slow-poke

Ultra Member

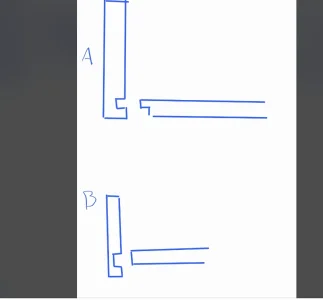

My name is Slowpoke and I have a tool box problem. It all started when I purchased a new mill that required R8 tooling and the roll around "mill tools" box that lives adjacent to the mill was a drawer or so short for the required new tooling.

Fortunately some of the tools in the mill toolbox would be better located in the workbench toolbox, however there were no spare drawers there either, so I made a little tool chest to compliment the existing one. It's a little bit rough around the edges (first time);-)

So with what I learned from the first tool box build I'm now thinking of building another one so I can migrate even more tools over from the mill tool box. I'm going to shuffle things around a bit, the lathe is going to turn 90 degrees so the spindle side is unobstructed for long stock, and the drill press will move were the lathe is now. This shuffle will open up some wall space so I can move the drill indexes presently above the work bench to the wall freeing up space for the Mark II tool chest. Picture posted below after a long over due cleanup that took all of yesterday (Susquatch is going to love it). )-)

So now I have a wood related question......

The space available will be up to 30" wide and 12" deep. I don't anticipate heavy loads but things like gauge blocks could approach say 20 lbs? per drawer. Can't afford to have saggy drawers in the the long run and if the drawer bottoms are too thick that ends up wasting a lot of precious vertical space. Assuming I use wood for the drawer bottoms and considering the span say about 26", is this best built with plywood or solid wood and what thickness to prevent long term sag?

I'm not against using something other than wood for the drawer bottoms if that makes sense, comments welcome.

Fortunately some of the tools in the mill toolbox would be better located in the workbench toolbox, however there were no spare drawers there either, so I made a little tool chest to compliment the existing one. It's a little bit rough around the edges (first time);-)

So with what I learned from the first tool box build I'm now thinking of building another one so I can migrate even more tools over from the mill tool box. I'm going to shuffle things around a bit, the lathe is going to turn 90 degrees so the spindle side is unobstructed for long stock, and the drill press will move were the lathe is now. This shuffle will open up some wall space so I can move the drill indexes presently above the work bench to the wall freeing up space for the Mark II tool chest. Picture posted below after a long over due cleanup that took all of yesterday (Susquatch is going to love it). )-)

So now I have a wood related question......

The space available will be up to 30" wide and 12" deep. I don't anticipate heavy loads but things like gauge blocks could approach say 20 lbs? per drawer. Can't afford to have saggy drawers in the the long run and if the drawer bottoms are too thick that ends up wasting a lot of precious vertical space. Assuming I use wood for the drawer bottoms and considering the span say about 26", is this best built with plywood or solid wood and what thickness to prevent long term sag?

I'm not against using something other than wood for the drawer bottoms if that makes sense, comments welcome.

Last edited: