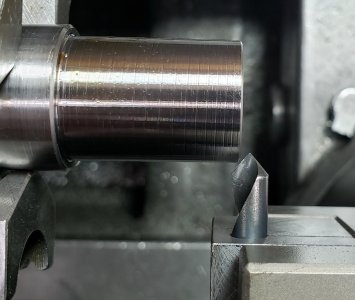

Whenever I turn on the lathe, I want a chamfer on the edges. More often than not, its just to remove the sharp edge. I've tried the standard chamfering tools, but they always still seem to leave a burr. I invariably just pick up a file and deburr the outside, or a triangular scraper and do the internal, which is not the safest of operations. I decided to dedicate a QCTP holder to use a home made split block which holds a 1/4" singleflute on both ends. Well, lo and behold, it seems to work, without leaving any burrs. The cutters I'm using were just to experiment with. I will order 2 1/4" single flute 90° countersinks.

Now if I had one of those D-bit/single lip grinders, you would only need to make a single piece at 90° that would do both external and internal chamfer.

Now if I had one of those D-bit/single lip grinders, you would only need to make a single piece at 90° that would do both external and internal chamfer.