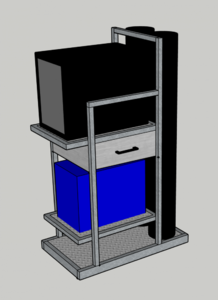

I spent some time with SketchUp last night and this morning. This is what I came up with.

I couldn't figure out how to make radius corners but I will have radius corners on the upright in front of the tanks and the front corners of the shelves.

Oh and it will have casters

32" long, 18" wide, 4 ft tall

Two 110 cu ft tanks

TIG on top

MIG on bottom

Side opening drawer under the TIG

Bottom shelf for TIG pedal, although I could make a bracket/holder on the side.

I didn't add cable hangers yet.

I couldn't figure out how to make radius corners but I will have radius corners on the upright in front of the tanks and the front corners of the shelves.

Oh and it will have casters

32" long, 18" wide, 4 ft tall

Two 110 cu ft tanks

TIG on top

MIG on bottom

Side opening drawer under the TIG

Bottom shelf for TIG pedal, although I could make a bracket/holder on the side.

I didn't add cable hangers yet.