-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Converting Mini Mill to CNC

- Thread starter Alexander

- Start date

I've sold the mill to @kevin.decelles. Hope you don't mind me saying so Kevin. He's tinkering away... hope he posts soon.

Awesome. That's the big brother to mine. I'm almost done converting to CNC. Lucky to have paid so little for it. I bought mine new.I paid $260 for everything. I was looking more at them today they are actually 890ozin. I feel like I got a good deal. This system would cost 3 times that right now. Plus it is all wired up and running. Hmm now I have lots of work to do. This is the mill I have. So much for building a mini cnc that I can bring to maker fair.

View attachment 519

John

@kevin.decelles let's see some pics!

So mine is the HoT equiv. to the Grizzly G3616. A friend here on the island has the HoT G3617 with the horizontal mill attachment. His table is longer and the head is longer than mine. It looks like the one Kevin has is the same size as mine but with the horizontal mill.

I made castings for all the end plates to be able to hold angular contact bearings. I started with DC Servos running with HP_UHU drives and US Digital Encoders. Ultimately the short story is that although the XY servo motors were supposed to be identical, they weren't. So now I've replaced them with Bergerda AC Servos. Very happy with that. They are 400W units with the same torque as the DC Servos. 3:1 on X, 4:1 on Y

I started with a 600 oz-stepper on the knee and 3:1 reduction. Upped that to 960 oz-in and a Gecko. The Gecko failed and I tried a Leadshine driver from amazon. That had a horrible whine when stopped so I finally switched over to a Bergerda 750W AC Servo. Now instead of max 24 ipm on the knee I can get 150 ipm. Scary fast.

The quill is locked at the top unless I'm doing things manually.

I have tons of pictures and can take more. Just ask for specific areas. Here is a random sampling. I replaced the bushing at the Z axis bevel gear end with a ball bearing too. There is still too much play there.

I made castings for all the end plates to be able to hold angular contact bearings. I started with DC Servos running with HP_UHU drives and US Digital Encoders. Ultimately the short story is that although the XY servo motors were supposed to be identical, they weren't. So now I've replaced them with Bergerda AC Servos. Very happy with that. They are 400W units with the same torque as the DC Servos. 3:1 on X, 4:1 on Y

I started with a 600 oz-stepper on the knee and 3:1 reduction. Upped that to 960 oz-in and a Gecko. The Gecko failed and I tried a Leadshine driver from amazon. That had a horrible whine when stopped so I finally switched over to a Bergerda 750W AC Servo. Now instead of max 24 ipm on the knee I can get 150 ipm. Scary fast.

The quill is locked at the top unless I'm doing things manually.

I have tons of pictures and can take more. Just ask for specific areas. Here is a random sampling. I replaced the bushing at the Z axis bevel gear end with a ball bearing too. There is still too much play there.

Attachments

Former Member

Guest

Just doing a cnc conversion to my Craftex knee mill, using the Acorn cnc board and Clearpath Nema 34 servo's, direct drive. Motor has been converted to VFD, and just installed a rotor encoder to measure RPM accurately. Post some pic's when I'm done. Now I just have to learn g-code.

Good project! I have an acorn based lathe. Will your rotor encoder support rigid tapping? Eg multiple passes to do threading?Just doing a cnc conversion to my Craftex knee mill, using the Acorn cnc board and Clearpath Nema 34 servo's, direct drive. Motor has been converted to VFD, and just installed a rotor encoder to measure RPM accurately. Post some pic's when I'm done. Now I just have to learn g-code.

Former Member

Guest

It should, basically I used the OMRON E6B2-CWZ1X 2000p/r Rotary Encoder. The Positional count per Rev is about 32000 because I am taking the feed off largest of the pulley on the spindle via a contact wheel. I'll post a pic when I get a chance to take it (some initial fine calibration is required.Good project! I have an acorn based lathe. Will your rotor encoder support rigid tapping? Eg multiple passes to do threading?

May I ask why you chose Acorn over say a MESA Solution and LinuxCNC running on a PC or Pi4. Granted Pi4 4GB is hard to find at the moment but PCs can be had for next to nothing as well as LinuxCNC is free.

Former Member

Guest

Did my research, liked that it was Windows compatible (sorry been at computers too long and don't need to learn another set of headaches). Additionally it is plug and play using the add on board from CNC4PC for the Clearpath SDSK. Clearpath was to only choice based on the torque and built in encoding and processing. Based on the basic encoder 0.000125 is possible if all works as designed and the winds in the right direction.

link for this? casually searching sees them for $250+ on amazon?It should, basically I used the OMRON E6B2-CWZ1X 2000p/r Rotary Encoder. The Positional count per Rev is about 32000 because I am taking the feed off largest of the pulley on the spindle via a contact wheel. I'll post a pic when I get a chance to take it (some initial fine calibration is required.

https://www.ebay.ca/itm/31256611274...55-0&campid=5338722076&customid=&toolid=10050

on ebay it's $45 but I assume it's a chinese counterfeit.

on digikey.ca they are $1000-1500 ! The amazon one must also be counterfeit.

Last edited:

I picked acorn because of the software CNC 12 which appeared to be good. So far I like it but the HAAS NGC is better.Did my research, liked that it was Windows compatible (sorry been at computers too long and don't need to learn another set of headaches). Additionally it is plug and play using the add on board from CNC4PC for the Clearpath SDSK. Clearpath was to only choice based on the torque and built in encoding and processing. Based on the basic encoder 0.000125 is possible if all works as designed and the winds in the right direction.

Former Member

Guest

Yes Ebay is where got it. Seem to function fine (I suspect its the actual manufacturer), the bigger is the contact wheel that is giving me a headache at higher speeds.link for this? casually searching sees them for $250+ on amazon?

https://www.ebay.ca/itm/31256611274...55-0&campid=5338722076&customid=&toolid=10050

on ebay it's $45 but I assume it's a chinese counterfeit.

on digikey.ca they are $1000-1500 ! The amazon one must also be counterfeit.

I'll get you give me a g-code lesson.

Former Member

Guest

Former Member

Guest

Done some tests with the encoder and it works extremely well, except for the contact wheel, because of the takeoff point the RPM's on the encoder can exceed 12,000RPM yes that is correct, the encoder handles it the silcone wheel starts to expand and and slip on the wheel.

New idea that should work, getting it closer to a one to one ratio, but I need to do some welding and construction for this along with cutting a hole in the cover (maybe just remove the cover complete and build a new safety shroud.

New idea that should work, getting it closer to a one to one ratio, but I need to do some welding and construction for this along with cutting a hole in the cover (maybe just remove the cover complete and build a new safety shroud.

Former Member

Guest

Little further update, Pulley for the quil is going to get a take of point mounted on top of it out of 1" thick AL machined (turned to size) and drilled to allow access for the drawbar. Cover/belt gaurd will be removed and changed.

I'l post some befoe and after pics.

I'l post some befoe and after pics.

Former Member

Guest

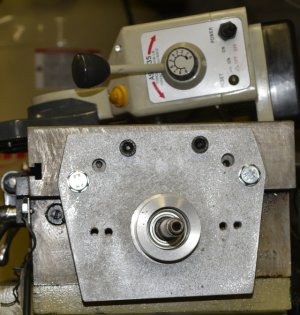

Here are some pic's as promised.

The Original mount and take-off and now you can see why the encoder could be spin beyond 12,000 RPM. The Silcone wheel didn't like it. Who knew 🙄.

And here is the new take-off point giving a close to 1:1 ratio. Fine tuning on CNC12 will be done with a tach on the spindle (I have an electronic one from my earlier days).

Still have to rebuild the Encoder mount to bring it in contact with the takeoff point. Now at max the it will be less than 4,000 PRM (Closer to 3800 maximum spindle speed of at 100Hz on the VFD).

The Original mount and take-off and now you can see why the encoder could be spin beyond 12,000 RPM. The Silcone wheel didn't like it. Who knew 🙄.

And here is the new take-off point giving a close to 1:1 ratio. Fine tuning on CNC12 will be done with a tach on the spindle (I have an electronic one from my earlier days).

Still have to rebuild the Encoder mount to bring it in contact with the takeoff point. Now at max the it will be less than 4,000 PRM (Closer to 3800 maximum spindle speed of at 100Hz on the VFD).

Interesting way of getting an encoder onto the spindle. Hadn't thought of that approach. I went a different way. Since I'd upgraded to a step/dir AC Servo which was the same prices as upgrading to a 3phase motor and quality VFD I knew I'd probably not need all 8 or 9 belt positions.

I thought about just cutting slots in the largest spindle pulley at the bottom but then my head went into the area of what if it doesn't work or you screw it up. No replacements available for this mill anymore. So instead, since I had to fit a custom pulley on the motor because shaft size was too small on the original why not make a new spindle pulley too? One with only room for two belt positions.

Then experiment with a 3D printed mount that I'd eventually swap with metal.

I used two of the exiting head bolts as mounts and created special bolts to replace the existing ones after I broke a tap in the original bolt.

Now I can do power tapping with LinuxCNC. The sensors were bought over 10 years ago before China flooded the market with the inexpensive OMRON clones. Which I couldn't see using because the cone drive diameter is so large I'd need a corresponding large one on the encoder and no easy way of making that belt driven pulley.

I thought about just cutting slots in the largest spindle pulley at the bottom but then my head went into the area of what if it doesn't work or you screw it up. No replacements available for this mill anymore. So instead, since I had to fit a custom pulley on the motor because shaft size was too small on the original why not make a new spindle pulley too? One with only room for two belt positions.

Then experiment with a 3D printed mount that I'd eventually swap with metal.

I used two of the exiting head bolts as mounts and created special bolts to replace the existing ones after I broke a tap in the original bolt.

Now I can do power tapping with LinuxCNC. The sensors were bought over 10 years ago before China flooded the market with the inexpensive OMRON clones. Which I couldn't see using because the cone drive diameter is so large I'd need a corresponding large one on the encoder and no easy way of making that belt driven pulley.

Former Member

Guest

That take off wheel started as a piece of 5-3/4 x 5-3/4 x1" thick Al 6061 plate. Little bit of Drill press work, little bit of lathe work, some bandsaw to reduce lathe work, more lathe, finally a little more drill press (1-1/2 later) mounted. BTW the take off is friction fit and the encoding is going to work out to about 8000 per revolution. In the original set up it was closer to 33,000.

Although you can't see it in the photo, the casting of the head frame didn't allow me to put anything above the pulley. Mine is running 60 pulses per rev IIRC plus the index of course. I've been able to do power tapping with that. The other day I ran it 6 RPM to ream some 3D printed PLA and not melt it while reaming.That take off wheel started as a piece of 5-3/4 x 5-3/4 x1" thick Al 6061 plate. Little bit of Drill press work, little bit of lathe work, some bandsaw to reduce lathe work, more lathe, finally a little more drill press (1-1/2 later) mounted. BTW the take off is friction fit and the encoding is going to work out to about 8000 per revolution. In the original set up it was closer to 33,000.