-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone using natural gas for their forge

- Thread starter djberta

- Start date

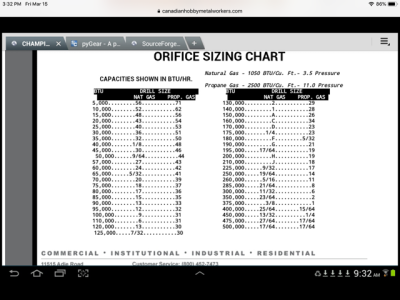

I'm using nat gas now. And @David is correct. You have to change the jet size. I can't find the files or information on what I did.

One thing to keep in mind, in the old days the gas pressure after the house meter/regulator was pretty low. Now it's around 2 or 3 PSI and BBQs use about 0.7 PSI. The propane foundries tend to run at least 10-15 PSI IIRC. BBQs drop the pressure down to 0.7 PSI again IIRC.

One thing to keep in mind, in the old days the gas pressure after the house meter/regulator was pretty low. Now it's around 2 or 3 PSI and BBQs use about 0.7 PSI. The propane foundries tend to run at least 10-15 PSI IIRC. BBQs drop the pressure down to 0.7 PSI again IIRC.

The burn temperature of natural gas and propane is very close, like withen 100f, i think the low pressure is why you would need that larger jet

edit ; found it, the btu content is considerably lower in natural gas that's the reason it seems "colder", 2500btu per cu/ft of propane, 1050btu per cu/ft of natural gas, so you are going to burn 2.5x the natural gas to get the same energy output as propane, probably still considerably cheaper though

edit ; found it, the btu content is considerably lower in natural gas that's the reason it seems "colder", 2500btu per cu/ft of propane, 1050btu per cu/ft of natural gas, so you are going to burn 2.5x the natural gas to get the same energy output as propane, probably still considerably cheaper though

Yes. Back when I was using Propane each melt into my #6 crucible used about 1.5 lbs of propane and once the 20# bottle was more than half empty the pressure dropped enough that a refill was needed. I think each melt was costing me about $2.The burn temperature of natural gas and propane is very close, like withen 100f, i think the low pressure is why you would need that larger jet

edit ; found it, the btu content is considerably lower in natural gas that's the reason it seems "colder", 2500btu per cu/ft of propane, 1050btu per cu/ft of natural gas, so you are going to burn 2.5x the natural gas to get the same energy output as propane, probably still considerably cheaper though

With the Nat Gas I barely notice it on my bill because of all the extraneous costs like transportation etc.

I have, as expected since I'm rather anal, a computer module running my furnace. Spark Plug Ignition and project 42 was to install the flame detector which is still sitting in the box.Im sure its worth it to not have to fill a bottle all the time either, just dont forget to turn it off!

To light the furnace the lid is opened. Master ball valve on wall turned on. Valve on furnace turned to on. Then Start button pressed. Fan starts up at slow speed. Spark starts. Solenoid clicks open and furnace goes woosh as the gas lights. Orange/Yellow flames billowing out the top. Fan then ramps up to full speed, flame withdraws and becomes nice blue aimed at the bottom side of the crucible. Spark has stopped after flame started.

Switching off cuts gas, flame goes out, fan cycles down to low speed for a few seconds and then off. There is a switch setting for low speed continuous to slowly cool the furnace and heat the shop.

There is no gas regulator so pressure is about 2 or 3 PSI. Hence a fan is mandatory to get decent flame and heat.

Mark Presling built a diesel fired forge.

youtube.com

youtube.com

Diesel Furnace Burner For Your Foundry

A DIY diesel fuelled furnace burner and service cart that doesn't require any compressed air. The design was based on a version I saw on SWDWEEB's channel. T...

The biggest reason to go nat gas for me is to not have to keep getting propane. I don't think I would be building an automatic system any time soon. Although I do have an ignitor here for another project. Could a water tank or heater gas valve be used? I have seen the waste oil ones and talked to one of the ytubers back several years ago and he said it can be a mess. But it smells like you cooking fries all the time.

The biggest reason to go nat gas for me is to not have to keep getting propane. I don't think I would be building an automatic system any time soon. Although I do have an ignitor here for another project. Could a water tank or heater gas valve be used? I have seen the waste oil ones and talked to one of the ytubers back several years ago and he said it can be a mess. But it smells like you cooking fries all the time.

I dont know if either of those valves would flow enough, but they are reliable, assuming you didn't melt the thermocouple, you could potentially mount it in the burner tube off to the side so that it didnt get overly hot

I was thinking more waste engine oil, but the smell and smoke had concerned me, the neighbors may not take kindly to it if it smokes out the whole backlane, i might have to experiment, see how cleanly it burns

Dan Dubeau

Ultra Member

Just start it on waste veggie oil so they get a whiff of french fries, get the munchies, then run out for McD's. When they're gone, switch over to the used motor oil. 😀

Proxule

Ultra Member

Can you show us your setup, details, etc etc?I’m running natural gas, naturally aspirated, melting bronze.

Thanks!

The more important reason is to not worry about bottle freeze.The biggest reason to go nat gas for me is to not have to keep getting propane

20lbs bottles freeze up too fast when forge welding. The 100lbs ones are better, but the last 20-30lbs freeze up the same way. You won't have that problem with municipal gas service.

Though these days I'm using my induction forge much more often than the gas.

Technically, yes put together a siphon nozzle setup. Run it on kero or diesel for the most part. Total overkill for aluminum. Also have a Moya style drip burner which has a propane inlet for preheat...usually just use it as forced air/propane for aluminum.sounds high tech

have you or anyone else here built a waste oil burner ? a foundry furnace has been a back burner idea for a long while, and i always have a pile of used motor oil....

Attachments

Tobho Mott

Well-Known Member

I haven't tried natural gas for foundry. Only know of a couple people who have...

But did someone say waste oil burner???

I do use gravity fed drip injection type waste oil burners in my furnaces. Mine are loosely based on Lionel Oliver's Brute and Hot Shot burner designs (https://backyardmetalcasting.com/oilburners10.html)

Lionel was the man behind the old alloyavenue forums which are no more, but his personal website is still up... For the time being.

These burners require forced air and a preheated furnace to vaporize oil drips that get blown into the furnace. For this reason they also work as forced air propane burners.

My small low mass furnace heats up so fast it almost seems silly to drag out the bigger blower and set up the oil tank and line etc., so usually I just run it as a propane furnace using about 5psi of propane with a hair dryer for the forced air. Ideal for one and done melts starting from cold.

But for bigger melts or when I have to do back to back melts, I use a heavier duty furnace with a 5 gallon bucket shop vac power head blower and switch over to a waste oil drip controlled by a needle valve once the propane gets the furnace glowing hot inside. This preheat takes about 2/3 as long as a full melt from cold in the small furnace, then I can start the oil drip and really get going. So with the additional thermal mass of it plus it's larger size it's a lot slower to get the first melt done, but after that it really rips. That is also the setup I'll be using for my upcoming first cast iron attempt, since an oil burner can get you there easier than propane. Although I'll probably use diesel and not waste oil. It'll burn waste motor oil or waste cooking oil (or jet-A, kerosene, whatever) just fine once the furnace is hot, but diesel is pretty darn convenient.

Ignore the incomplete one on the bottom of the pic for now. The smaller one above it has served me well since 2015. The oil line quick connects into the very back end of the burner and runs through a thin central tube (seen in the one you're ignoring, but hidden inside the 1" burner tube of the one you're looking at) to the very end of the burner tube. Air (and propane, during preheat) get sent through the 1" tube through a line that is hidden on the underside of the tee in this pic. There is no jet, just a 1/4" npt fitting that dumps gas into the tube (there's a 0-10 psi adjustable regulator on the gas line, more than enough gas to preheat the big furnace for waste oil or take 30# of bronze to pouring temp in 25 minutes in the little one. And there's a ball valve to.quickly cut off the gas if needed. The largest tube on the outside is just a sleeve to hold it centered at the correct depth in my furnace tuyere. The gap between it and the 1" tube is stuffed with kaowool to keep flames from blowing back out toward the fuel lines and valves between the 2 tubes.

Simple as can be. No need to run compressed air to run a siphon nozzle, no complicated nozzles to clog up on you if your oil isn't so well filtered. I do have to blow a few french fry crumbs out of the needle valve every so often.

The siphon nozzle option has its advantages too like not needing any preheat to light and needing less adjusting mid-melt to maintain tune. Delevan is the name of the company that makes the nozzles. You also need an adaptor that goes with it. Similar to nozzles used in home heating oil burners, but those use a fuel pump not a siphon and they won't like waste oil. You could build a pumped diesel-only burner with one of those though.

The Kwiky All Fuel Burner is a popular homemade oil burner that uses a diy.siphon nozzle. Many backyard metal casters have vouched for it, so that might be another option:

Dave was a regular on the old AlloyAvenue forums

If interested, I have an oil burner playlist on my YouTube showing my oil burners being built, used, taken apart and cleaned, etc.

Good luck!

Jeff

But did someone say waste oil burner???

I do use gravity fed drip injection type waste oil burners in my furnaces. Mine are loosely based on Lionel Oliver's Brute and Hot Shot burner designs (https://backyardmetalcasting.com/oilburners10.html)

Lionel was the man behind the old alloyavenue forums which are no more, but his personal website is still up... For the time being.

These burners require forced air and a preheated furnace to vaporize oil drips that get blown into the furnace. For this reason they also work as forced air propane burners.

My small low mass furnace heats up so fast it almost seems silly to drag out the bigger blower and set up the oil tank and line etc., so usually I just run it as a propane furnace using about 5psi of propane with a hair dryer for the forced air. Ideal for one and done melts starting from cold.

But for bigger melts or when I have to do back to back melts, I use a heavier duty furnace with a 5 gallon bucket shop vac power head blower and switch over to a waste oil drip controlled by a needle valve once the propane gets the furnace glowing hot inside. This preheat takes about 2/3 as long as a full melt from cold in the small furnace, then I can start the oil drip and really get going. So with the additional thermal mass of it plus it's larger size it's a lot slower to get the first melt done, but after that it really rips. That is also the setup I'll be using for my upcoming first cast iron attempt, since an oil burner can get you there easier than propane. Although I'll probably use diesel and not waste oil. It'll burn waste motor oil or waste cooking oil (or jet-A, kerosene, whatever) just fine once the furnace is hot, but diesel is pretty darn convenient.

Ignore the incomplete one on the bottom of the pic for now. The smaller one above it has served me well since 2015. The oil line quick connects into the very back end of the burner and runs through a thin central tube (seen in the one you're ignoring, but hidden inside the 1" burner tube of the one you're looking at) to the very end of the burner tube. Air (and propane, during preheat) get sent through the 1" tube through a line that is hidden on the underside of the tee in this pic. There is no jet, just a 1/4" npt fitting that dumps gas into the tube (there's a 0-10 psi adjustable regulator on the gas line, more than enough gas to preheat the big furnace for waste oil or take 30# of bronze to pouring temp in 25 minutes in the little one. And there's a ball valve to.quickly cut off the gas if needed. The largest tube on the outside is just a sleeve to hold it centered at the correct depth in my furnace tuyere. The gap between it and the 1" tube is stuffed with kaowool to keep flames from blowing back out toward the fuel lines and valves between the 2 tubes.

Simple as can be. No need to run compressed air to run a siphon nozzle, no complicated nozzles to clog up on you if your oil isn't so well filtered. I do have to blow a few french fry crumbs out of the needle valve every so often.

The siphon nozzle option has its advantages too like not needing any preheat to light and needing less adjusting mid-melt to maintain tune. Delevan is the name of the company that makes the nozzles. You also need an adaptor that goes with it. Similar to nozzles used in home heating oil burners, but those use a fuel pump not a siphon and they won't like waste oil. You could build a pumped diesel-only burner with one of those though.

The Kwiky All Fuel Burner is a popular homemade oil burner that uses a diy.siphon nozzle. Many backyard metal casters have vouched for it, so that might be another option:

If interested, I have an oil burner playlist on my YouTube showing my oil burners being built, used, taken apart and cleaned, etc.

Good luck!

Jeff