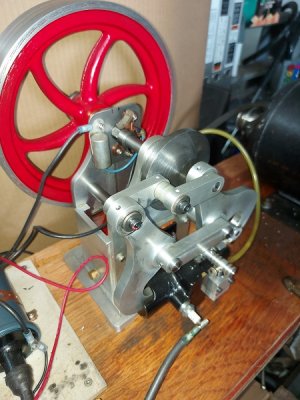

Has anybody here built the Atkinson Differential engine by Vincent R. Gingery and actually got it to run? I built one and it turned out very well. I went through the run in procedure by hooking it up to an electric motor and running it for hours. It seems like it is firing OK but not strong enough to actually run. Lots of talk about this online and the consensus of opinion is that there usually isn't enough compression to get it to fire strong enough to run. I went to a lot of trouble to be sure to get the ignition timing just right. Even hooked up an auto timing light to make sure. I got it out again yesterday to do some more investigating. Rolling it over by hand it seems to develop more compression if you roll it over in the opposite direction to the way it was designed. I have been thinking of trying it that way. All I would have to do is readjust the position of the ignition cam to change the firing position. Any thoughts on this ? I can't really think of why it would develop more compression turning that way.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Atkinson Differential Engine.

- Thread starter Larry_C9

- Start date

boilerhouse

Ultra Member

No help here but great job making that cool looking engine and I sure hope you can get it to run on its own. I was only vaguely aware of the type of design, so went onto YouTube to see one in action. Quite interesting, best of luck with yours.

Has anybody here built the Atkinson Differential engine by Vincent R. Gingery and actually got it to run?

No help here either Larry. I know absolutely squatt about engines like this.

But I do have some full size engine design experience. If you run dry of more knowledgeable more experienced input, I might be able to at least serve as a backstop to throw stuff at to see what bounces and what splatters.

The additional apparent compression might only be leverage differences and cam timing (assuming it has a cam).

This engine has poppet type inlet and exhaust valves. That is why I think it should be able to run in either direction with the timing readjusted for that rotation. There is a thread on the HMEM forum where a fellow was looking into this design and thought he might have some ideas on what to change to get better compression and thus a better running engine. I haven't read the whole thing yet but might look into it farther if I can't get this thing to try and run soon.No help here either Larry. I know absolutely squatt about engines like this.

But I do have some full size engine design experience. If you run dry of more knowledgeable more experienced input, I might be able to at least serve as a backstop to throw stuff at to see what bounces and what splatters.

The additional apparent compression might only be leverage differences and cam timing (assuming it has a cam).

historicalarms

Ultra Member

I've seen numerous diesel engines run backwards but have no experience with your engine . Usually a diesel will run backwards when it is sucked down to stalling and will for some reason fire backwards on its last dying stroke ....then be prepared for a $hit load of smoke & rattle noise ( the smoke exits the breather , not the exhaust, intake is through the exhaust pipe).

Pulling a diesel truck too low in rpms with the jake brake can do this. The other thing that will reverse is the oil pump....not good...I've seen numerous diesel engines run backwards but have no experience with your engine . Usually a diesel will run backwards when it is sucked down to stalling and will for some reason fire backwards on its last dying stroke ....then be prepared for a $hit load of smoke & rattle noise ( the smoke exits the breather , not the exhaust, intake is through the exhaust pipe).

Yes, I have first hand experience with what will happen when you let a diesel run backwards. I used to do a lot of repair work for a fellow that had a boat moving business. He had a 6 cylinder Cat engine in his truck and it was serving him very well. He was pulling the hill out of the boat ramp in Tofino one day and managed to stall the truck and bump it over back wards. When it started up backwards he didn't realize what was happening and let roll back down the hill before shutting it off because smoke was coming out of the air intake. He managed to start it up again and it seemed to run OK so he continued to use it. A while later ( weeks) the engine started to make a bit of a knocking noise so he brought it to me. I ended up pulling the pan off and found one rod bearing cap that looked like it had been too hot. To make a long story short it was just about to fly apart because the rod bearing was starting to pick up on the crankshaft. I ended up doing a total rebuild on the engine for him and the last I heard it was still going at well over a million miles. I must have done a pretty good job. I used to work for a Caterpillar dealer.

You might get some information from others who have built it or one like it on the model engineering forums

www.homemodelenginemachinist.com

www.homemodelenginemachinist.com

Home Model Engine Machinist Forum

Home model engine machinists & makers forum. Model engine making forums for engine plans, castings, CAD, CNC designs, lathe, Stirling, boilers & steam.

www.homemodelenginemachinist.com

www.homemodelenginemachinist.com

I did a bit of reading on the Ackinson model engines, some seem to suffer from low compression pressure. One person thought their's had only 2to1 compression. Some thought the port timing was out, I am a bit confused about that as they have poppet intake and a poppet exhaust. Opposed piston, ports and poppet valves?

I ran a Timber Jack loader for a while, with an 8v72 in it. Some days, it would not turn over due to low battery's, come up on compression on a cylinder and sit there. I go get a jumping truck, get back to find it merrily running and all was good. Thankfully running rite way.

I ran a Timber Jack loader for a while, with an 8v72 in it. Some days, it would not turn over due to low battery's, come up on compression on a cylinder and sit there. I go get a jumping truck, get back to find it merrily running and all was good. Thankfully running rite way.

I was told many years ago, that early Atlas? marine engines had big knobs on the heads, these were heated up with torches before starting engine. A hot head for starting! These also had air injection for turnning over the engine to start, didn't want air leaks, otherwise pumped up by hand.

Not all diesels use glow plugs, some used a prechamber system and other ways around the issue. Sometimes bit of rattling, banging, knocking noise until warmed up. A gas starting engine, or some were started on gas then switched to diesel when warmed up.

Any experience with some of these Larry_C9?

Not all diesels use glow plugs, some used a prechamber system and other ways around the issue. Sometimes bit of rattling, banging, knocking noise until warmed up. A gas starting engine, or some were started on gas then switched to diesel when warmed up.

Any experience with some of these Larry_C9?

Oh yes, Probably all of the above over a lot of years. If you want something really different, see if you can find anything on a Hesselman diesel. Not sure if I spelled it right. It was supposed to be the best features of a gasoline and diesel engine all rolled into one. It has had a magneto, spark plugs and a fuel injection system. There was one in an old shovel that was at the Vocational school where I took my initial training. They said it was the only one in captivity on the west coast at that time. In the early 1950s.I was told many years ago, that early Atlas? marine engines had big knobs on the heads, these were heated up with torches before starting engine. A hot head for starting! These also had air injection for turnning over the engine to start, didn't want air leaks, otherwise pumped up by hand.

Not all diesels use glow plugs, some used a prechamber system and other ways around the issue. Sometimes bit of rattling, banging, knocking noise until warmed up. A gas starting engine, or some were started on gas then switched to diesel when warmed up.

Any experience with some of these Larry_C9?

Sounds a bit like the propane diesels, had a propane mixer on intake, an ignition system, and then a small shot of diesel once burning. Have to see the Hesselman set up.

My bit of training was in the mid 70's, then back again in the mid 80's for a year. They were bringing in a electronic Detroit just before I left and wanted me to set it up, but money was real short in my pocket by then, so off to work, and slight change in work,life. No regrets.

My bit of training was in the mid 70's, then back again in the mid 80's for a year. They were bringing in a electronic Detroit just before I left and wanted me to set it up, but money was real short in my pocket by then, so off to work, and slight change in work,life. No regrets.

Update on the Atkinson compression problem. Yesterday I had some time so pulled the spark plug out and shone a light into the 3/16 hole into the cylinder barrel behind the spark plug cavity. Rotated the engine until the left piston came back on the intake stroke. At the end of it's stroke it just uncovered the 3/16 hole. Just where it is supposed to be. Rotating the engine farther to the compression stroke the right piston is supposed to come to 1/8 " of the left piston so it should be visible in the hole. It stopped moving somewhat short of the hole. So possibly if I can make a new link for the right side to bring that piston up closer to the left piston on the compression stroke it should possibly run. What I need to do now is turn the engine over until the right piston is all the way to the right and see if it goes far enough past the exhaust port, which is the farthest one to the right, to allow me to move that piston the required distance to the left. I know this is probably a bit confusing if you are not familiar with this engine. So if I get some time today I will remove the exhaust valve assembly and have a look in that port with the right piston all the way to the right. Stand by.

Update #2. Well I can't change the stroke position of the right piston because it just uncovers the exhaust port when it is all the way to the right. What I can probably do is add some aluminum to the top of the piston leaving a depression in the side that passes by the exhaust port. Looks like I can add at least 1/8" to the top. I think what I will do after taking some measurements is to make a plate to add to the top of the piston that I can retain with a couple of small flat head machine screws. I can leave a small opening in one side to allow it to still uncover the exhaust port. If that works I could make a new piston incorporating these changes or just leave it with the plate screwed to the top. After all this engine is never going to do any meaningful work.

The drawings are all in fractions, so not all that accurate. There was a fellow on the HMEM forum who was looking into why so many people had trouble getting these engines to run. He found that some of the dimensions were not good and was redrawing the plans and then was machining a new engine to try them out. I never got to the end of the thread yet because it was going on and on. That's what got me thinking I should have a closer look at mine.Following along.

So are the drawings not correct?

If your mod works will you make a new piston or just call it close enough?

If it works I will probably just leave the plate screwed to the top of the piston. It won't hurt anything and effectively will take up the space to increase the compression.

It has no cylinder head just 2 pistons in either end of the same cylinder. I did some somewhat rough calculations and if I put a .100 thick plate on top of one piston I should be able to decrease the volume of the combustion chamber when both pistons come together by about 45%. That should boost the compression somewhat.tak off the cyl head and use some plastercine to see how much you can add

It has no cylinder head just 2 pistons in either end of the same cylinder. I did some somewhat rough calculations and if I put a .100 thick plate on top of one piston I should be able to decrease the volume of the combustion chamber when both pistons come together by about 45%. That should boost the compression somewhat.

Hi Larry.

I'd recommend that you consider a few other things when increasing compression that much. I don't know what it is now, but a 45% increase could well cause the mixture to self ignite prematurely (diesel) with associated major engine damage.

Higher compression will also affect optimum ignition and valve timing.

A separate plate on top of the piston might cause the plate to run at a higher temperature too. Perhaps even hot enough to detonate the mixture.

Also, I'm not familiar with the design at all, but you might also consider the balancing effect of having one piston heavier than the other.