My son and I have been enjoying the new mill and decided to install a 3-axis DRO on our new KC-20VS-2 mill. I decided to take a few pics of the install.

Fortunately there are many videos\forum posts on installing a DRO on the G0704 - this mill is almost exactly the same so I had lots of good ideas for mounting the scales.

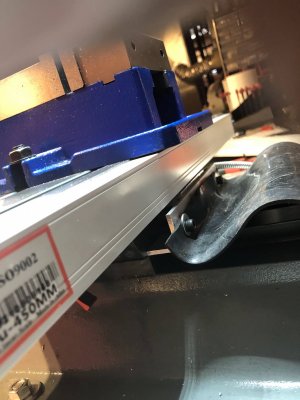

The y-axis required the most work. I decided to fix the reader and have the scale move. The thinking being there would be less wear and tear on the cable going to reader.

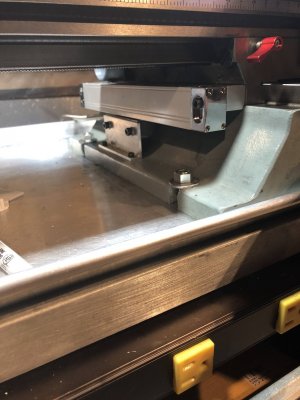

I used a 12" piece of .75 x .75 square stock to mount the scale:

We had to machine the edge of the piece to clear the base:

Since nothing is square on the base, I had to shim the l-bracket.

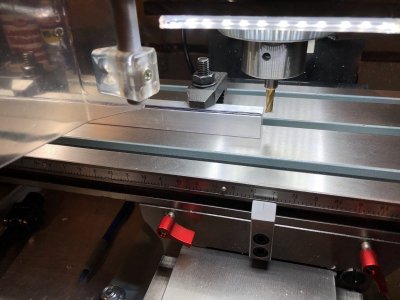

The x-axis was much more straight forward. Only had to drill 2 house to hold the scale. I reused the existing holes in the y-axis that holds the way cover to hold a piece of l bracket to hold the reader:

Finally the z-axis was very straight forward. We had to machine out a bracket to mount the reader to the head:

Finally the DRO head unit:

We started playing around with some of the functions - pretty cool little toy! Now we need to find some projects to work on

Fortunately there are many videos\forum posts on installing a DRO on the G0704 - this mill is almost exactly the same so I had lots of good ideas for mounting the scales.

The y-axis required the most work. I decided to fix the reader and have the scale move. The thinking being there would be less wear and tear on the cable going to reader.

I used a 12" piece of .75 x .75 square stock to mount the scale:

We had to machine the edge of the piece to clear the base:

Since nothing is square on the base, I had to shim the l-bracket.

The x-axis was much more straight forward. Only had to drill 2 house to hold the scale. I reused the existing holes in the y-axis that holds the way cover to hold a piece of l bracket to hold the reader:

Finally the z-axis was very straight forward. We had to machine out a bracket to mount the reader to the head:

Finally the DRO head unit:

We started playing around with some of the functions - pretty cool little toy! Now we need to find some projects to work on