guitarchitect

Member

Hi Everyone,

I haven't even gotten my lathe yet but I wanted to put this question out there as it's hard to "find" this information on the web. I nearly bought a Taig CNC lathe but it just didn't have the flexibility that i needed - i need tailstock support for what i do, and generally needed more space than the taig would provide.

Primarily my question is this - once you've done a conversion, how easy/hard is it to do manual operations? Is it as simple as getting a pendant and just getting used to using it, or do you find that you will just write quick programs in conversational g-code?

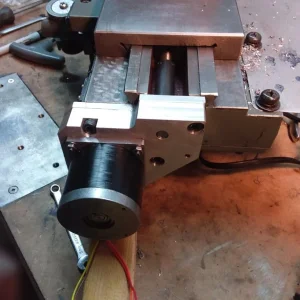

I've seen Wade'O Designs' incredibly CNC conversion where he retained manual control with his handwheels, but for me the lathe is a means to an end (I make pens), not the project/hobby in itself. I do small production runs and need to be operational most days of the week. He's also done a substantial amount of mill work and that's not something I'm capable of - i'm strictly looking at a conversion kit from BD tools or the like.

Generally speaking I would use the CNC for tenons and threading triple-start threads at various sizes, in addition to shaping pen bodies and caps. But i'd also be using the lathe in manual mode for some of the stranger materials that i use, putting a dremel on the tool post, making inlay rings, accent rings, the odd bit of hardware for cabinets i make around the house, etc. I'm just hoping to understand what post-conversion use of the lathe looks like, so any insight you can provide would be much appreciated!

I haven't even gotten my lathe yet but I wanted to put this question out there as it's hard to "find" this information on the web. I nearly bought a Taig CNC lathe but it just didn't have the flexibility that i needed - i need tailstock support for what i do, and generally needed more space than the taig would provide.

Primarily my question is this - once you've done a conversion, how easy/hard is it to do manual operations? Is it as simple as getting a pendant and just getting used to using it, or do you find that you will just write quick programs in conversational g-code?

I've seen Wade'O Designs' incredibly CNC conversion where he retained manual control with his handwheels, but for me the lathe is a means to an end (I make pens), not the project/hobby in itself. I do small production runs and need to be operational most days of the week. He's also done a substantial amount of mill work and that's not something I'm capable of - i'm strictly looking at a conversion kit from BD tools or the like.

Generally speaking I would use the CNC for tenons and threading triple-start threads at various sizes, in addition to shaping pen bodies and caps. But i'd also be using the lathe in manual mode for some of the stranger materials that i use, putting a dremel on the tool post, making inlay rings, accent rings, the odd bit of hardware for cabinets i make around the house, etc. I'm just hoping to understand what post-conversion use of the lathe looks like, so any insight you can provide would be much appreciated!