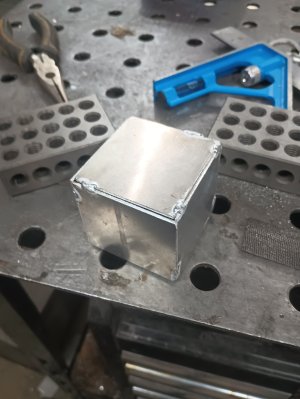

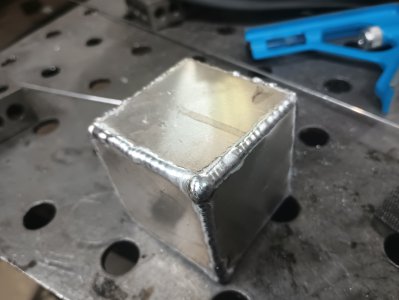

So, I had a small (should have been small) welding project come up. TIG weld an aluminum duct up for the oil cooler in my RV4. For size, the cooler surface is about 6" x 6" and the height will be about 3". After several days of practice, and some premature attempts at the actual project, I have realized that I still need more practice! The small welding project has become a mission to learn to at least do an acceptable tig project. I can do "OK" running beads on flat stock on a bench, but sometimes struggle when it comes to join 2 parts at a corner. So I decided to stop practicing on flat stock and small chunks of stock set up as an angle. I figure welding a small project that more closely replicates an actual project would be better than to keep burning gas and filler on random beads. A 2" cube is actually 24" of welding, all outside corners (like my project will be) and includes several starts, tacks, dealing with the metal getting hotter, etc....

As I was looking for welding info here, and on the web, I found a lot of threads in which someone, like me, is looking for input, or advice, etc. I did not want to post the same questions that are often posted..."my welds are crappy, what should I do?" So.....

I know that there are several accomplished welders on this forum, some beginners, and many in between. So I figured I would throw this out there. Maybe some will have fun with it. I will submit my first attempt. I am going to keep making these aluminum dice until I feel I am happy with one or two. This first one is pretty ugly. If anyone wants to do one up and post great! Maybe it will inspire some to do one up for their own satisfaction/challenge! Maybe you good welders will do one up to show us beginners how it can be done. Or maybe no one will read this post.....

I will say that because of this exercise, I was forced to learn a new appreciation for gas flow, cup size, reading tungsten indications, what the balance control actually does, etc. I even (gasp!) got out the welder manual and read about some of the controls!

For those not into TIG, do it with a MIG, or if you are cocky, stick, or even gas fusion. Try to keep them around 2" square. Hoping some of you jump in.

Although the point of this thread is, for those interested, to have some fun with a small welding practice project, I included photos of the oil cooler plenum that will be my actual goal. I have friends that could do a very nice job on it, and it would have been done days ago, but sometimes I want to beat my head on the wall until I learn something. This is one of those times I guess.

Cheers,

Shawn

As I was looking for welding info here, and on the web, I found a lot of threads in which someone, like me, is looking for input, or advice, etc. I did not want to post the same questions that are often posted..."my welds are crappy, what should I do?" So.....

I know that there are several accomplished welders on this forum, some beginners, and many in between. So I figured I would throw this out there. Maybe some will have fun with it. I will submit my first attempt. I am going to keep making these aluminum dice until I feel I am happy with one or two. This first one is pretty ugly. If anyone wants to do one up and post great! Maybe it will inspire some to do one up for their own satisfaction/challenge! Maybe you good welders will do one up to show us beginners how it can be done. Or maybe no one will read this post.....

I will say that because of this exercise, I was forced to learn a new appreciation for gas flow, cup size, reading tungsten indications, what the balance control actually does, etc. I even (gasp!) got out the welder manual and read about some of the controls!

For those not into TIG, do it with a MIG, or if you are cocky, stick, or even gas fusion. Try to keep them around 2" square. Hoping some of you jump in.

Although the point of this thread is, for those interested, to have some fun with a small welding practice project, I included photos of the oil cooler plenum that will be my actual goal. I have friends that could do a very nice job on it, and it would have been done days ago, but sometimes I want to beat my head on the wall until I learn something. This is one of those times I guess.

Cheers,

Shawn