Hi all and John C. @Dabbler

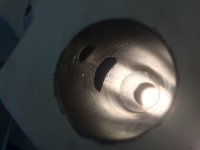

I have a new to me lathe 14x40, but the tailstock is giving me some trouble. The spindle won't feed properly and binds up when turning the handle or just trying to slide it. I took it all apart and cleaned and cleaned. There were some burrs on the oiler holes which I resolved but after cleaning it all again and shining a bright light on it I finally noticed these score marks on the inside. The worst one I can catch a finger nail on. I can't see anything else wrong - would this be enough to cause binding?

I was thinking of wrapping 600 grit sand paper on a dowel to clean it up. Is this a bad idea? Is there a better way? Thoughts? Thanks for any help...

John

I have a new to me lathe 14x40, but the tailstock is giving me some trouble. The spindle won't feed properly and binds up when turning the handle or just trying to slide it. I took it all apart and cleaned and cleaned. There were some burrs on the oiler holes which I resolved but after cleaning it all again and shining a bright light on it I finally noticed these score marks on the inside. The worst one I can catch a finger nail on. I can't see anything else wrong - would this be enough to cause binding?

I was thinking of wrapping 600 grit sand paper on a dowel to clean it up. Is this a bad idea? Is there a better way? Thoughts? Thanks for any help...

John