They are both fast and accurate but the material has to be on size (to no more than +- 0.001" - with the 3C, 5C, R8 types) to not distort them when clamping stock.

There are prolly more than a few who disagree, but my experience backed by advice from several collet makers is more forgiving. My 5C chuck gets used more than all the others combined. My experience works for me and gets great results. But it's still just my opinion.

I find that 0 to -10 thou is usually good enough on the bigger collets. 10 thou is really only 5 thou per side. Smaller collets can sometimes need to be a bit tighter. On the really small ones I might shoot for 0 to -3 thou. I really don't think plus (+) anything is a good idea (despite thousands of web quotes to the contrary). Careful inspection of the collet fingers suggests that most collets don't handle expanding really well because it distorts the root of the gripping finger faces in a way that concentrates the forces and can damage the collet and potentially the collet holder. If the work doesn't slide freely into the collet, I use the next size up. I never force work into a collet.

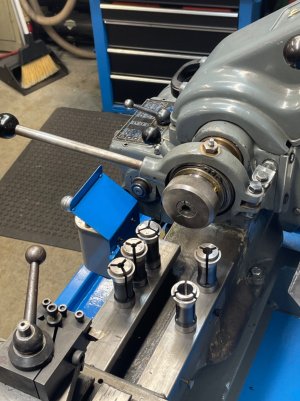

5C collets are widely available in 1/64 increments, and you can get 1/128ths. You can also get custom sizes if you open your wallet enough. 1/64 is close enough to 15 thou (7 on a side). 128th is 8 thou (4 thou on a side). But a full set of 64ths or worse 128ths is just too much coin. Keeping in mind that 5C is primarily designed to hold stock, exact fits are rare. According to most of the manufactures, -8 thou won't hurt them. But it might not grip as tightly as desired. Therefore I often use shims.

A pop can wall is usually around 3 to 4 thou. So I like to use a wrap (or two) of a pop can wall (slightly wider than the grip length of the collet) as a shim to get a tighter fit on my 32nds collets when needed.

Never even once has a 5C collet of mine ever let go - even on the heaviest cuts I have taken. I have broken a few tools though.

Thats my experience for whatever it is worth, and that's my advice to others. Get a good set of 32nds and use pop can shims as necessary to get a good fit.