I picked up this drill press for a little winter project, its the same as this buffalo Junior but the casting shows Canadian Blower and forge co. and the front label shows The Canadian Fairbanks Morse Co Ltd so I guess it was the same as the buffalo but made here in Canada. Everything moves, the motor is very quiet and smooth, they were had a strap from a tie down as a belt so needles to say that doesn't work well, luckily I have some belting I believe will work, the quill moves nicely as does the table and swivel My hope is to clean it up referb it a bit and use it for doing the odd holes maybe find a corner for it.

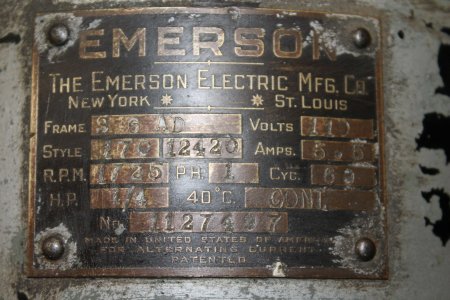

These look like just oil soaked felt wadded up inside very cool snap lids very cool old emerson moter.

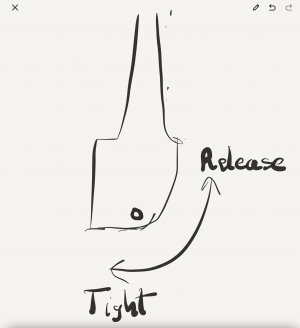

Edit I am adding the picture from the vintage page but correct orientation I hate looking at it sideways.

These look like just oil soaked felt wadded up inside very cool snap lids very cool old emerson moter.

Edit I am adding the picture from the vintage page but correct orientation I hate looking at it sideways.

Last edited: