the collet into the chuck a little to get it to start threading. Within a few turns, it would get very hard to turn the T-handle. Then it would free up and turn easily for a couple of turns of the handle. Eventually it would get too hard to turn--before the collet was fully engaged in the taper.

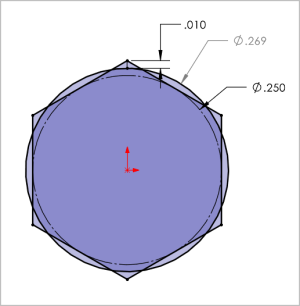

I havent measured to verify but I believe the threaded hole in the ring gear is slightly eccentric. As the collet is drawn in, the tolerances stack up so the collet binds against the front body of the chuck. Note that the ring gear rotates smoothly as long as no collet is engaged. Also, I verified that a collet will easily thread into the ring gear while disassembled.

So I'm returning this chuck and I've ordered another. If I read the reviews right, the problem I have happens from time to time. The majority of people with these chucks report that they work fine. Fingers crossed for the next one.

BTW, mine came with a threaded backing plate. I didn't intend to use it but it was a big free piece of metal. It is threaded 1-1/2 x 8 even though the listing title says "2-1/4 x 8". Glad I wasn't depending on that!

Craig

Am@zon kept showing me 5C collet chucks at lower and lower prices until I finally took a flyer. "Findmall" brand. It arrived in 2 days (no Prime) and it looked good. Super smooth ground finish and virtually impossible to see the line between the upper and lower halves of the body.

I took it apart and there was some fine swarf that fell out. The usual filthy brown 'grease'. The parts looked good on the inside though too. The pinions and ring gear that tighten a collet into the chuck *look* fine.

After cleaning, lubricating and reassembling the parts, the trouble started. The chuck would turn freely _until_ I tried to tighten a collet. I had to press the collet into the chuck a little to get it to start threading. Within a few turns, it would get very hard to turn the T-handle. Then it would free up and turn easily for a couple of turns of the handle. Eventually it would get too hard to turn--before the collet was fully engaged in the taper.

I havent measured to verify but I believe the threaded hole in the ring gear is slightly eccentric. As the collet is drawn in, the tolerances stack up so the collet binds against the front body of the chuck. Note that the ring gear rotates smoothly as long as no collet is engaged. Also, I verified that a collet will easily thread into the ring gear while disassembled.

So I'm returning this chuck and I've ordered another. If I read the reviews right, the problem I have happens from time to time. The majority of people with these chucks report that they work fine. Fingers crossed for the next one.

BTW, mine came with a threaded backing plate. I didn't intend to use it but it was a big free piece of metal. It is threaded 1-1/2 x 8 even though the listing title says "2-1/4 x 8". Glad I wasn't depending on that!

Craig