Tomc938

Ultra Member

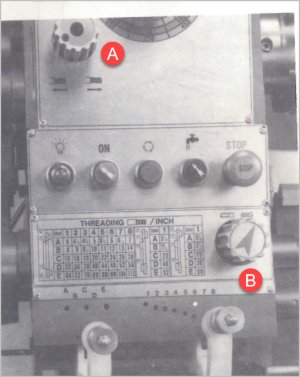

So my King lathe (1236) is a belt drive with a QCGB. There is a knob that allows you to change the direction of the feed. (in cross and longitudinal feed)

Last night I needed to change the direction of feed and switched to the other position on the knob. I had to turn the chuck a bit to allow the mechanism to sync the gears. I noticed a bit of a catch between the two positions. Just for fun I left it in that position and turned on the lathe. To my surprise it fired right up, and worked great! And absent was the "clatter" of the gears in the box. So I guess there is a neutral position, not mentioned in the manual, where the spindle runs but the gear box does not. I've had the lathe for a year or so, and longed for the sound of a belt drive lathe without the gears running all the time. I'm going to bet everything in the QCGB will last WAY longer if they are not constantly running.

Am I the only one who didn't know about neutral on the gear box direction knob?

Last night I needed to change the direction of feed and switched to the other position on the knob. I had to turn the chuck a bit to allow the mechanism to sync the gears. I noticed a bit of a catch between the two positions. Just for fun I left it in that position and turned on the lathe. To my surprise it fired right up, and worked great! And absent was the "clatter" of the gears in the box. So I guess there is a neutral position, not mentioned in the manual, where the spindle runs but the gear box does not. I've had the lathe for a year or so, and longed for the sound of a belt drive lathe without the gears running all the time. I'm going to bet everything in the QCGB will last WAY longer if they are not constantly running.

Am I the only one who didn't know about neutral on the gear box direction knob?