PTFE, Acetal (POM-C), Delrin (POM-H)...all terrific material and I am always impressed with how well they work. Great fun to machine as well.you caught those in the nick of time before it wore into the casting.

that should last a very long time. The key will be to keep the feed rod clean as any hard particles will easily embed in the soft PTFE and abrade the shaft quickly.

i make it a habit of turning off the feed system when not in use

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Colchester Student 13"

- Thread starter ScottyM

- Start date

Brent H

Ultra Member

Hey ScottyM,

My Utilathe is the 10x20 model. Not sure of the year of manufacture : Serial number is U530.....sounds like a WWII U-Boat - LOL I have a write up on this forum about the work to restore it and making parts. Currently finishing off the taper attachment when I get home and will be making some gears for the apron when I get a few things made up for the mill and gear cutting.

I would guess its somewhere late 60's or so as there is some carry over with the 11" series 2000 with respect to the cross feed and having wedge type gibs instead of flat set screw type. If you ever come across any parts for the beast let me know! I will be trying to make up a metric set of change gears as well.....

My Utilathe is the 10x20 model. Not sure of the year of manufacture : Serial number is U530.....sounds like a WWII U-Boat - LOL I have a write up on this forum about the work to restore it and making parts. Currently finishing off the taper attachment when I get home and will be making some gears for the apron when I get a few things made up for the mill and gear cutting.

I would guess its somewhere late 60's or so as there is some carry over with the 11" series 2000 with respect to the cross feed and having wedge type gibs instead of flat set screw type. If you ever come across any parts for the beast let me know! I will be trying to make up a metric set of change gears as well.....

@RobinHood

Right! Haha just measured them actually, only 11.5 thou left before it would have started into the casting!

I also never run feeds system if not using, one less thing to get your fingers wrapped around and less wear. I'm tempted to make a 2-piece bushing, inner bush keyed to the shaft so it rotates with and its not using the shaft as a bearing surface. With the amount of wear there was it clear there's room for improvement.

@CalgaryPT

Soooo satisfying to machine, the sound it makes as you zing through it is what dreams are made of.

Right! Haha just measured them actually, only 11.5 thou left before it would have started into the casting!

I also never run feeds system if not using, one less thing to get your fingers wrapped around and less wear. I'm tempted to make a 2-piece bushing, inner bush keyed to the shaft so it rotates with and its not using the shaft as a bearing surface. With the amount of wear there was it clear there's room for improvement.

@CalgaryPT

Soooo satisfying to machine, the sound it makes as you zing through it is what dreams are made of.

Brent H

Ultra Member

Holy smokes! Colour that bushing gone! wow - great timing. Might work well if the bearing bronze you used for a replacement was oil impregnated and a harder high load type?

If it is the feed drive, any possibility of converting to a roller bearing assembly? If the housing is long enough you could use a ball bearing suitable to absorb axial loads in both directions - would cancel out the shaft wearing on another surface?

If it is the feed drive, any possibility of converting to a roller bearing assembly? If the housing is long enough you could use a ball bearing suitable to absorb axial loads in both directions - would cancel out the shaft wearing on another surface?

It's -30 where I'm at today so decided it was a good afternoon for some shop time.

I wanted to clean up the steady and follow rests. These are in great shape other than the grime and flaking paint. I am itching to start painting but must be patient, why do all the good paints have to be so bad for you?

Disassembly went smooth, one thing to note is there are little copper balls under the set screws to lock the fingers in place. I didn't notice at first and almost lost them. When I get another mill I'd like to slot the fingers and turn down the ends of the set screws to index the slots. This would also give a flat bottom contact for securing with the set screw, I don't like the point contact of the balls for this. When slotted I can make some caps with ball bearings.

Went through and took off any high spots and burrs after a good clean. This stuff was hard on the finger tips, but all worth it seeing the end result.

I wanted to clean up the steady and follow rests. These are in great shape other than the grime and flaking paint. I am itching to start painting but must be patient, why do all the good paints have to be so bad for you?

Disassembly went smooth, one thing to note is there are little copper balls under the set screws to lock the fingers in place. I didn't notice at first and almost lost them. When I get another mill I'd like to slot the fingers and turn down the ends of the set screws to index the slots. This would also give a flat bottom contact for securing with the set screw, I don't like the point contact of the balls for this. When slotted I can make some caps with ball bearings.

Went through and took off any high spots and burrs after a good clean. This stuff was hard on the finger tips, but all worth it seeing the end result.

Holy smokes! Colour that bushing gone! wow - great timing. Might work well if the bearing bronze you used for a replacement was oil impregnated and a harder high load type?

If it is the feed drive, any possibility of converting to a roller bearing assembly? If the housing is long enough you could use a ball bearing suitable to absorb axial loads in both directions - would cancel out the shaft wearing on another surface?

That's also another option I'm considering. The bushings have a wall thickness of 1/8" and not enough meat to bore the casting any larger, needle rollers are a no go. I do have plenty of room on either side to mount ball bearings on the outside of the worm box. Really I think the bushings are undersized for the load they see.

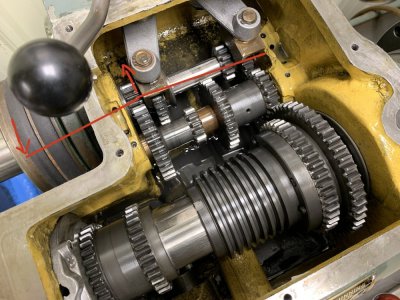

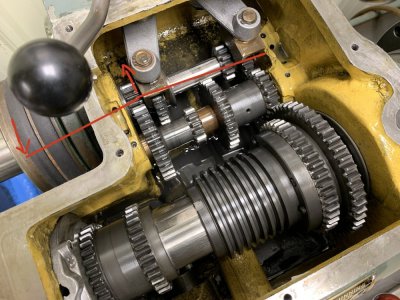

I'm not sure if I am looking at the equivalent part to my 14x40 powerfeed drive line. Did you check for wear on the casting adjacent to worm gear? (red arrow).

Mine was a crappy setup to begin with, but the worm gear is capable of wearing out the cast iron bracket. I tossed the cast iron bracket, made new blocks & installed mirrored bronze bushings on either side so it has something sacrificial to bear on power feeding in or out.

Mine was a crappy setup to begin with, but the worm gear is capable of wearing out the cast iron bracket. I tossed the cast iron bracket, made new blocks & installed mirrored bronze bushings on either side so it has something sacrificial to bear on power feeding in or out.

Attachments

RobinHood

Ultra Member

You probably already know this, on the newer Mark2 models they seem to have improved the apron feed bushing.

here is a video of a fellow working on a 1964 Mark2. You can see the much beefier bushes starting at about 0:30.

perhaps you could model your future Improvements after the factory upgrades

here is a video of a fellow working on a 1964 Mark2. You can see the much beefier bushes starting at about 0:30.

perhaps you could model your future Improvements after the factory upgrades

@PeterT - Luckily no wear in that section! Shaft had a great fit in the casting and very little side to side play on the worm/gear combo. You can see in the pictures of the bare casting that the surface isn't eaten away at all - lots of bearing area on the side of the worm and not too much pressure due to the gear reduction I'd say.

@RobinHood - I hadn't looked closely at the mk2 apron but seems like a much better design all around, not to say that the mk1 is bad by any means. Might be able to take some inspiration from it! What Colchester are you running? I was reading through your taper attachment build and tried to find what specific model with no luck.

@RobinHood - I hadn't looked closely at the mk2 apron but seems like a much better design all around, not to say that the mk1 is bad by any means. Might be able to take some inspiration from it! What Colchester are you running? I was reading through your taper attachment build and tried to find what specific model with no luck.

RobinHood

Ultra Member

What Colchester are you running? I was reading through your taper attachment build and tried to find what specific model with no luck.

its a Colchester Master 2500. It had a lot of rust on it and the spindle was “seized”. Not really seized, just someone managed to get it into two gears at the same time and they were not able to get it going again.

It required the whole headstock gearbox to be disassembled because the shift forks are at the very bottom of the HS (all the nested gears and the shafts had to come out) in order to free the thing up.

While I was in there, I just replaced all the bearings (except the spindle bearings - they were in excellent shape), repaired the clutch fork, improved the lubrication system (it has a ”dry sump“ system with no oil bath in the headstock but rather an external tank and pump), improved a gear shift fork for better gear mesh and replaced a worn bushing (caused by the bad factory gear mesh - a weakness on the Master).

It runs really nice now. I did make a all of the missing parts in the taper attachment as well (You saw that).

Now I just need to make a 56T change gear (to give me the full range of 39 Metric threads, 45 SAE threads, 18 Module and 21 DP threads ((with other gears, even more threads can be cut))); a steady and a follow rest (unless I can find them reasonably priced - which at the moment does not seem possible...)

link to clutch fork repair: https://canadianhobbymetalworkers.com/threads/clutch-fork.1185/

link to shaft repair and gear bushing replacement: https://canadianhobbymetalworkers.c...-and-gear-bushing-replacment.1186/#post-11760

@RobinHood - Awesome stuff! I will be replacing the equivalent bushing on mine. Looking inside the headstock and at gear stack up from the manual I don't have the same hardened retaining clips, just one long bushing. Hopefully won't run into the same scoring issues on the shaft.

On a side note, how do you go about getting the smaller pictures on your write ups until clicked? I'm not too fond of how mine have been showing full size, text gets lost in my opinion.

On a side note, how do you go about getting the smaller pictures on your write ups until clicked? I'm not too fond of how mine have been showing full size, text gets lost in my opinion.

Last edited:

RobinHood

Ultra Member

On a side note, how do you go about getting the smaller pictures on your write ups until clicked? I'm not too fond of how mine have been showing full size, text gets lost in my opinion

once you upload your picture, you should see two choices after “insert” in inverse video: one is ”Thumbnail” the other is “Full image”. I use Thumbnail for the most part.

here is a sample of a Thumbnail

RobinHood

Ultra Member

I wanted to attach the manual I made up for the Utilathe but it didn't work.

there might be a file size restriction or some other constraint that prevents you from uploading the file.

i am sure one of the Admin wizards will chime in and be able to help out...

Bad news! I have some shafts and bushings to make...

As mentioned previously, there was some play in the input shaft and and second shaft (what I was previously calling the idler shaft). I was hoping the bushings were just worn and the shafts would be good, but also knew better.

Right off the bat, I found the cause during the teardown. When going to take off the belts and pulley's it was clear that the belts were way too tight. Like wayyyy too tight. This jacked the shaft and caused the fluid film for the bushings to disappear at the pressure points. This wasn't helped by the input shaft being two pieces, the shorter sections allowing more movement and less resistance to the moment on the shaft. This only got worse as the shafts/bearings wore. The pictures below try to show the play in the pulley and the split input shaft.

I cut the belts since they needed replacing anyway. Pulleys came off and showed the braking mechanism, good news here is that there is lots of meat left on the pads, that would have been a pain to replace. Off came the mechanism and bushing housing. The input shafts, secondary shaft, associated gears and bushings quickly followed.

And here they are, there was lots of bearing material and sludge in the bottom of the head after draining the oil. This sludge also coated everything else. You can see the heavy wear/grooving on the shafts, and the uneven wear on the shafts that were jacked due to the excessive belt tension. What's funny is some of the bushings pressed into the gears are still perfectly on size, they got embedded with the sludge and wore the shaft instead. I also suspect some of these bushings were replaced at some point without anything being done to rectify the shafts. Recipe for recurring failure.

The good news? There were no big chunks loose in the head and all the gears are still in great shape!

Looks like it's time to start making. But hey, I love to buy all this machining equipment and make parts. What am I supposed to do? Act mad now that I have to do it? Bronze has been ordered and I am chomping at the bit to get started!

As mentioned previously, there was some play in the input shaft and and second shaft (what I was previously calling the idler shaft). I was hoping the bushings were just worn and the shafts would be good, but also knew better.

Right off the bat, I found the cause during the teardown. When going to take off the belts and pulley's it was clear that the belts were way too tight. Like wayyyy too tight. This jacked the shaft and caused the fluid film for the bushings to disappear at the pressure points. This wasn't helped by the input shaft being two pieces, the shorter sections allowing more movement and less resistance to the moment on the shaft. This only got worse as the shafts/bearings wore. The pictures below try to show the play in the pulley and the split input shaft.

I cut the belts since they needed replacing anyway. Pulleys came off and showed the braking mechanism, good news here is that there is lots of meat left on the pads, that would have been a pain to replace. Off came the mechanism and bushing housing. The input shafts, secondary shaft, associated gears and bushings quickly followed.

And here they are, there was lots of bearing material and sludge in the bottom of the head after draining the oil. This sludge also coated everything else. You can see the heavy wear/grooving on the shafts, and the uneven wear on the shafts that were jacked due to the excessive belt tension. What's funny is some of the bushings pressed into the gears are still perfectly on size, they got embedded with the sludge and wore the shaft instead. I also suspect some of these bushings were replaced at some point without anything being done to rectify the shafts. Recipe for recurring failure.

The good news? There were no big chunks loose in the head and all the gears are still in great shape!

Looks like it's time to start making. But hey, I love to buy all this machining equipment and make parts. What am I supposed to do? Act mad now that I have to do it? Bronze has been ordered and I am chomping at the bit to get started!

Another approach is to turn and polish the shafts to concentric by taking minimal material, then making extra thick bushings to accommodate. Saves a lot of work making new shafts, and for light (hobby) use, ti should suffice. You can always make new shafts later and re-bore the bushings.

@Hruul - Apologize I missed your post last time, I picked it up in eastern Saskatchewan after finding on kijiji.

@PeterT - Thanks Peter, I'm glad you're enjoying it! I have a lot of 4140 and some W2 tool steel that are both great choices. Both are very tough and heat treat beautifully. I will either case harden so the bearing area is very hard while still preserving the toughness from a softer inner shaft, or through-harden and temper back. Both would work but I'm leaning towards through hardening as this is a smaller shaft and I want to limit the deflection that originally caused this damage.

The gear on that shaft is integral, that one has the least wear and simple features so I will most likely grind out the wear and just make it up in the bushings. Also thick enough to not worry about preserving material. If for whatever reason I do have to make a new shaft, I'll part off the gear with an inch or so of the shaft left, turn it down to a smaller diameter and press into a recess on the replacement. Pin through for good measure.

@Dabbler @WilliamG - I have always wanted to try spray buildup but don't know anyone with the equipment, looks like a lot of fun. That and the thicker bushings are both great options. I should have worded my post differently. I have yet to take good measurements of the wear on the shafts as I went straight to removing the spindle after that. Depending on what kind of wear I'm dealing with I'll pick whatever fix will work the best for each.

These are the options I'll pick from:

- Turn/Grind down worn area and replace with hardened sleeve

- Turn/Grind down worn area and make up difference in bushing

- Build shaft back up with TIG and turn/grind back to size (controlled preheat and cool down to prevent warp)

- Build new

@PeterT - Thanks Peter, I'm glad you're enjoying it! I have a lot of 4140 and some W2 tool steel that are both great choices. Both are very tough and heat treat beautifully. I will either case harden so the bearing area is very hard while still preserving the toughness from a softer inner shaft, or through-harden and temper back. Both would work but I'm leaning towards through hardening as this is a smaller shaft and I want to limit the deflection that originally caused this damage.

The gear on that shaft is integral, that one has the least wear and simple features so I will most likely grind out the wear and just make it up in the bushings. Also thick enough to not worry about preserving material. If for whatever reason I do have to make a new shaft, I'll part off the gear with an inch or so of the shaft left, turn it down to a smaller diameter and press into a recess on the replacement. Pin through for good measure.

@Dabbler @WilliamG - I have always wanted to try spray buildup but don't know anyone with the equipment, looks like a lot of fun. That and the thicker bushings are both great options. I should have worded my post differently. I have yet to take good measurements of the wear on the shafts as I went straight to removing the spindle after that. Depending on what kind of wear I'm dealing with I'll pick whatever fix will work the best for each.

These are the options I'll pick from:

- Turn/Grind down worn area and replace with hardened sleeve

- Turn/Grind down worn area and make up difference in bushing

- Build shaft back up with TIG and turn/grind back to size (controlled preheat and cool down to prevent warp)

- Build new

Last edited: