GerryinBelleRiver

Well-Known Member

I purchased this mill in the summer of 2019 after looking for one for close to 2 years. Although it was cosmetically challenged it was a fairly tight machine and came with a load of tooling.

As I needed to complete a number of machine restorations I put it into immediate service with the intent on tackling a total refresh; clean , paint, shine at a later date.

While the time has come and I spent the morning doing a complete tear down. Ended up with quite the pile of parts. This may take a while.

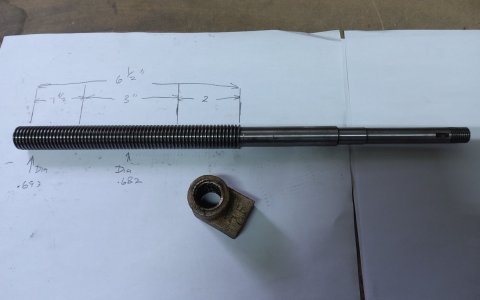

I did discover enough wear on the lead screw for the y axis to justify replacing it and the bronze nut. It currently has about 12 thou of backlash. If I can not find new ones I may have to make them which might be difficult without the use of a mill. Worst case I will put it back together, make what I need and replace the parts. Will make some accurate drawing of original parts just in case.

Also noted some small gouges on one of the ways but I don't think they will really effect the accuracy of the mill. While I am at it I will probably put a DRO on the mill.

Anyway, trying not to turn a simple refresh into a full fledged restoration. Wish me luck.

As I needed to complete a number of machine restorations I put it into immediate service with the intent on tackling a total refresh; clean , paint, shine at a later date.

While the time has come and I spent the morning doing a complete tear down. Ended up with quite the pile of parts. This may take a while.

I did discover enough wear on the lead screw for the y axis to justify replacing it and the bronze nut. It currently has about 12 thou of backlash. If I can not find new ones I may have to make them which might be difficult without the use of a mill. Worst case I will put it back together, make what I need and replace the parts. Will make some accurate drawing of original parts just in case.

Also noted some small gouges on one of the ways but I don't think they will really effect the accuracy of the mill. While I am at it I will probably put a DRO on the mill.

Anyway, trying not to turn a simple refresh into a full fledged restoration. Wish me luck.