Do any of you CNC folks have experience or maybe other forum links / user experience to these Chinese motor packages? They seem like a good value but who knows. I really like the rectangular form factor + air vs water cooled + potential for 110V input vs 220V. But voltage is where things get fuzzy - is that a VFD programming thing or very specific VFD/motor package or...? I know CNC milling (routing) is probably where these are used 95% of the time bit I have o other, somewhat similar, projects in mind.

-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

-

Several Regions have held meetups already, but others are being planned or are evaluating the interest. The Calgary Area Meetup is set for Saturday July 12th at 10am. The signup thread is here! Arbutus has also explored interest in a Fraser Valley meetup but it seems members either missed his thread or had other plans. Let him know if you are interested in a meetup later in the year by posting here! Slowpoke is trying to pull together an Ottawa area meetup later this summer. No date has been selected yet, so let him know if you are interested here! We are not aware of any other meetups being planned this year. If you are interested in doing something in your area, let everyone know and make it happen! Meetups are a great way to make new machining friends and get hands on help in your area. Don’t be shy, sign up and come, or plan your own meetup!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Air cooled VFD spindle motor packages

- Thread starter PeterT

- Start date

Sure do.

I have a round water-cooled 2.2Kw spindle with a 120v VFD on my PrintNC CNC router.

The thing about the round sindles is that they can be slid up and down in the motor mount.

When I bought it I didn't want to run another 240v circuit for the VFD so I went the 120v route.

I expected the VFD to take 120v isingle phase in and output 240 3-phase as that's what I had from my 120v Teco VFD that I used on my surface grinder.

What I subsequently learned is that the Chinese 120v input VFDs produce 120v 3-phase power and the spindle is built for that.

I called pretty much every VFD supplier in North America to find a brand name 120v in, 120v out VFD and no such device exists.

So if my VFD blows up (they are not terribly reliable) I have to either buy another of the same and hope for the best or buy a 240v spindle and a name brand VFD.

Were I to do it over again I'd buy the 240v version so that I had brand name VFD options in the future.

The VFD programming has no effect on voltage. Only start up parameters, remote control options etc.

I have a round water-cooled 2.2Kw spindle with a 120v VFD on my PrintNC CNC router.

The thing about the round sindles is that they can be slid up and down in the motor mount.

When I bought it I didn't want to run another 240v circuit for the VFD so I went the 120v route.

I expected the VFD to take 120v isingle phase in and output 240 3-phase as that's what I had from my 120v Teco VFD that I used on my surface grinder.

What I subsequently learned is that the Chinese 120v input VFDs produce 120v 3-phase power and the spindle is built for that.

I called pretty much every VFD supplier in North America to find a brand name 120v in, 120v out VFD and no such device exists.

So if my VFD blows up (they are not terribly reliable) I have to either buy another of the same and hope for the best or buy a 240v spindle and a name brand VFD.

Were I to do it over again I'd buy the 240v version so that I had brand name VFD options in the future.

The VFD programming has no effect on voltage. Only start up parameters, remote control options etc.

Mine is some weird device.

I had thought it was just a DC motor with variable voltage speed control. It isn't.

I believe it was @whydontu who told me it might be a duty cycle speed control. This turns out to be partly true. I put a scope on it and it is definitely variable duty cycle variable voltage. Really different. The power unit came with it but seems under powered. I'd like to try increasing its power delivery cuz I think the motor is dragging it down.

I've been trying to get info on how it is supposed to work as well as its limits. Hence my interest in your thread.

I had thought it was just a DC motor with variable voltage speed control. It isn't.

I believe it was @whydontu who told me it might be a duty cycle speed control. This turns out to be partly true. I put a scope on it and it is definitely variable duty cycle variable voltage. Really different. The power unit came with it but seems under powered. I'd like to try increasing its power delivery cuz I think the motor is dragging it down.

I've been trying to get info on how it is supposed to work as well as its limits. Hence my interest in your thread.

Thanks David. 220V motor + 220V VFD package seems to be the predominant combination. 110V would allow me to be on a separate circuit while running a 220V machine but hopefully the amp draw on 220V spindle would not be problematic given the spindle watt rating. Do you happen to know what kind of amp draw your 2.2KW is pulling now? Is yours a water or air cooled? Any comments on the plug type 1 vs 2, aviation vs 'regular? How was the VFD programming instructions, is some prior or outside familiarity required? Are you saying if you had a TECO you could just as easily hook it up to the 220V motor?

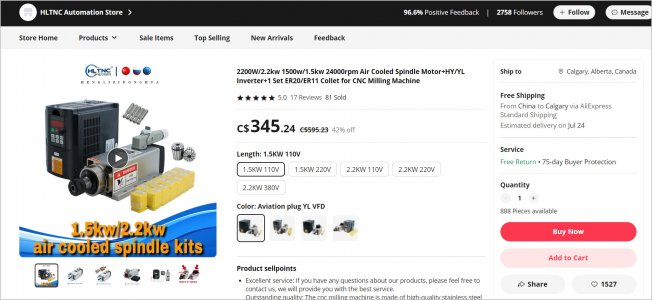

www.aliexpress.com

www.aliexpress.com

CNC Spindle 2.2kw 1.5kw 24000rpm Air Cooled Spindle Motor YL HS VFD Inverter +1 Set ER20 or ER11 Collet for CNC Milling Machine - AliExpress 202216001

Smarter Shopping, Better Living! Aliexpress.com

Thanks David. 220V motor + 220V VFD package seems to be the predominant combination.

Hey Peter, your last two photos appear to be the same. Was that intentional?

Mine is water cooled.Thanks David. 220V motor + 220V VFD package seems to be the predominant combination. 110V would allow me to be on a separate circuit while running a 220V machine but hopefully the amp draw on 220V spindle would not be problematic given the spindle watt rating. Do you happen to know what kind of amp draw your 2.2KW is pulling now? Is yours a water or air cooled? Any comments on the plug type 1 vs 2, aviation vs 'regular? How was the VFD programming instructions, is some prior or outside familiarity required? Are you saying if you had a TECO you could just as easily hook it up to the 220V motor?

CNC Spindle 2.2kw 1.5kw 24000rpm Air Cooled Spindle Motor YL HS VFD Inverter +1 Set ER20 or ER11 Collet for CNC Milling Machine - AliExpress 202216001

Smarter Shopping, Better Living! Aliexpress.comwww.aliexpress.com

View attachment 36125

No idea of the amp draw but I run all of the electronics off a 15A breaker so the draw is less than 15A even on start up.

I went with the aviation style plug but mainly because that’s what it came with.

Yes if I had the 240v spindle I could get a 120V or 240V vfd.

Weird, when I went to edit it showed triplets. The single pic showing both styles will sufficeHey Peter, your last two photos appear to be the same. Was that intentional?

Just so I'm clear, if you buy 120V motor, can the same VFD model deliver 120V or 240V by programming or switch? Or you need to make ensure its a matching voltage 240/240 or 120/120 etcYes if I had the 240v spindle I could get a 120V or 240V vfd.

No if you buy a 120v spindle you get a 120v output vfd.Just so I'm clear, if you buy 120V motor, can the same VFD model deliver 120V or 240V by programming or switch? Or you need to make ensure its a matching voltage 240/240 or 120/120 etc

VFDs do not have programmable input/output voltages.

Just so I'm clear, if you buy 120V motor, can the same VFD model deliver 120V or 240V by programming or switch? Or you need to make ensure its a matching voltage 240/240 or 120/120 etc

What David said. At least so far as I know.

But never say never. Having said it, someone will introduce one tomorrow or find something I didn't know existed.

No if you buy a 120v spindle you get a 120v output vfd.

VFDs do not have programmable input/output voltages.

So, I'm struggling too David. Just not the same way as @PeterT.

VFD means Variable Frequency Drive. So strictly speaking, I assume your spindle motor changes speed by changing frequency. No?

So why do some (for example mine) change speed by changing duty cycle and voltage?

Also, mine will change speed from virtually zero through to 16,000 rpm. That's way beyond what a regular motor does with variable frequency.

That said, nothing on my motor speed control says that it's a VFD.

So what's the story with that? Is there more than one kind of spindle motor?

I have the 2.2kw water cooled vfd spindle in my print nc as well, the 240v version

Draws around 9a on the 240v circuit, excessive start current isn't really a thing with the vfd, a slow ramp up speed takes care of that, 2.2kw on 120v would max out a 20a circuit (would be around 18a+19a draw)

I would not go with an air cooled spindle, they are apparently considerably louder, like palm router loud, the water cooled spindle on the other hand is very quiet (on it's own not cutting)

They do sell the 1.5kw water cooled spindle for 110v, it would need a it's own circuit as well, but comes with a much smaller collet than the 2.2kw version (2.2kw comes with er20)

It seems overall the 2.2kw spindle is the best money spent, assuming you have the extra bucks to spend, and it's not to physically large and heavy (the 2.2kw is much larger and the pictures make it seem...and quite heavy)

Draws around 9a on the 240v circuit, excessive start current isn't really a thing with the vfd, a slow ramp up speed takes care of that, 2.2kw on 120v would max out a 20a circuit (would be around 18a+19a draw)

I would not go with an air cooled spindle, they are apparently considerably louder, like palm router loud, the water cooled spindle on the other hand is very quiet (on it's own not cutting)

They do sell the 1.5kw water cooled spindle for 110v, it would need a it's own circuit as well, but comes with a much smaller collet than the 2.2kw version (2.2kw comes with er20)

It seems overall the 2.2kw spindle is the best money spent, assuming you have the extra bucks to spend, and it's not to physically large and heavy (the 2.2kw is much larger and the pictures make it seem...and quite heavy)

So what's the story with that? Is there more than one kind of spindle motor?

Did a bit of my own research last night. Seems that there are indeed many varients. Brushed & brushless, DC & AC, 1ph & 3ph, 100W to 2.2KW, air cooled and water cooled.

Mine appears to be Brushed, DC, Air Cooled, 500Watts. That explains the weird controller. It is probably designed to do exactly what I measured which was to control voltage, duty cycle, and frequency in order to reliably fine tune speed across a very wide range. I don't know what happens under load, but I would guess that the voltage deteriorates as the current at a given speed setting increases.

I might try to find a better controller that can supply the rated power. I don't have the patience to make something especially given the number of projects on my plate.

Yes a VFD controls motor speed by varying the frequency. 60hz is full rated speed. 30hz would be roughly half rated speed.So, I'm struggling too David. Just not the same way as @PeterT.

VFD means Variable Frequency Drive. So strictly speaking, I assume your spindle motor changes speed by changing frequency. No?

So why do some (for example mine) change speed by changing duty cycle and voltage?

Also, mine will change speed from virtually zero through to 16,000 rpm. That's way beyond what a regular motor does with variable frequency.

That said, nothing on my motor speed control says that it's a VFD.

So what's the story with that? Is there more than one kind of spindle motor?

I can’t comment on other motor drives as I have zero experience with them.

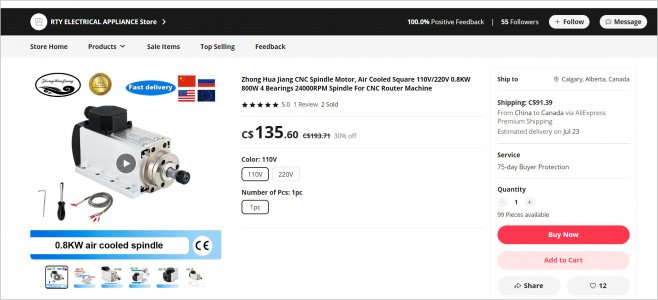

I messaged an Ali seller about the 110V 800 watt version. It kind of appears they could match the appropriate VFD? Actually 800w would be plenty of power & 110V would offer me some advantages.

Just wish I could see more details, download some specs or a manual. Maybe this is kind of like the oddity VFD @David88 was referring to? Well, at least they replied.

Just wish I could see more details, download some specs or a manual. Maybe this is kind of like the oddity VFD @David88 was referring to? Well, at least they replied.

Thanks.I have the 2.2kw water cooled vfd spindle in my print nc as well, the 240v version

Draws around 9a on the 240v circuit, excessive start current isn't really a thing with the vfd, a slow ramp up speed takes care of that, 2.2kw on 120v would max out a 20a circuit (would be around 18a+19a draw)

I would not go with an air cooled spindle, they are apparently considerably louder, like palm router loud, the water cooled spindle on the other hand is very quiet (on it's own not cutting)

- so do you run the water circulation system I often see packaged with these spindles or something you created yourself? The packaged one looks plug & play, nut yet another hookup. However like you say quieter & heat no longer issue. Internally the bearings look quite similar between the 2 styles.

- my issue is I would see sporadic use maybe 15 minutes, then a rest. Not routing big projects over extended time. It must be the air/fan noise that makes them worse I imagine. I wonder what the dB difference is

i have seen kits that come with the appropriate vfd for all of the common sizes of spindle, air cooled and water cooled versions

check amazon, i found the prices on amazon and ali to be the same, sometimes less on amazon, at least with amazon you have more options if there is a problem

i run the pump that it came with, just in a bucket of distilled water, i did order/use nicer silicon hose for it however

i wouldn't chance running it for 15 minutes without any cooling, it might be ok, it might burn up in the first minute, it really has no way of dissipating heat without the water jacket

you can run an ssr from the vfd to turn the pump on when the vfd turns the spindle on (the vfd has outputs for this)

there are some youtube videos comparing the noise, i dont have an air-cooled spindle to directly compare it to, but i can tell you the water cooled one may be 80db-85db at most? it is honestly very quite on its own, not much louder than the fan in the vfd

check amazon, i found the prices on amazon and ali to be the same, sometimes less on amazon, at least with amazon you have more options if there is a problem

Thanks.

- so do you run the water circulation system I often see packaged with these spindles or something you created yourself? The packaged one looks plug & play, nut yet another hookup. However like you say quieter & heat no longer issue. Internally the bearings look quite similar between the 2 styles.

- my issue is I would see sporadic use maybe 15 minutes, then a rest. Not routing big projects over extended time. It must be the air/fan noise that makes them worse I imagine. I wonder what the dB difference is

View attachment 36153View attachment 36154

i run the pump that it came with, just in a bucket of distilled water, i did order/use nicer silicon hose for it however

i wouldn't chance running it for 15 minutes without any cooling, it might be ok, it might burn up in the first minute, it really has no way of dissipating heat without the water jacket

you can run an ssr from the vfd to turn the pump on when the vfd turns the spindle on (the vfd has outputs for this)

there are some youtube videos comparing the noise, i dont have an air-cooled spindle to directly compare it to, but i can tell you the water cooled one may be 80db-85db at most? it is honestly very quite on its own, not much louder than the fan in the vfd