Canadium

Ian

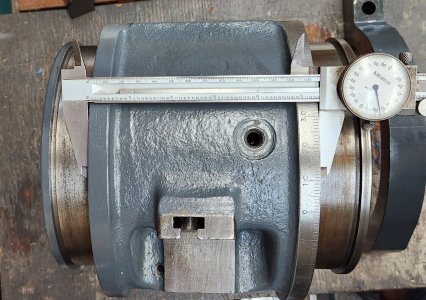

That looks almost identical to the problem I had with my dividing head! In my case there were plenty of hammer marks on the outside of the cradle which I surmised told the whole story of how this came to be. I concluded forcing it back together would probably cause some thing to break and any way I wanted the thing to rotate in the cradle like its supposed to.. So I carefully removed metal until I got the desired result.