trlvn

Ultra Member

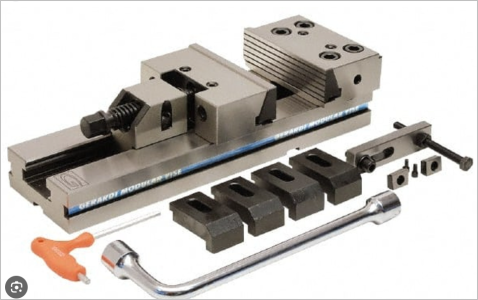

My (current?) vise has mounting tabs both on the side and the ends of the vise, see below.

Theoretically, I have about 8 inches of Y travel. Since I installed a DRO scale on the column side, that should leave me with about 7 inches usable. However, the widest piece I can mill **in the vise** is just less than 4.5 inches because the fixed jaw can't get closer to the column than about 3.5 inches. The tab on the front of the vise hits the column of the mill.

If I removed the front tab, I could install the vise using the T-slot closer to the column and gain about 1.5 inches of usable Y.

So, 2 questions:

1) What bad things will happen to my vise if I hack off the front tabs? (Probably I should just replace the vise I don't like just throwing money at every little problem.)

2) What bad things will happen if I install the vise in using the front T-slot rather than the middle one?

Thanks,

Craig T.

Theoretically, I have about 8 inches of Y travel. Since I installed a DRO scale on the column side, that should leave me with about 7 inches usable. However, the widest piece I can mill **in the vise** is just less than 4.5 inches because the fixed jaw can't get closer to the column than about 3.5 inches. The tab on the front of the vise hits the column of the mill.

If I removed the front tab, I could install the vise using the T-slot closer to the column and gain about 1.5 inches of usable Y.

So, 2 questions:

1) What bad things will happen to my vise if I hack off the front tabs? (Probably I should just replace the vise I don't like just throwing money at every little problem.)

2) What bad things will happen if I install the vise in using the front T-slot rather than the middle one?

Thanks,

Craig T.