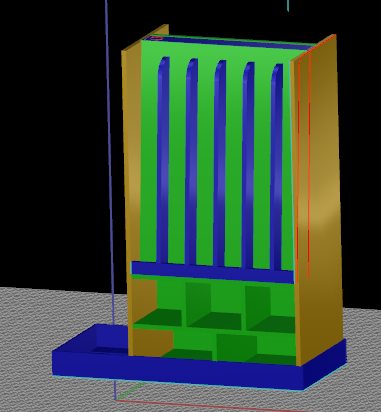

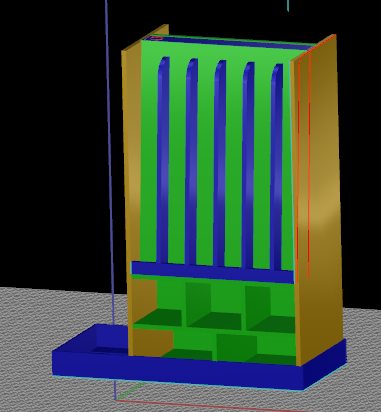

Here's the stock rack at the moment. I still have a few things I want to change around, and details to be modeled, but the bones are there. Once finished I'm going to send it out to be routed from prefinished ply, so assembly is quicker on my end. Just glue and screw it together. None of my woodworking tools are really setup and usable right now, and as much as I'd love to take this on (I miss doing this kind of stuff), I've got nowhere to work on such a large carcass right now. Nor the time to do so. I thought about making it from steel, and do have somewhat of a similar design from tubing/angle, but it would use up almost all the steel I have that I wish to store, so.....a bit of a catch 22 lol. Base is 4x4 angle (I have a bunch....) @ 20"x42" and it's made to fit in a certain spot in my garage.

The bases I plan on making for the machines will be solid, and not affect rigidity. Just more pallet jack friendly, not actual pallets. The excello one will be just a heavy 4"x4"x3/8" angle iron cradle the base sits in with big leveling feet on the corners that I can zip up with the impact to get the jack underneath. Simple and wont affect rigidity, would actually increase the footprint size, and will add the ability to level it which is needed on my floor.... My little Myford has a fabricated base already, the previous owner built it, it's just not very moving friendly. Whenever I need to move it, I have to slip some beams in there to catch on the crossmembers in the bottom. I've got the song down now, and can dance it around the shop wherever I want to put it, but I don't really like the stand as a whole, and a new one has been on the list ever since I got it.

Welding table will get a completely new enclosed base with integral toolbox/welding supply storage, that I can slip the jack under from any side and move it around. A fabrication station I can wheel out into the driveway when the weather is nice. I hate welding and grinding in the shop, but it seems like it's all I've done in there this year.

The forks on my tractor have been one of the handier things I've made. I bought some forklift forks, and built a frame to go on the 3pth about 10 years ago now, and the ROI has been phenomenal. Now if I could only get the tractor running again......Governor issues again, and I haven't found the time, and motivation to dig into it. I think it's time to put the old girl (1963 Mf35 conti gas) to pasture and buy a new(er) one. Waiting for the covid prices to come down (which they are), and pickup something from the 70's, maybe 80's (I'm a cheap sucker for punishment.....) diesel, with a good loader and strong hydraulics with remotes for under 10k.

`