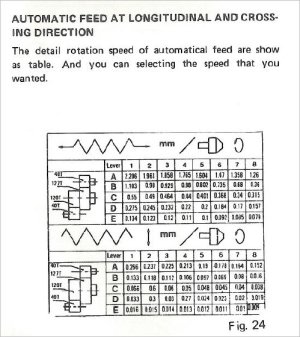

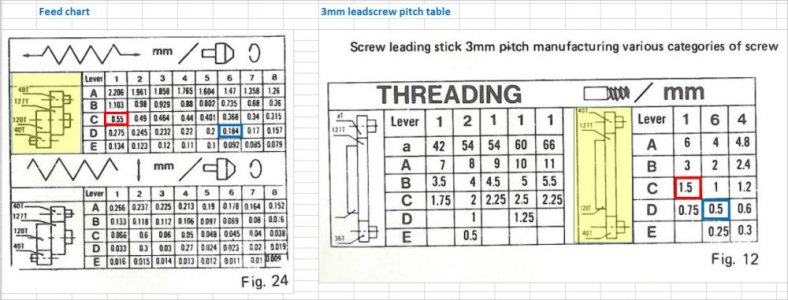

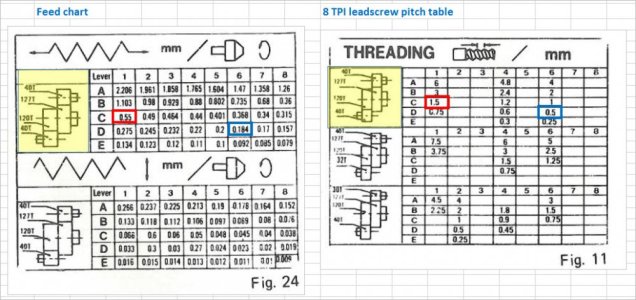

I have this funky chart too & assumed it is feed rates? They show the headstock gear combination but no mention of which corresponding leadscrew (8 TPI or 3mm).

This has always puzzled me thinking there should be some math correlation to a longitudinal feed value on this table and screw pitch on prior table, assuming the same lever combination. But I cant see anything that computes. So either I'm not getting it, or maybe under powerfeed (vs threading select) a different or default drive gear is coming into play? Fortunately I never pay attention to feed rates haha

EDIT

There probably should be no correlation to feed rates & some multiple of thread pitch because the powerfeed bar is driving completely different set of gears in the apron in order to traverse the carriage & cross slide.

EDIT

There probably should be no correlation to feed rates & some multiple of thread pitch because the powerfeed bar is driving completely different set of gears in the apron in order to traverse the carriage & cross slide.

Attachments

Last edited: