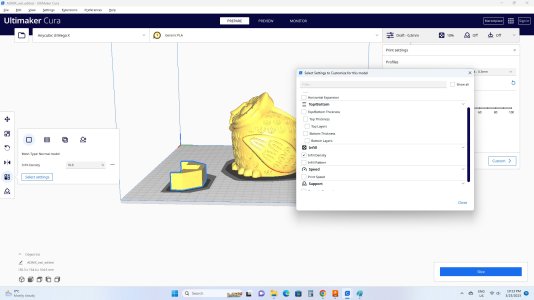

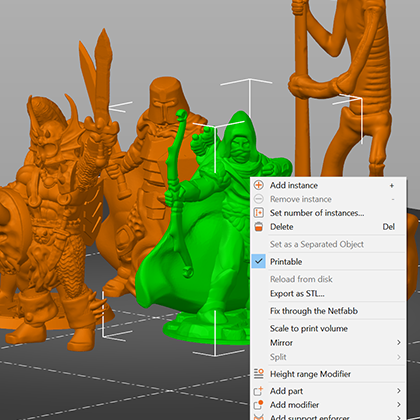

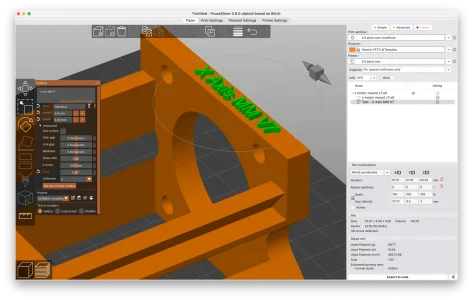

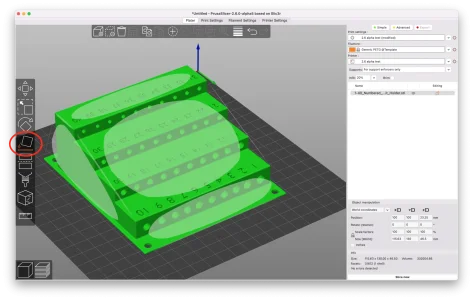

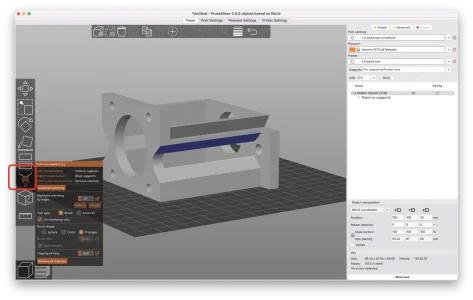

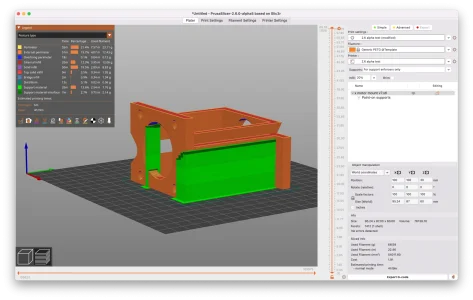

I've only used the one slicer Prusa Slicer other than looking at the bambu slicer a few times. I'm wondering if there are other slicers with better control over print parameters when you are printing multiple objects simultaneously. For example I want to print a drive coupler with 100% perimeters and full infill and at the same time print a motor mount which only needs 4 perimeters and maybe a 20% infill. To do that I have to print the first part in one session and the second part in another. Is there another slicer which provides this level of control?

Last edited: