Why would I really need (want) a SG?

I was waiting for others to chime in because I know I don't get full use out of mine and I'd love to hear what others do with theirs. Fundamentally, surface grinders make precision surfaces. The height dial is typically calibrated in 10ths and its not hard to hit a 10ths target. Typically, mine is used to make tools for my tools! I have not used mine to sharpen tools, but I'd like to. Here is what I have used mine for:

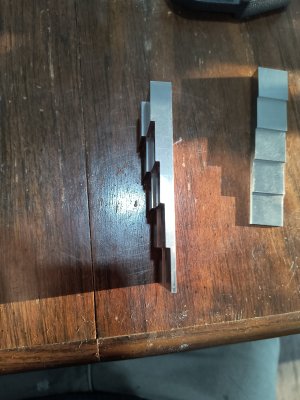

1. Making identical custom gauge blocks. Buy the regular stuff cuz they are cheap. But custom stuff is expensive so make it instead.

2. A set of height blocks to set a sine plate. They can be stamped with the angle they make.

3. Three identical 3.5" blocks to raise a brake disk above my vise on my mill table for tramming. Grinding all 3 at once guarantees equal height and parallel surfaces. The exact height isn't important, but equal height and parallel is.

4. Making drop dead gorgeous very flat surfaces on larger parts - beautiful mirror like surfaces. It seems like most of my surfaces were good enough before I got the grinder. Now everything needs grinding.... LOL!

5. Making custom height parallels.

5. Making angle blocks

7. Making balances - you can make your own balancer for the wheel. An unbalanced wheel is good enough to make a balancer! You can always go back and improve the finish after you use it to balance the wheel.

8. Matching surfaces. Perhaps matching head and block on a small engine but I have not done that. I have matched two sliding surfaces though.

I can't wait to hear what others are doing.

It is said to be running, what do I look for to know if it’s worth dragging home of walking away?

A good spindle, good ways, and smooth cranks.

Make sure you block the spindle and bed for travel.

What kind of a black hole is a SG for $? What needs to be bought to run it?

Not nearly like a mill or a lathe.

Should come with a mag vise

Various Wheels

Wheel Balancer

More 10ths metrology - LOL!

Diamond Wheel Dresser

Wheel arbours (this adds up)

Wheel wrenches

Grinding vises

Angle grinding vise

Vacuum to catch the dust

5C Tooling holder & collets

With 3 ground in set angles

Table based dust shield

Looking forward to hearing what others have and use.