I intend to make some metric spur gears. Looks like lots of selection on cutter sets but for some reason, I don't see many matching arbors unless I'm looking in the wrong places. For the module series I'm interested in, nominal cutter hole ID is 16 & 22mm. Not sure about the key width yet but I'm sure the info is out there. I see plain arbors (no key) for slitting saws. I see shell end mill arbors with 2 key way tangs vs a single. Maybe the idea is you unscrew a tang to make it a single? Or what am I missing in the description? They don't look difficult to make but OTOH could be hardened & I wanted to see what commercial options are out there. I have R8 spindle but straight shank would be OK too.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

arbors for involute gear cutters

- Thread starter PeterT

- Start date

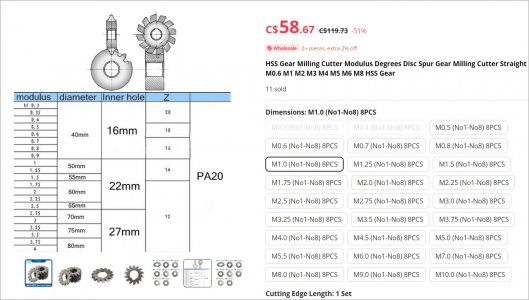

This is what I have coming.I intend to make some metric spur gears. Looks like lots of selection on cutter sets but for some reason, I don't see many matching arbors unless I'm looking in the wrong places. For the module series I'm interested in, nominal cutter hole ID is 16 & 22mm. Not sure about the key width yet but I'm sure the info is out there. I see plain arbors (no key) for slitting saws. I see shell end mill arbors with 2 key way tangs vs a single. Maybe the idea is you unscrew a tang to make it a single? Or what am I missing in the description? They don't look difficult to make but OTOH could be hardened & I wanted to see what commercial options are out there. I have R8 spindle but straight shank would be OK too.

ARMYJY 22mm R8 Shank Milling Arbor Gear Milling Cutter Holder Toolholding 7/16-20 for 22mm Gear Cutter or Other Milling Cutter https://a.co/d/f80b9G0

Matt-Aburg

Ultra Member

This week I have to do a simple slit cut on some custom marine bolt (sleeves). The cutter came in with a key, but the arbor is an R8, no key. I will take it easy on the cut, as it is stainless.I intend to make some metric spur gears. Looks like lots of selection on cutter sets but for some reason, I don't see many matching arbors unless I'm looking in the wrong places. For the module series I'm interested in, nominal cutter hole ID is 16 & 22mm. Not sure about the key width yet but I'm sure the info is out there. I see plain arbors (no key) for slitting saws. I see shell end mill arbors with 2 key way tangs vs a single. Maybe the idea is you unscrew a tang to make it a single? Or what am I missing in the description? They don't look difficult to make but OTOH could be hardened & I wanted to see what commercial options are out there. I have R8 spindle but straight shank would be OK too.

You would need the Key for your application I would think...

This week I have to do a simple slit cut on some custom marine bolt (sleeves). The cutter came in with a key, but the arbor is an R8, no key. I will take it easy on the cut, as it is stainless.

You would need the Key for your application I would think...

Yes, thats what I meant by looks like its integral to shank & spacers

Oddly I found no reference to key width so my fingers are crossed.@David_R8 when you were looking around, were you able to determine the corresponding key width? I assume it must be standardized to nominal arbor diameter, but who knows, maybe gear cutters are different?

Ya, I went through a similar thing with slitting saw arbors. There was a lot of badly made stuff out there, waste of money. The one that ran the best was the one I made myself. But cutting force & speed are quite low so straight shank & keyless was fine. But I suspect the gear cutter arbor should have a key. Not insurmountable to make, but one would think the arbor selection would be as plentiful as cutters but apparently not?

I see plain arbors (no key) for slitting saws. I see shell end mill arbors with 2 key way tangs vs a single. Maybe the idea is you unscrew a tang to make it a single? Or what am I missing in the description? They don't look difficult to make but OTOH could be hardened & I wanted to see what commercial options are out there.

All of my gear cutting arbours have a key.

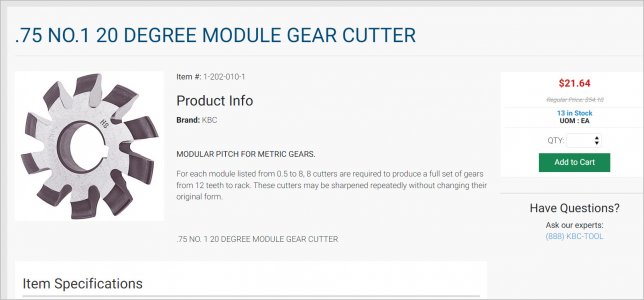

I got my gear cutters on Ali, but could not find arbours there either. I got my gear cutting arbours on Amazon. First I found the arbor I wanted and then found the cutters. The other way around didn't work for me. It was much easier to find cutters the right size for the arbour than it was to find an arbor the right size for the cutters.

https://a.co/d/gmgDM8c

You can also get arbours on Amazon that have machinable non-hardened ends.

https://a.co/d/9E2sX8I

As you note, the arbour you showed in your photo is a shell milling arbour. Some of the older face shells had different size dog slots. Easy to make dogs the size you need though.

https://a.co/d/eQRWzjE

Slitting saw arbors are different again. They typically have low clearance at the end so they can get in close to the work.

https://a.co/d/hlWmrdn

Ironman

Ultra Member

My Cat5 is a slitting saw arbor with one key out of it. I think I remember filing down the key to fit the gear hob as it was too proud of the slot. And then a hollow cap that the end screw clamped the hob with. Just drill the cap deep enough to clear the arbour sticking through the cutter.

I posted a parallel question on a model engineering forum & seems like many are dispensing with the key being unnecessary for smaller gear sizes, call it mod-1 or less just as example. So that would simplify things for a homebrew. Bigger gears likely require keys. A straight shank should be fine & gives more setup flexibility for work I anticipate.

Speaking of saw arbors, I'll have to check the ones I got off Ali. They are low profile & very well made. I have standardized on metric saws. But I suspect the engagement part for saws may not be quite enough for gear cutter thickness and/or mismatched body diameter.

Speaking of saw arbors, I'll have to check the ones I got off Ali. They are low profile & very well made. I have standardized on metric saws. But I suspect the engagement part for saws may not be quite enough for gear cutter thickness and/or mismatched body diameter.

Attachments

Those look very nice Peter.I posted a parallel question on a model engineering forum & seems like many are dispensing with the key being unnecessary for smaller gear sizes, call it mod-1 or less just as example. So that would simplify things for a homebrew. Bigger gears likely require keys. A straight shank should be fine & gives more setup flexibility for work I anticipate.

Speaking of saw arbors, I'll have to check the ones I got off Ali. They are low profile & very well made. I have standardized on metric saws. But I suspect the engagement part for saws may not be quite enough for gear cutter thickness and/or mismatched body diameter.

Two styles, one with a washer + screw bottom retainer, the other with a reverse thread top nut. Reasonably priced for quality. There are some nutso expensive USA & Euro ones out there. Maybe intended for industrial saws & applications, not sure.

I posted a parallel question on a model engineering forum & seems like many are dispensing with the key being unnecessary for smaller gear sizes, call it mod-1 or less just as example. So that would simplify things for a homebrew.

Despite the desirable simplification, I'd want the key anyway Peter. The gear cutter application is very much an interrupted cut which is like using an impact driver. I wouldn't want the cutter spinning or the nut tightening up excessively. Certainly rpm and feed rate would affect the risk of that. The key addresses that risk. I don't have any empiracle numbers to support that view though. It's just me preferring the safer path.

Brent H

Ultra Member

I suggest having the keyway, especially for gear cutting. The more solid the set up, the better. Some of the slitting saws I have are over 1/4” wide, the key is necessary, tool slippage can gaul up the arbour faces, the cutter or create heat that warps or takes out the hardness. You can always take out the key from the arbour and run round hole cutters but if they have a keyway, best to use it.

Here is one I made years ago. Advantage of a shop-made one is you can do the final pass(es) while the arbour is in the mill with either a lathe tool in the vice or a TPG. You’ll end up with near zero runout. In case of the R-8 system, it will always run true afterwards, even after re-installing, since you have the little locating pin, assuring identical clocked position in the spindle.

I drilled a hole (bigger than the largest key on my cutters) and lightly pressed in a piece of brass. Squaring off the round sides with a file makes it easy to tailor the keys to the different size key ways my cutters have.

The brass will also shear long before any damage is done to either cutter or the arbour in case of a mishap.

I drilled a hole (bigger than the largest key on my cutters) and lightly pressed in a piece of brass. Squaring off the round sides with a file makes it easy to tailor the keys to the different size key ways my cutters have.

The brass will also shear long before any damage is done to either cutter or the arbour in case of a mishap.