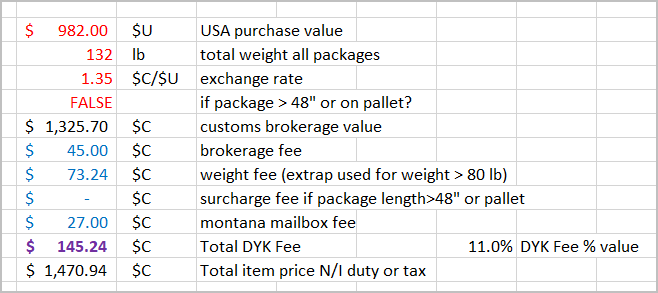

I haven't really followed when the switch occurred but now they sell the 5C collet version like Shars & other sellers have offered for quite some time. It used to be R8 only. I ran into a dead end trying to buy the 5C work head separately only because I have a full set of 5C collets. Oh well, I can use R8's in my mill too. Unfortunately the price on these machines has increased dramatically.

accusizetools.com

accusizetools.com

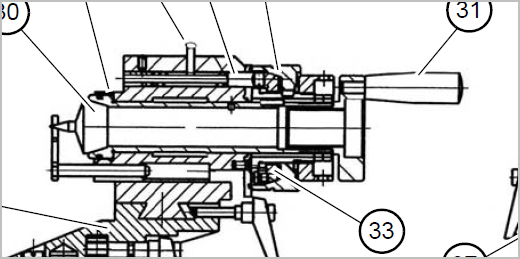

5C SINGLE LIP CUTTER GRINDER DECKEL STYLE PERFECTLY BUILT

Best Single Lip Grinder Finally, we thought we had better offer a small universal and single lip cutter grinder. Our research found that the CM-U35C Single Lip Grinder is the best machine of its class out there, and is good for almost anything in the right hands. Made famous by our friends at...