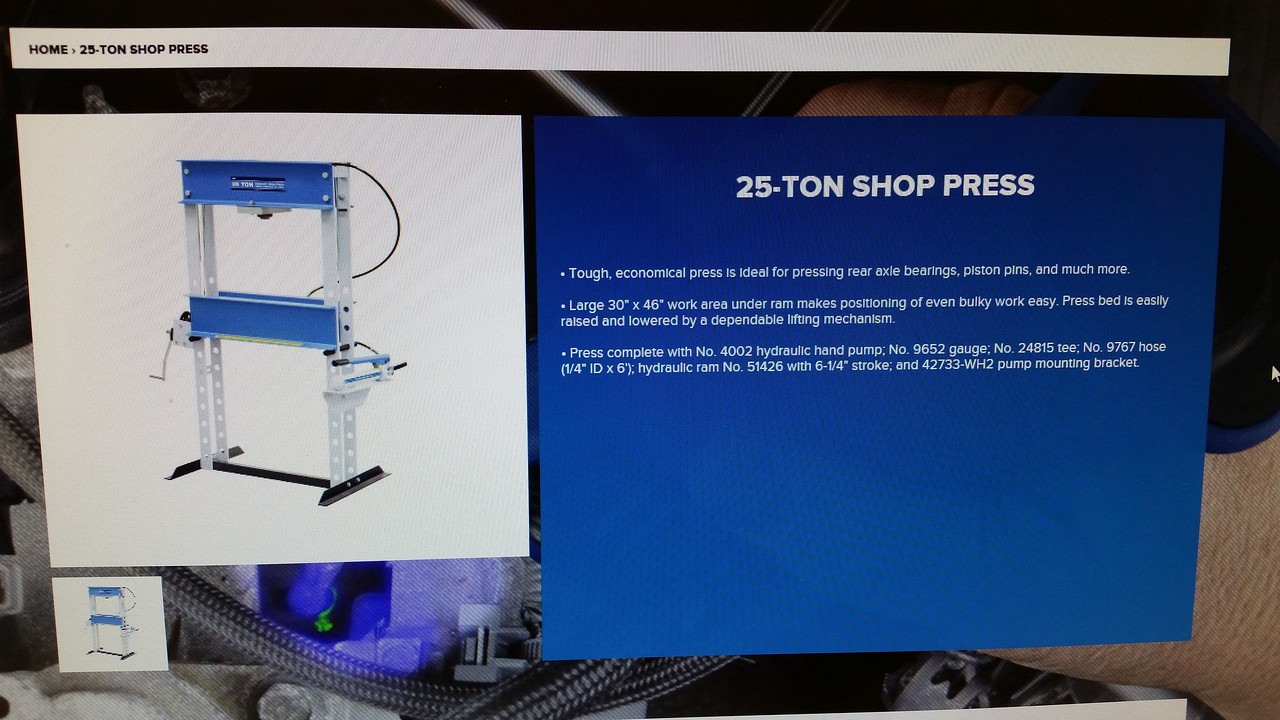

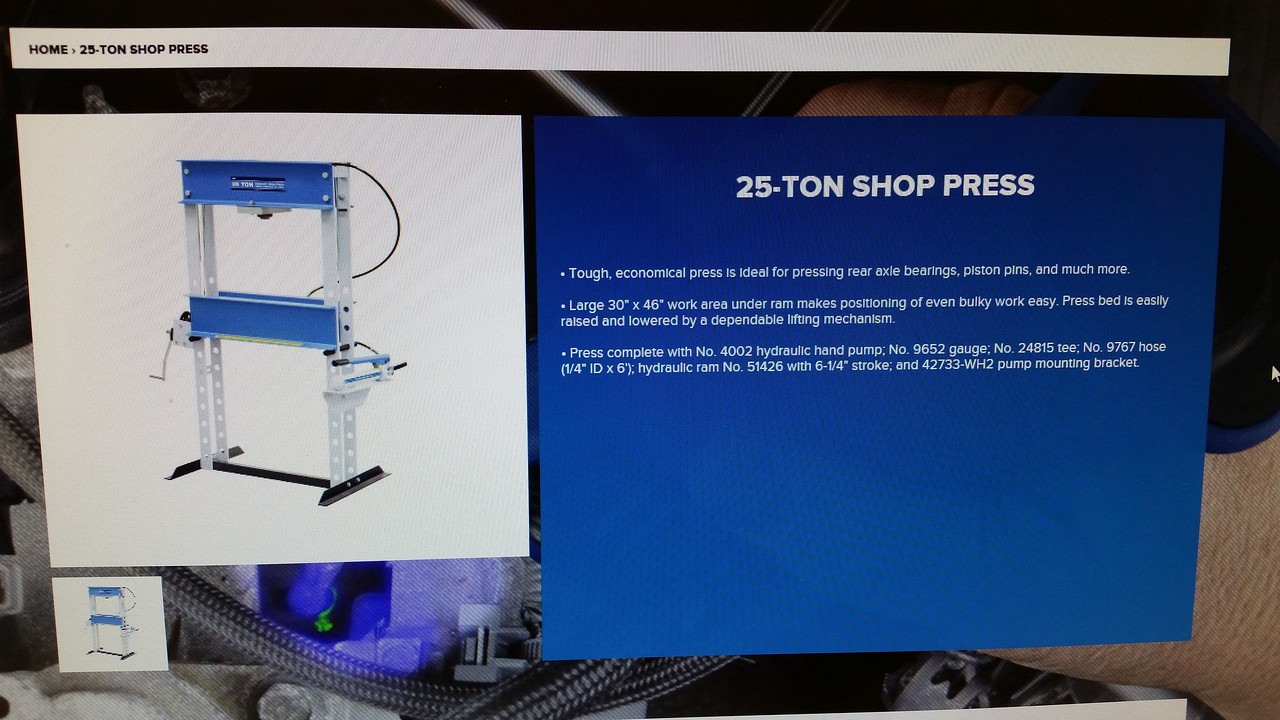

I am planning to retire in June of this year and I will not longer have access to a hydraulic press after that. I am putting together the necessary materials to build one similar to one we have at work that looks like this.

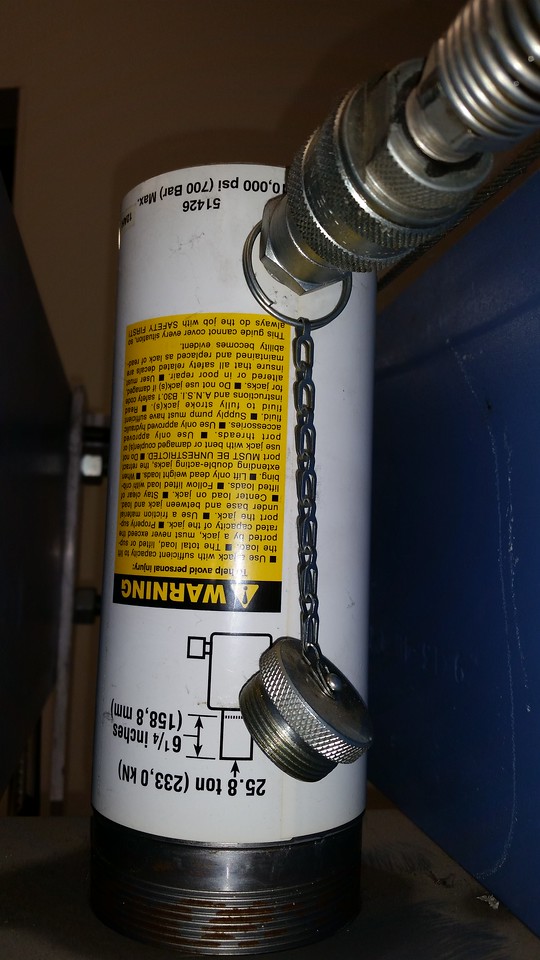

I have already got a 25 ton cylinder like this

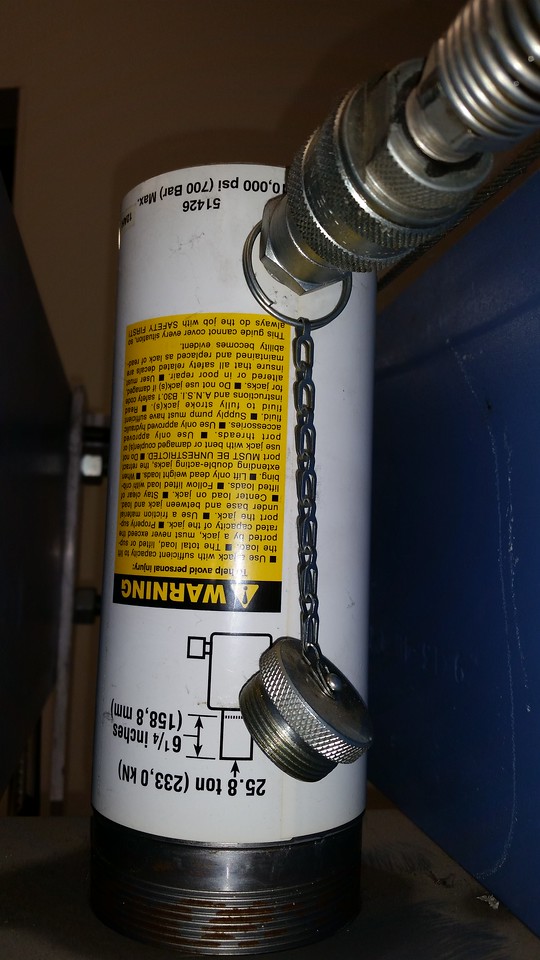

I have a source for a 10000 psi hand operated pump like this for $180

I'm hoping that someone here may have some steel that is suitable for the frame cross members. I'm looking for something similar to the 8" by 2.5" C channel with about 1/4" web thickness. Ideally I need 4 pieces around 3 feet long. I may also go with 2" by 6" rectangular tubing with 1/4" wall thickness. I have a source for this material but would need to buy a 20 foot length ($150).

https://www.kijiji.ca/v-business-in...KQiTrcevxMsLbLa9u8AOhG_O_VrLPOZTB7ZEe7IOfFosI

So If anyone has some steel that may be suitable please let me know and maybe we can make a deal and I could pick it up at the Modern Tool meet up this Saturday.

Cheers,

I have already got a 25 ton cylinder like this

I have a source for a 10000 psi hand operated pump like this for $180

I'm hoping that someone here may have some steel that is suitable for the frame cross members. I'm looking for something similar to the 8" by 2.5" C channel with about 1/4" web thickness. Ideally I need 4 pieces around 3 feet long. I may also go with 2" by 6" rectangular tubing with 1/4" wall thickness. I have a source for this material but would need to buy a 20 foot length ($150).

https://www.kijiji.ca/v-business-in...KQiTrcevxMsLbLa9u8AOhG_O_VrLPOZTB7ZEe7IOfFosI

So If anyone has some steel that may be suitable please let me know and maybe we can make a deal and I could pick it up at the Modern Tool meet up this Saturday.

Cheers,