So my B&S Challenger surface grinder has a dust collector hiding in the base cabinet. I've had the machine now October 2018 and haven't had a good dust collection system. I usually just wedge the shop vac in the back dust catcher and carry on. I do notice the film of dust that accumulates everywhere and I really need to wear a dust mask when using it, but I'd like to also reduce the amount of dust that ends up everywhere in the shop. Now, I usually only grind small things so, and pretty infrequently so this hasn't been a priority, but for some reason this year I've decided to invest time in my shop. Could be because I spent the last 4 years rebuilding a cottage!

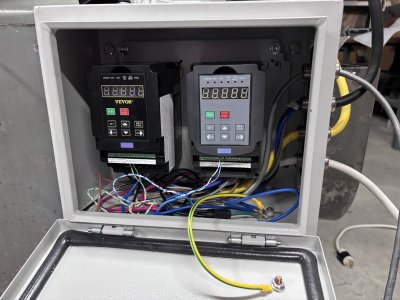

Anyways, the machine is 3 phase, so I added a VFD to it to make it run back in 2018. I just received my new to me (from Vevor) VFD to be able to run the dust extraction motor (1/2hp 3450rpm) and looking at it and the one from 2018 - no doubt in my mind the same factory made them. Some cosmetic differences in plastic but I'm pretty sure they are the same (both are 1hp rated).

Just waiting on a new box to house the pair of VFD's as the salvaged one I had previously is just too small. I also need to decide if I can live with basic light switches connected to the control terminals for on/off control or do I need more industrial looking switches, or go another way and use some sort of simple toggle switches. I have many momentary big push button switches, need to see if they can be used. Also have a few E-stop type. Momentary on, E-stop off? I need to read the manuals...

Anyways I thought I'd share some pics of the dust extractor as I haven't seem many of the originals on the web. I'm going to try it out with the original fabric filters, but I did see one guy modify it to use shop vac filters instead. If it does not suck in the dust then there is no point trying to filter it better.

If it works, the I can also look at using the dust collector for the bench grinder / belt sander and D bit grinder located in close proximity.

Anyways, the machine is 3 phase, so I added a VFD to it to make it run back in 2018. I just received my new to me (from Vevor) VFD to be able to run the dust extraction motor (1/2hp 3450rpm) and looking at it and the one from 2018 - no doubt in my mind the same factory made them. Some cosmetic differences in plastic but I'm pretty sure they are the same (both are 1hp rated).

Just waiting on a new box to house the pair of VFD's as the salvaged one I had previously is just too small. I also need to decide if I can live with basic light switches connected to the control terminals for on/off control or do I need more industrial looking switches, or go another way and use some sort of simple toggle switches. I have many momentary big push button switches, need to see if they can be used. Also have a few E-stop type. Momentary on, E-stop off? I need to read the manuals...

Anyways I thought I'd share some pics of the dust extractor as I haven't seem many of the originals on the web. I'm going to try it out with the original fabric filters, but I did see one guy modify it to use shop vac filters instead. If it does not suck in the dust then there is no point trying to filter it better.

If it works, the I can also look at using the dust collector for the bench grinder / belt sander and D bit grinder located in close proximity.