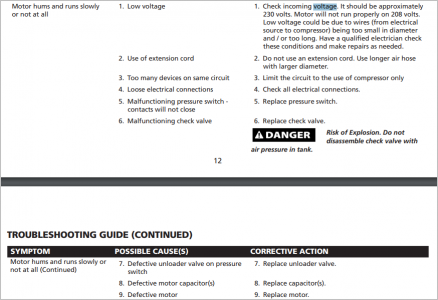

My Air compressor keeps tripping the breaker when ever it tries to start pumping more air into the tank with any pressure above 10 psi. When I use my plasma cutter and the compressor looses too much pressure, I need to empty the remaining air pressure for it to start and keep running without tripping the breaker. It can keep running all the way to 120 psi from 0, most likely by the strength/energy of the momentum from the higher speed of the motor at a lower level of resistance.

I already tried replacing the oil, and emptying the water, now I'm wondering if it would work if I purchased a new and maybe higher powered motor for replacement.

I already tried replacing the oil, and emptying the water, now I'm wondering if it would work if I purchased a new and maybe higher powered motor for replacement.