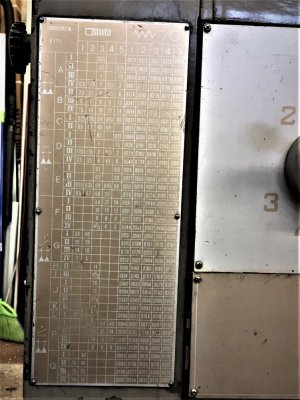

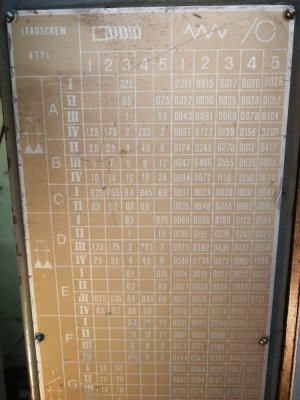

Attached pic of my gear train, I can only cut threads section F 36 thru 3,

i have zero info for this lathe, my quest is to cut proper change gears for threads and feed listed, doesn't seem to have a lot of options.

it appears as there are 2 spots for extra gears

"oops all the pic are rotatedView attachment 13206

i have zero info for this lathe, my quest is to cut proper change gears for threads and feed listed, doesn't seem to have a lot of options.

it appears as there are 2 spots for extra gears

"oops all the pic are rotatedView attachment 13206

Attachments

Last edited: