SomeGuy

Hobbyist

Would like a second chuck for my lathe, mostly because I just have a keyed chuck and doing a center drill, pilot drill, drill to size, and then chamfer takes forever swapping bits.

Requirements:

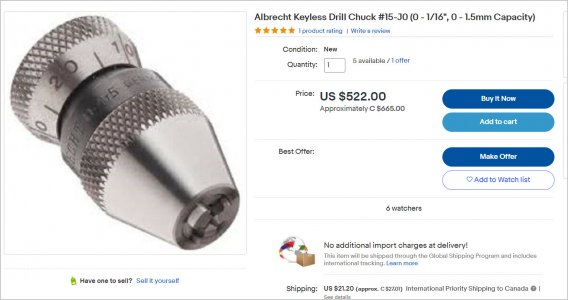

- Keyless Chuck

- 5/8" or so size, not a 1/2" since I have a few bits that are quite snug in that

- MT3 taper - I see you can get integrated or a separate chuck and arbor, what's better?

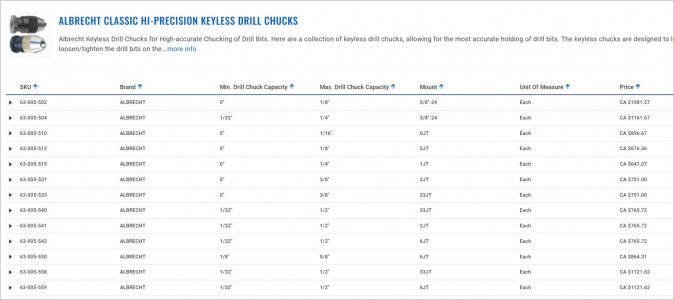

- Affordable - Don't feel like spending $500+ on a Jacobs right now

Requirements:

- Keyless Chuck

- 5/8" or so size, not a 1/2" since I have a few bits that are quite snug in that

- MT3 taper - I see you can get integrated or a separate chuck and arbor, what's better?

- Affordable - Don't feel like spending $500+ on a Jacobs right now