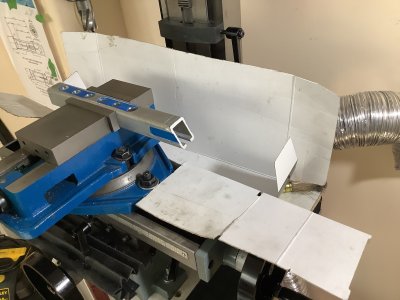

When I was milling out a BXA holder last week to take my rocker style ball turner, scarf was flying everywhere - further than usual. It was probably a result of the steel type. I didn't like it so I made some quick scarf shields out of cardboard. It wasn't prompted by your thread

@thestelster or I probably would have copied your idea. On the plus side, it's a different idea to consider.

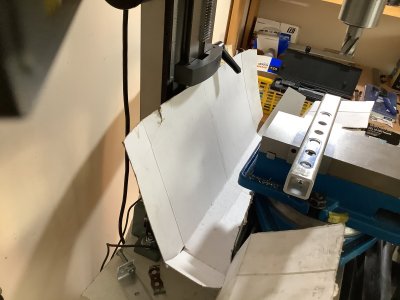

I cut the lids off of a cardboard box. I don't have them handy, but I'd say they were 8x24 or so - the size isn't important. Then I curled them around my work so they made a somewhat circular swarf shield. Perhaps I'll call it a swarf cage. The left one kept falling over so I cut some slits in it with a scissor and then stuck some small pieces of cardboard into the slits to function as feet.

It actually worked quite well. They are easily moved for setup and progress measurements and can be adjusted on the fly as the swarf fly's! I plan to make some improved versions as time passes to better fit my vice and table.

They are nothing special. But they were easy to make, configurable, super fast to adjust to the situation, and quite functional. Afterward, it was 100x easier to clean up the swarf too!

Just another idea!