I have the typical import tool post boring bar block. Its kind of heavy duty for my needs so mostly been a paperweight. It can hold a 1" OD shank boring bar or 3/4" OD using a split tube spacer. The block has 2 cap screws that squeeze down on the bar OD (or spacer). These boring bars are the typical offshore models with square broached holes to accommodate HSS blanks which you can grind to whatever profile. And that's exactly what I needed it for.

Anyway, I have smaller diameter bars in 1/2" and 5/8"diameter & wanted to marry them to the tool holder. Making the equivalent of the split tube for smaller bars is not a great plan because a) that's a long hole to drill out b) there is way too much meat left on the thicker wall thickness because of smaller ID, so it requires Hercules strength to clamp secure.

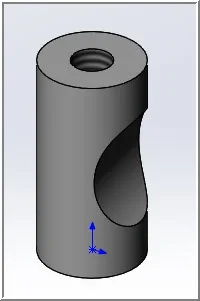

So I made 2 smaller inserts that basically plug into either end of the block. The bar is unsupported in the middle but inconsequential. My original plan was to slit saw cut through one side & then partially into the other wall as opposed to 2 separate halves. Well I think there is a magic formula about how much material to leave intact because mine were still very stiff. So I ended just halving them. Then I got an idea to bond soft durometer rubber sheet, 1/16" thick = slitting saw removal kerf. AliExpress to the rescue... maybe Jan-2017. I'm going to bond the rubber so the halves will stay intact, but rubber will easily squish when clamped (rubberized collet principle). It was one of those design-as-you-go type projects.

Yes, I could have milled flats on the bars for regular tool blocks or used the ones with V cut on bottom. This seemed easier (he says 4 hours later). An advantage of this tool block is it mostly stays on center +/- some minor adjustment.

Anyway, I have smaller diameter bars in 1/2" and 5/8"diameter & wanted to marry them to the tool holder. Making the equivalent of the split tube for smaller bars is not a great plan because a) that's a long hole to drill out b) there is way too much meat left on the thicker wall thickness because of smaller ID, so it requires Hercules strength to clamp secure.

So I made 2 smaller inserts that basically plug into either end of the block. The bar is unsupported in the middle but inconsequential. My original plan was to slit saw cut through one side & then partially into the other wall as opposed to 2 separate halves. Well I think there is a magic formula about how much material to leave intact because mine were still very stiff. So I ended just halving them. Then I got an idea to bond soft durometer rubber sheet, 1/16" thick = slitting saw removal kerf. AliExpress to the rescue... maybe Jan-2017. I'm going to bond the rubber so the halves will stay intact, but rubber will easily squish when clamped (rubberized collet principle). It was one of those design-as-you-go type projects.

Yes, I could have milled flats on the bars for regular tool blocks or used the ones with V cut on bottom. This seemed easier (he says 4 hours later). An advantage of this tool block is it mostly stays on center +/- some minor adjustment.