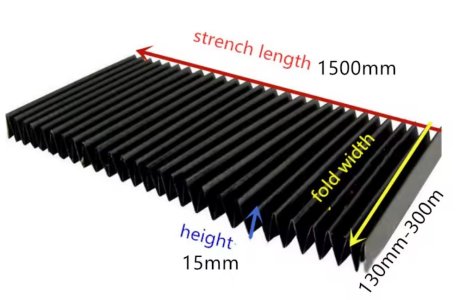

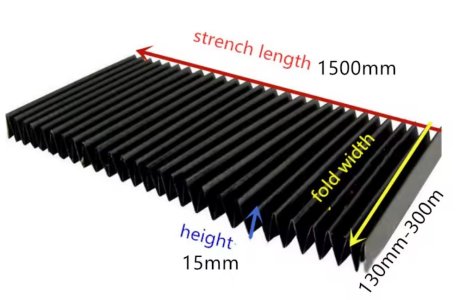

I'm thinking of ordering this from AliExpress

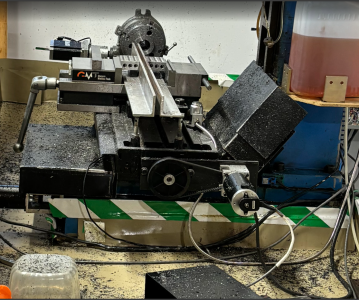

to cover the naked front part of the Y Axis on my mill.

The back end of the Y axis is already covered and it's pretty obvious how chip laden it gets and is at times hard to vacuum out but it does protect the ways so seems a good idea to protect the front too.

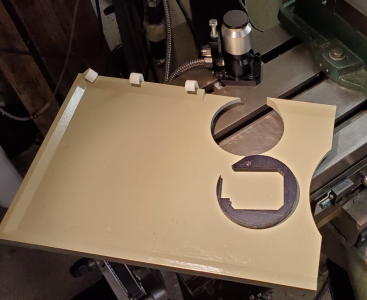

Now the Z axis ways are not covered. I see photos of Bridgeports with some sort of heavy thick rubber fastened at the top. Not sure how it's fastened at the bottom.

On my mill the table only goes as high as that rubber stop.

.

.

Suggestions as to what to use for Z axis?

to cover the naked front part of the Y Axis on my mill.

The back end of the Y axis is already covered and it's pretty obvious how chip laden it gets and is at times hard to vacuum out but it does protect the ways so seems a good idea to protect the front too.

Now the Z axis ways are not covered. I see photos of Bridgeports with some sort of heavy thick rubber fastened at the top. Not sure how it's fastened at the bottom.

On my mill the table only goes as high as that rubber stop.

.

.Suggestions as to what to use for Z axis?