You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool Post Locking Lever - Where to Buy?

- Thread starter YYCHM

- Start date

Hey Craig I made mine so easy to do, love playing with my different sized balls. Can even play with them should the power go down and know what I'm doing. LOL

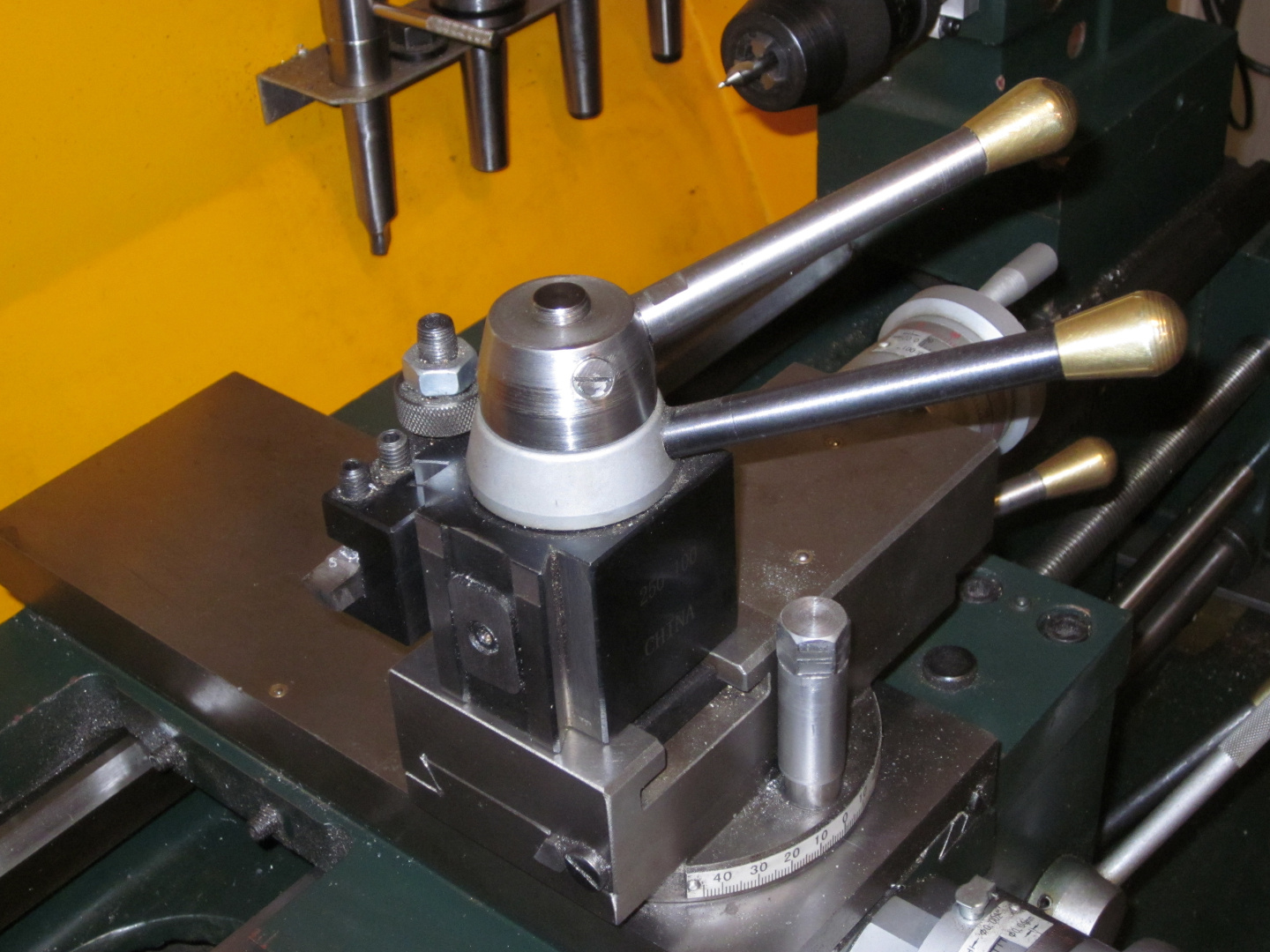

When my QCTP is locked up tight (meaning crown nut) with tooling installed the handles do not over hang the work piece area for obvious safety reasons and better access for changing out centers, drill bits, reamers, etc.

Have never run across them for sale.

When my QCTP is locked up tight (meaning crown nut) with tooling installed the handles do not over hang the work piece area for obvious safety reasons and better access for changing out centers, drill bits, reamers, etc.

Have never run across them for sale.

Attachments

Last edited:

VicHobbyGuy

Ultra Member

Buy?> tsk, tsk....Have you ever come across these for sale anywhere?

I thought about something similar but decided that :

a) it would need a lot of faffing about, either machining, or adding/subtracting shims to get the handle in the right (2-3 o'clock, like @Dusty's ) position

b) a wrench or socket on a handle would be more convenient for me since it can just live in the tray most of the time.

Buy?> tsk, tsk....

I thought about something similar but decided that :

a) it would need a lot of faffing about, either machining, or adding/subtracting shims to get the handle in the right (2-3 o'clock, like @Dusty's ) position

b) a wrench or socket on a handle would be more convenient for me since it can just live in the tray most of the time.

My take on your comments. My QCTP locking leaver hung over the work area which I didn't appreciate for obvious safety reasons. By facing some of the material from the bottom of the crown nut (for want of a word) did the trick and you really don't need to remove much material to adjust the handle to a safer position.

Been there done that have the 'T' shirt. LOL

Last edited:

mickeyf

Well-Known Member

I took a socket (.50 at Restore, might be less at a yard sale) and welded on a piece of rod for a handle. Coupla minutes work. Doesn't look as pretty as the one in the photo, but does the job. If I decide some day that I want one that displays high craftsmanship I can still do that.

The ball isn't easy to make so I bookmarked an Ali item with threaded brass insert balls. I didn't buy any, but I saw them and thought of this problem and a few others too - eg the belt tensioner arm on my mill.

Someday I will make a ball turner for my lathe.

The handle is easy to make.

Indexing the handle to keep it out of the way is as easy as removing less than a thread width on the face of the nut.

Former Member

Guest

@Dusty I was just chewing some food reading your post and almost choked laughing.....Hey Craig I made mine so easy to do, love playing with my different sized balls. Can even play with them should the power goes down and know what I'm doing. LOL

When my QCTP is locked up tight with tooling installed they do not over hang the work piece for safety reasons and better access while changing drill bits, reamers, etc.

Have never run across them for sale.

You're playing with your different sized balls????

I thought this site was PG rated

@Dusty I was just chewing some food reading your post and almost choked laughing.....

You're playing with your different sized balls????

I thought this site was PG rated

@Degen what are you thinking your mind wondered to the wrong work bench. I knew someone would pick up on my comments. LOL

Didn't mean for you to almost choke. Sorry!

When I first started watching John Mills ("doubleboost" on YouTube) years ago, I liked his idea of a locking handle, similar to the one in the top picture. I made mine out of scrap pieces on hand when I first got my lathe. It is handy but I admit that the lever itself can get to be a pain so I think I might go back to the original nut and bend a wrench for it like Keith Fenner did for his large lathe tool post. That way it can be locked down and the "handle" removed, yet it will still easily clear the tool holder locking lever.

Attachments

VicHobbyGuy

Ultra Member

Hey Craig I made mine so easy to do

What dia and length is the nut?

@YYCHM Hey Craig you are aware my QCTP is an AXA wedge style.

Handle in my Phase 11 QCTP is 1/2" diameter - 4 & 1/4 " long - with 1 & 1/4 " diameter red ball. Handle in my crown nut is 3/4" diameter - 4 & 3/4 " long - with 1 & 7/8 " black ball with threaded brass insert. Both handles are more-or-less on the same angle both with wrench flats.

Crown nut at the base is 1 & 1/2" diameter - 2 & 7/16 " overall height - 1" diameter top with 18 degree angle which on the flat is 23/32 " long.

Hope this helps your project.

Handle in my Phase 11 QCTP is 1/2" diameter - 4 & 1/4 " long - with 1 & 1/4 " diameter red ball. Handle in my crown nut is 3/4" diameter - 4 & 3/4 " long - with 1 & 7/8 " black ball with threaded brass insert. Both handles are more-or-less on the same angle both with wrench flats.

Crown nut at the base is 1 & 1/2" diameter - 2 & 7/16 " overall height - 1" diameter top with 18 degree angle which on the flat is 23/32 " long.

Hope this helps your project.

Attachments

Last edited:

@YYCHM Hey Craig you are aware my QCTP is an AXA wedge style.

Handle in my Phase 11 QCTP is 1/2" diameter - 4 1/4 " long - with 1 1/4 " diameter red ball. Handle in my crown nut is 3/4" diameter - 4 3/4 " long - with 17/8 " black ball with threaded brass insert. Both handles are more-or-less on the same angle with wrench flats.

Crown nut at the base is 1 & 1/2" diameter - 2 & 7/16 " overall height - 1" diameter top with 18 degree angle which on the flat is 23/32 " long.

Hope this helps your project.

This is downright beautiful.

I love it. I even like the two different coloured balls.

140mower

Don

Especially since they aren't blueThis is downright beautiful.

I love it. I even like the two different coloured balls.

J/k..... Looks great.

140mower

Don

..... Had phone in pocket......

Well.... After much dithering.....

View attachment 25231

I broke down and made one. So far I'm liking it, no more reaching for a wrench to change tool position.

Too tall?

NICE Craig!

I don't think it's too tall. My hands would not fit if it were much shorter.

I'd prolly replace the bottom ball with one like the top if it were mine. Or vice versa.