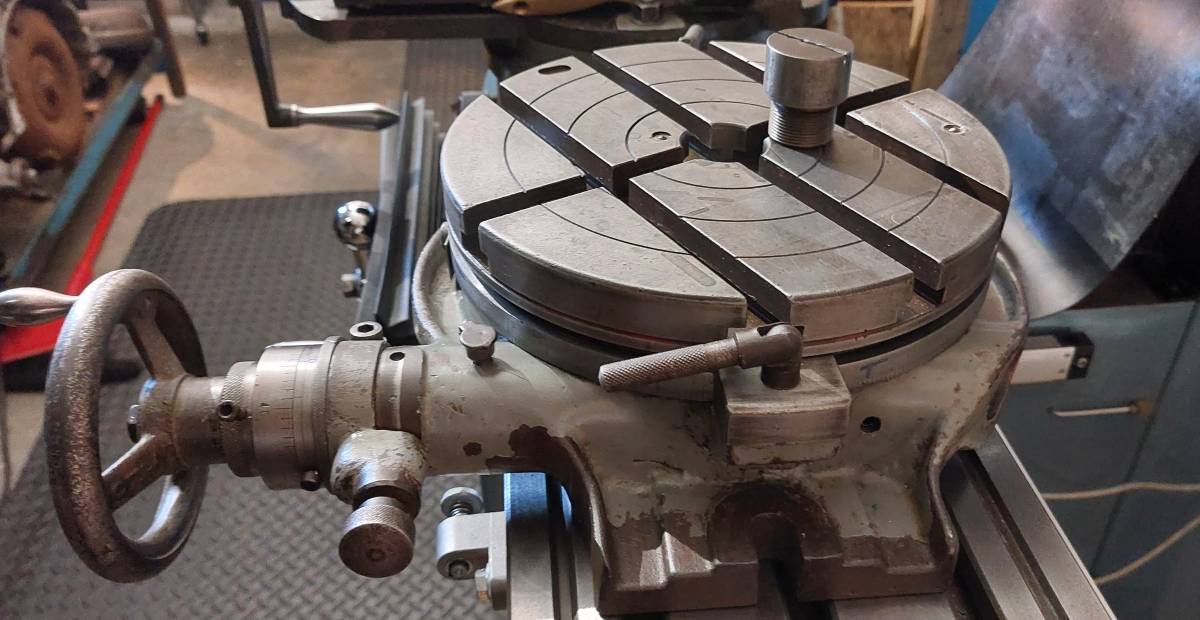

Perhaps a stupid question, but when looking one of these over, what easy tests can be made for wear/usability?

1. backlash in the rotation pinion/gear? What is typical?

2. slop in the table, either up or down, or sideways?

3. rocking of the base when unbolted from the table?

4. Parallel test of the platform relative to the table where it is mounted (when bolted)?

Any other things? With this being a horizontal only table, it may not attract as much attention. For those of us with universal mills, I suppose the vertical mode is less important as we can get that from the horizontal spindle. Or am I missing something.