-

Scam Alert. Members are reminded to NOT send money to buy anything. Don't buy things remote and have it shipped - go get it yourself, pay in person, and take your equipment with you. Scammers have burned people on this forum. Urgency, secrecy, excuses, selling for friend, newish members, FUD, are RED FLAGS. A video conference call is not adequate assurance. Face to face interactions are required. Please report suspicions to the forum admins. Stay Safe - anyone can get scammed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vertical Shear Tool

- Thread starter YYCHM

- Start date

No, a lathe tool. It might be called a finishing tool as well? Suppose to give a very smooth finish. Very simple, just two faces to grind, but I don't know what the face angles should be.You mean like scissors?

Proxule

Ultra Member

Shear tools for lathe work. - HomemadeTools.net

Hands up all those who know what a shear lathe tool bit is. How many of you have ever tried one? Personally I think these tool bits should better be

www.homemadetools.net

Vertical Shear Bit

A simple to grind lathe finishing tool that works exceptionally well

gadgetbuilder.com

Im not sure if the angles @YYCHM . I use them all the time. The angles are not critical. It's one of the things I like about them.

The idea is indeed to make them cut like a scissor blade. For a normal facing cut, I make the vertical angle 10 degrees or less with a very sharp edge and some back rake they are not critical on height setting either. You can cut on any part of the vertical face. And in fact you can maintain a sharp cut just by sharpening the entire edge and then moving the bit up or down to obtain a fresh edge.

You will know you have it right when it makes very fine steel wool. The feed rate and depth of cut must be low. A shear tool will leave a really nice surface when nothing else will.

If you want, I'll take a few pictures of some of my bits.

The idea is indeed to make them cut like a scissor blade. For a normal facing cut, I make the vertical angle 10 degrees or less with a very sharp edge and some back rake they are not critical on height setting either. You can cut on any part of the vertical face. And in fact you can maintain a sharp cut just by sharpening the entire edge and then moving the bit up or down to obtain a fresh edge.

You will know you have it right when it makes very fine steel wool. The feed rate and depth of cut must be low. A shear tool will leave a really nice surface when nothing else will.

If you want, I'll take a few pictures of some of my bits.

A few other pointers @YYCHM. The biggest issue with a shear tool is getting swarf into the cutting action. That will bugger up the final finish. Some sources suggest a chip breaker. I've tried that but it doesn't really help and it makes the cutting edge harder to do.

In case it isn't obvious, I am a big fan of shear tools!

In case it isn't obvious, I am a big fan of shear tools!

Im not sure if the angles @YYCHM . I use them all the time. The angles are not critical. It's one of the things I like about them.

The idea is indeed to make them cut like a scissor blade. For a normal facing cut, I make the vertical angle 10 degrees or less with a very sharp edge and some back rake they are not critical on height setting either. You can cut on any part of the vertical face. And in fact you can maintain a sharp cut just by sharpening the entire edge and then moving the bit up or down to obtain a fresh edge.

You will know you have it right when it makes very fine steel wool. The feed rate and depth of cut must be low. A shear tool will leave a really nice surface when nothing else will.

If you want, I'll take a few pictures of some of my bits.

Looks like the angles aren't critical. I ground one up with 15 deg vertical and 10 deg back rake. As you say it produced very fine steel wool swarf and a beautiful smooth finish.

Yup, not critical at all.

I measured my favorite just now. The vertical angle and the back rake are both someplace between 5 and 7 degrees.

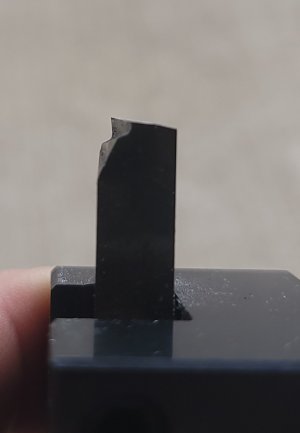

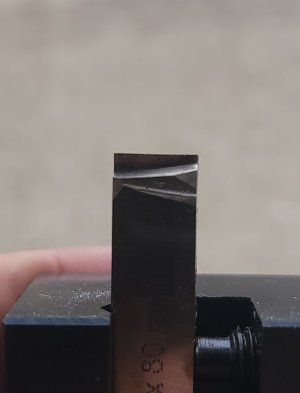

Here are some photos of my goto tool. This one was recently reground. I usually polish them too. But it sounds like you are all set.

Face view

Top View

Chuck side view

This one has an old chip breaker on it that never worked worth a crap. Just go slow with minimum feed rate and depth of cut.

FWIW, a shear blade is also a very good way to take a very small cut. Mine easily handles cuts under 1 thou.

When the cutting edge gets a bit dull, just raise or lower the blade so it cuts a bit higher or lower on the edge.

I measured my favorite just now. The vertical angle and the back rake are both someplace between 5 and 7 degrees.

Here are some photos of my goto tool. This one was recently reground. I usually polish them too. But it sounds like you are all set.

Face view

Top View

Chuck side view

This one has an old chip breaker on it that never worked worth a crap. Just go slow with minimum feed rate and depth of cut.

FWIW, a shear blade is also a very good way to take a very small cut. Mine easily handles cuts under 1 thou.

When the cutting edge gets a bit dull, just raise or lower the blade so it cuts a bit higher or lower on the edge.

Last edited:

Something I've always wondered about @YYCHM . What would happen if you increase the stock size to 3" OD or so?

That flat vertical face might not work so well. In that case, I think a curved face might be required to keep the bit from cutting along its entire edge. You would lose the ability to adjust up or down to maintain a sharp edge and it would have to be height adjusted, but it should still work. Someday I'll try it - prolly when the need arises.

That flat vertical face might not work so well. In that case, I think a curved face might be required to keep the bit from cutting along its entire edge. You would lose the ability to adjust up or down to maintain a sharp edge and it would have to be height adjusted, but it should still work. Someday I'll try it - prolly when the need arises.