What @trevj said.I used to hang with a couple old farts that were heavily in to casting, and maybe their site info is still to be got by searching.

The two Names were Robert (Bob) Grauman, and Rupert Wenig. Both now lost to us, sadly.

Robert was pretty involved with the various back alley (essentially) casting shops that operated around Edmonton, and Rupert was from between Camrose and Edmonton Alberta.

Rupert was casting Iron, with a naturally aspirated furnace, and green sand, and Robert left me his, essentially, entire library of books! Plus some other stuff...

I learned the following from them.

First, There are two types of Bentonite. Western, and Southern. One makes things stick, the other is slimy when wet. IIRC, cat litter, is the wrong kind of Bentonite (Western, IIRC, and is also used a lot as drillers mud in the oil industry. I am pretty sure it was Southern Bentonite you wanted for green sand. According to http://www.ece.ualberta.ca/~wyard/foundry/designlog.html I am correct.

You can cast about anything in green sand, you only need to sift it through, to remove any inclusions, and get the moisture level right, and you are in business. Green sand is about your only choice if you want to cast Iron.

Petrobond pretty much NEEDS a Muller, a device that presses and mashes the oil on to the sand. Think, rotating bowl, with big wide wheels, rolling over the sand mix. A fluffer helps (no, not that kind!) basically a powered unit to break all the burnt bits to small enough pieces that the muller can handle. I have seen several, including Rupert's that were a upside down salad bowl with a bunch of bolts set through it facing up, so as to whir around and break up the bits, as they were fed through a hole over the center of the fluffer. Hard to describe. Dump sand in top, it comes out busted up, around the edges of said bowl. Usually a batch of petrobond has a couple casting cycles before it 'needs' to be mulled. YMMV! When you are really on point, is when you see your own fingerprints transferred to the casting, from the pattern! Petrobond, with fine sand, can take up details well beyond what you would expect.

While I have seen writings suggesting using any old oil to make petrobond, I had been told, that there is a special oil made for the purpose. Sorry, cannot name names, as I don't have them to hand.

I have a fluffer like the one Rupert had. I don't know what happened to the muller he acquired.

I use it to break the hard dry stuff down. I bought my bags of casting sand a few decades ago as a premix. It was a bit coarser than I might have liked but overall it's been pretty good. If I haven't used it for a while I use a watering can, add some water, shovel it around, lay plastic on top and some thing to hold it down. Then put the cover back on the tote box.

After a few days the moisture has basically stabilized and then using the fluffer I can mix it all around and cast.

BTW, just as a point of remembering. Rupert Wenig was just outside of Camrose. His shop burnt down due to a grass fire. He rebuilt and continued with casting and machining. His CNC router table was a work of art. The Gingery Horizontal Mill would have been too had it not been melted in the fire.

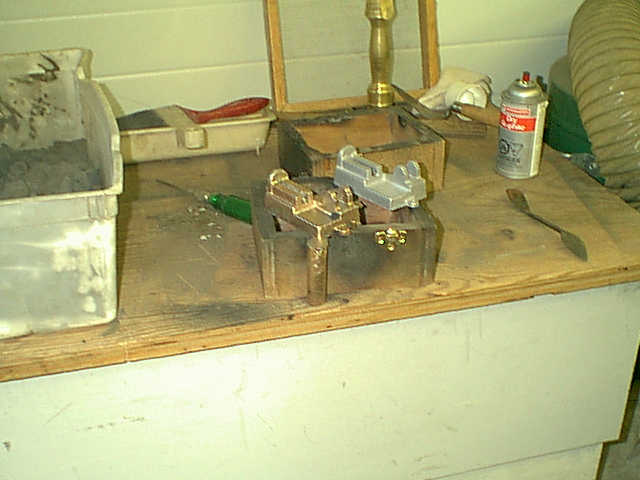

This photo is from 2003.